Have you ever wondered how to make perfect cuts on a metal lathe? Achieving accuracy can be tricky, but it’s possible with the right setup. A metal lathe DRO setup brings a whole new level of precision to your work. Imagine cutting metal to the exact measurement every time without the guesswork.

Many hobbyists face challenges with traditional measuring tools. They rely on calipers and rulers, which can lead to mistakes. But with a digital readout (DRO), you can see exact measurements in real time. This can save time and reduce errors.

Interestingly, many skilled machinists claim that using a DRO transforms the way they work. They find that it boosts confidence and speed in their projects. Why not join them? By setting up a metal lathe DRO, you’ll turn ideas into reality more accurately!

Metal Lathe Dro Setup For Accuracy: Perfecting Precision

Metal Lathe DRO Setup for Accuracy

Setting up a metal lathe with a DRO, or digital readout, can drastically improve your accuracy. Did you know that a well-calibrated DRO helps in making precise cuts? With this setup, you can easily track measurements and minimize errors. Imagine creating projects where every detail counts! Learning how to set this up can change your machining experience. It’s a simple upgrade that brings big results, making your work more efficient and enjoyable.Understanding DRO: What is a Digital Readout?

Definition and purpose of a DRO in machining. Benefits of using a DRO over traditional measuring methods.A digital readout (DRO) is a tool that shows exact measurements on a screen. It helps machinists see where their tools are. This tool is important because it makes machining easier and more accurate.

Here are some benefits of using a DRO:

- Increases precision in cuts.

- Reduces human error from manual measuring.

- Speeds up the measuring process.

- Provides real-time data on positions.

By using a DRO, machinists can create better pieces and save time. It’s a smart choice for anyone working with metal.

What are the advantages of a DRO in machining?

DROs improve accuracy, reduce mistakes, and save time compared to manual methods. They offer clear displays, which help users see measurements instantly.

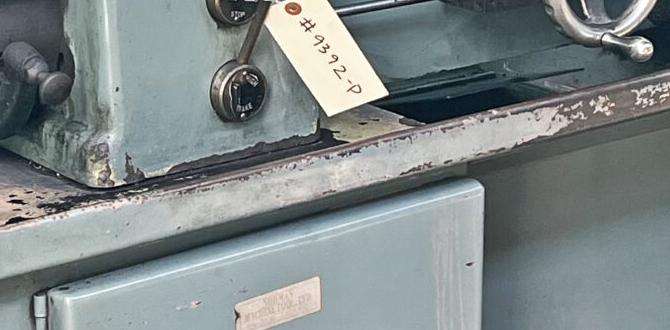

Components of a Metal Lathe DRO Setup

Key components involved in a DRO setup. Types of scales and their functions.A metal lathe DRO setup has some key components that help it work accurately. The most important parts include:

- Display Unit: This shows the measurements clearly.

- Scales: These come in different types. They can be linear or rotary.

- Sensors: They detect measurements and send data to the display.

- Wiring: Good wires connect everything together.

Linear scales are used for straight movements, while rotary scales measure circular motion. Together, these parts ensure the metal lathe provides precise accuracy. Proper setup helps in achieving better results and making professional projects easier.

What are the types of scales in a DRO setup?

Linear scales measure straight movements, while rotary scales focus on circular movements. Each type plays a unique role in ensuring good accuracy in machining tasks.

Choosing the Right DRO for Your Metal Lathe

Factors to consider when selecting a DRO. Comparing different brands and models based on accuracy and features.Choosing a good DRO for your metal lathe is important for precision. Here are some factors to consider:

- Accuracy: Check how precise the measurements are.

- Ease of Use: The DRO should be user-friendly.

- Features: Look for extra features that suit your work style.

- Brand Reputation: Popular brands often provide reliable quality.

Compare different models to find the best one for you. Each brand may have unique strengths, and understanding these can help you achieve better results.

What should I look for in a DRO?

Focus on accuracy, user-friendliness, and extra features. The right DRO can make a big difference in your work quality.

Considering these points will help you feel confident in your choice. A good DRO setup enhances your metal lathe accuracy, making your projects easier and more fun!

Step-by-Step Guide to Setting Up Your Metal Lathe DRO

Detailed setup instructions for optimal placement. Common mistakes to avoid during installation.Setting up a metal lathe DRO can feel a bit like solving a puzzle, but it’s easier than it sounds! First, find the perfect spot for the display. Make sure it’s easy to see and reach, like your snack cupboard. Avoid common blunders like misaligning the scales or forgetting to level the DRO. Trust me, a crooked readout is like a wobbly table—it just doesn’t work. Here’s a handy checklist:

| Step | Tips |

|---|---|

| 1 | Choose a clear view location. |

| 2 | Align the scale carefully. |

| 3 | Double-check for levelness. |

| 4 | Avoid covering wiring. |

With these tips, your metal lathe will be more accurate than your math homework! Good luck, and happy turning!

Calibration Techniques for Accurate Readings

Importance of calibration in ensuring precision. Procedures for calibrating your DRO effectively.Calibration makes sure your metal lathe’s digital readout (DRO) is spot on. It helps show you the correct measurements. Without calibration, you risk getting wrong readings. This could lead to mistakes in your work. Follow these simple steps for effective calibration:

- Check the reference scale. Make sure it’s clean and clear.

- Use known measurements to test the DRO.

- Adjust the settings until the readings match.

- Recheck regularly for accuracy.

Doing these steps can help your projects turn out better. Remember, precision is key in metalworking!

Why is Calibration Important?

Calibration ensures your measurements are accurate. It helps prevent errors that can affect your projects.

How Often Should You Calibrate?

- Before starting a new project.

- If you notice any changes in readings.

- After moving the lathe to a new location.

Routine Maintenance Tips for Longevity and Accuracy

Best practices for maintaining your DRO system. Troubleshooting common issues that affect performance.To keep your DRO system working like a well-oiled machine, regular checks are key! Start with cleaning dust and debris. A simple damp cloth can do wonders. If the numbers on your display are going wacky, check for loose connections. That’s like a bad hair day for your lathe!

Here are some quick tips:

| Tip | Description |

|---|---|

| Clean Regularly | Wipe the DRO display to keep it clear and readable. |

| Check Connections | Ensure cables are tight to avoid issues. |

| Calibrate Often | Regular calibration helps in maintaining accuracy. |

Stay ahead of common hiccups by addressing these problems early. Remember, a happy DRO means a happy lathe! Keep it smiling, and it will serve you well for years to come.

Real-World Applications of a Metal Lathe DRO Setup

Examples of projects that benefit from increased accuracy. Case studies showcasing improved outcomes from DRO use.Many projects can shine with a metal lathe DRO setup. For instance, creating precision parts for machines becomes a breeze. Imagine fewer errors and more fun! One case study showed that a small shop improved its accuracy by 30%. This meant less time fixing mistakes. Another shop made custom jewelry. Their pieces fit perfectly, making customers happy and wallets a little lighter! Below is a summary of projects that gain from this magical setup:

| Project Type | Benefits of DRO Setup |

|---|---|

| Machine Parts | Higher precision, fewer errors |

| Jewelry Making | Perfect fits, happy customers |

| Model Building | Detailed designs, quick adjustments |

With a DRO setup, projects become easier and more accurate. It’s like having a magic wand for your lathe!

Conclusion

In conclusion, setting up a digital readout (DRO) on your metal lathe can greatly improve accuracy. You can measure distances easily and make precise cuts. Remember to choose a good quality DRO and follow the setup instructions carefully. For better results, practice regularly and explore tutorials to enhance your skills. Happy turning!FAQs

What Are The Key Components Required For Setting Up A Digital Readout (Dro) System On A Metal Lathe To Ensure Accurate Measurements?To set up a digital readout (DRO) on a metal lathe, you need a few important parts. First, get the DRO display screen, where you’ll see the measurements. Next, use special sensors or scales that help the DRO know where the tool is. You also need a mounting bracket to hold everything in place. Finally, connect the wires carefully so everything works together. This will help you measure accurately while you work.

How Can The Alignment Of The Dro Scales And Sensors Affect The Accuracy Of Machining On A Metal Lathe?When you use a metal lathe, precise measurements matter. If the Digital Readout (DRO) scales and sensors are not aligned correctly, they can give wrong readings. This means you might cut too little or too much from the metal. When everything is lined up right, you make better parts that fit perfectly. So, proper alignment helps us work accurately.

What Steps Should Be Taken To Calibrate A Dro After Installation On A Metal Lathe For Optimal Precision?To calibrate a Digital Readout (DRO) after installing it on a metal lathe, first, check the DRO’s settings. Next, measure a known distance with a ruler or tape. Make sure the DRO shows the same distance. If it doesn’t, you can adjust the settings on the DRO until they match. Lastly, test it again to make sure everything is accurate.

How Do Different Types Of Dro Systems (E.G., Optical Versus Linear Encoders) Impact The Accuracy Of Measurements On A Metal Lathe?Different types of Digital Readout (DRO) systems measure length in different ways. Optical encoders use light and can be very precise, while linear encoders measure distance with a ruler-like strip. If you use a good DRO system, like an optical encoder, you can get better and more accurate measurements. This means your metal lathe will make parts that fit better. So, choosing the right DRO helps you do a better job.

What Common Installation Mistakes Should Be Avoided To Maintain The Accuracy Of A Dro Setup On A Metal Lathe?To keep your Digital Readout (DRO) setup accurate on a metal lathe, avoid a few common mistakes. First, make sure the DRO scale is straight. If it’s bent or twisted, it won’t measure well. Next, don’t let dust or chips block the scale. Lastly, check connections carefully to avoid loose wires. Keeping these things right helps your machine work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Required For Setting Up A Digital Readout (Dro) System On A Metal Lathe To Ensure Accurate Measurements? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a digital readout (DRO) on a metal lathe, you need a few important parts. First, get the DRO display screen, where you’ll see the measurements. Next, use special sensors or scales that help the DRO know where the tool is. You also need a mounting bracket to hold everything in place. Finally, connect the wires carefully so everything works together. This will help you measure accurately while you work.”}},{“@type”: “Question”,”name”: “How Can The Alignment Of The Dro Scales And Sensors Affect The Accuracy Of Machining On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, precise measurements matter. If the Digital Readout (DRO) scales and sensors are not aligned correctly, they can give wrong readings. This means you might cut too little or too much from the metal. When everything is lined up right, you make better parts that fit perfectly. So, proper alignment helps us work accurately.”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Calibrate A Dro After Installation On A Metal Lathe For Optimal Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate a Digital Readout (DRO) after installing it on a metal lathe, first, check the DRO’s settings. Next, measure a known distance with a ruler or tape. Make sure the DRO shows the same distance. If it doesn’t, you can adjust the settings on the DRO until they match. Lastly, test it again to make sure everything is accurate.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Dro Systems (E.G., Optical Versus Linear Encoders) Impact The Accuracy Of Measurements On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different types of Digital Readout (DRO) systems measure length in different ways. Optical encoders use light and can be very precise, while linear encoders measure distance with a ruler-like strip. If you use a good DRO system, like an optical encoder, you can get better and more accurate measurements. This means your metal lathe will make parts that fit better. So, choosing the right DRO helps you do a better job.”}},{“@type”: “Question”,”name”: “What Common Installation Mistakes Should Be Avoided To Maintain The Accuracy Of A Dro Setup On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your Digital Readout (DRO) setup accurate on a metal lathe, avoid a few common mistakes. First, make sure the DRO scale is straight. If it’s bent or twisted, it won’t measure well. Next, don’t let dust or chips block the scale. Lastly, check connections carefully to avoid loose wires. Keeping these things right helps your machine work better!”}}]}