Have you ever needed a part that just isn’t available in stores? It happens all the time. You might need a special bushing for a project. A metal lathe for making custom bushings can solve that problem. This powerful machine lets you create precise parts right at home.

Imagine you have an old bicycle. The pedal is loose because the bushing is worn out. Instead of searching for a replacement, wouldn’t it be great to make your own? With a metal lathe, you can do just that!

Many hobbyists and DIY enthusiasts use metal lathes to craft parts. They enjoy turning raw metal into useful tools or pieces. Did you know that people have been using lathes for thousands of years? It’s true! This ancient tool helps bring ideas to life.

In this article, we will explore how the metal lathe works. We will also share tips for making your own custom bushings. Get ready to unlock your creativity and tackle your next project with confidence!

Metal Lathe For Making Custom Bushings: A Guide To Precision Introduction In The World Of Machining, A Metal Lathe Is An Essential Tool For Fabricating Custom Components, Including Bushings. These Versatile Machines Allow For Precise Shaping And Cutting Of Metals, Making It Possible To Create Custom Bushings Tailored For Various Applications. Whether You’Re Crafting A Unique Part For A Personal Project Or A Component For Industrial Use, Understanding The Capabilities Of A Metal Lathe Is Crucial. What Is A Metal Lathe? A Metal Lathe Is A Machine Tool Used To Shape Metal By Removing Material Through A Rotating Workpiece. It Operates By Holding The Metal Securely In Place With A Chuck, While Different Cutting Tools Are Used To Achieve The Desired Shape And Dimensions. The Lathe’S Ability To Rotate The Workpiece At Various Speeds And The Use Of Precise Tools Make It An Indispensable Asset For Any Machining Workshop. Importance Of Custom Bushings Bushings Are Critical Components In Mechanical Assemblies, Acting As Bearings Or Spacers. Custom Bushings Can Be Designed To Fit Specific Dimensions And Requirements, Ensuring Optimal Performance And Longevity. With A Metal Lathe, You Can Create Bushings That Not Only Fit Perfectly But Also Enhance The Efficiency Of Machinery And Equipment. Key Features Of Metal Lathes For Custom Bushings When Selecting A Metal Lathe For Making Custom Bushings, Several Key Features Must Be Considered: – **Precision Control**: Look For Lathes With Digital Readouts For Accurate Measurements. – **Tool Variety**: The Ability To Use Different Cutting Tools Allows For Complex Designs. – **Speed Settings**: Adjustable Speeds Help In Working With Various Metals And Thicknesses. – **Durability**: A Robust Construction Will Ensure Longevity And Reliability During Heavy Usage. Steps To Make Custom Bushings Using A Metal Lathe 1. **Design The Bushing**: Create A Detailed Design With Precise Measurements. 2. **Select The Material**: Choose The Right Metal, Considering Factors Like Strength And Corrosion Resistance. 3. **Set Up The Lathe**: Properly Secure The Material In The Lathe And Select The Appropriate Cutting Tools. 4. **Turn The Material**: Begin The Turning Process, Making Gradual Cuts To Achieve The Desired Shape. 5. **Finishing Touches**: Sand And Polish The Bushings To Remove Sharp Edges And Ensure A Smooth Finish. Conclusion A Metal Lathe For Making Custom Bushings Can Significantly Enhance Your Machining Capabilities. With Its Accuracy And Versatility, You Can Produce High-Quality, Custom Parts That Meet Specific Requirements. Whether You’Re An Enthusiast Or A Professional Machinist, Investing In A Good Quality Metal Lathe Will Open Up New Possibilities In Your Custom Fabrication Projects.

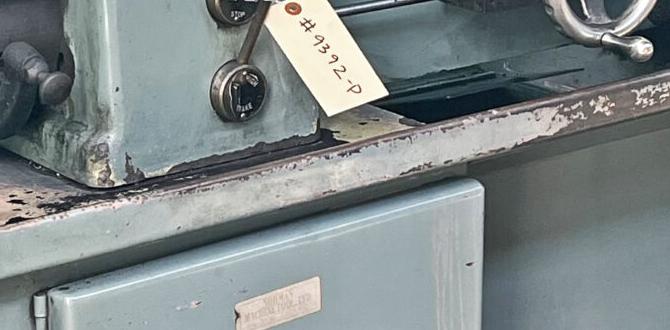

Metal Lathe for Making Custom Bushings

Using a metal lathe to create custom bushings can be exciting and rewarding. These machines let you shape metal into exact forms needed for projects. Did you know that precision in bushings can improve how machines work? A good metal lathe allows you to craft parts that fit perfectly, reducing damage and wear. Whether you’re a hobbyist or a pro, understanding this tool can open doors to endless creative possibilities. Why not give it a try?Understanding Metal Lathes

Definition and purpose of metal lathes. Types of metal lathes available in the market.Metals lathes are machines that shape and cut metal into exact sizes. Think of them as the artists’ tools for metal! Their main purpose is to turn metal pieces into custom shapes, like bushings. There are different types of metal lathes. Each type serves unique needs, from small hobbyist machines to larger industrial ones. Here’s a quick look:

| Type of Lathe | Ideal Use |

|---|---|

| Benchtop Lathe | Home projects and small parts |

| Toolroom Lathe | Precision work and intricate designs |

| Production Lathe | Mass-producing parts |

With the right lathe, anyone can become a metal wizard! So gather your tools and get ready to spin your creativity into reality.

Choosing the Right Metal Lathe for Custom Bushings

Key features to consider (size, power, precision). Comparison of top brands and models.Finding the perfect metal lathe for making custom bushings can be a bit tricky, like trying to pick your favorite candy at a candy store. You’ll want to check a few key features first: size, power, and precision. The size needs to fit your workspace, while the power comes from the motor. Precision is key, so your bushings fit like a glove!

Some top brands offer reliable choices. Here’s a quick comparison:

| Brand | Size (inches) | Power (HP) | Precision (mm) |

|---|---|---|---|

| Brand A | 12 | 1.5 | 0.01 |

| Brand B | 10 | 2.0 | 0.02 |

| Brand C | 14 | 1.0 | 0.005 |

Each brand has something special, and you might want to listen to what your friends at the workshop say too. They often know which models do the trick without blowing your budget!

Essential Tools and Accessories for Lathe Operations

Musthave tools for making custom bushings. Optional accessories to enhance functionality.Creating custom bushings is easier with the right tools. First, you need a high-quality lathe. It cuts metal accurately. Next, don’t forget the tool rest and cutting tools. They help you shape the metal perfectly. Looking for extras? Consider a digital readout system for precise measurements. Need a laugh? A good wrench can sometimes be your best friend—it’s not just a tool; it’s an essential therapist for those stubborn bolts!

| Must-Have Tools | Optional Accessories |

|---|---|

| Lathe | Digital Readout |

| Cutting Tools | Chucks |

| Tool Rest | Faceplates |

Step-by-Step Process for Making Custom Bushings

Preparatory steps before starting the lathe. Detailed process of turning a bushing on a metal lathe.Before using a metal lathe to make custom bushings, there are a few important steps. First, gather your materials, including metal rod and tools. Next, measure and mark your metal piece. Be sure to wear safety gear like goggles. Once you’re prepared, follow these steps:

- Secure the workpiece in the lathe.

- Select the right cutting tool.

- Adjust speed to match the metal type.

- Start the machine and slowly feed the tool into the metal.

- Check the bushing often to ensure proper fitting.

This careful process helps make strong and accurate custom bushings. Enjoy creating!

How to start a metal lathe safely?

Always wear safety goggles and keep hands clear of moving parts. Read the machine manual before starting, and make sure the workspace is clean.

Common Mistakes and Troubleshooting Tips

Frequent errors in bushing production. Solutions for common latherelated problems.Making custom bushings can be tricky. Common problems include incorrect measurements and using dull tools. Measure twice, cut once—wise words from every dad! If your bushing doesn’t fit, check your specs. Use a metal lathe with the right speed and feed rate. If things get squeaky, it might be time for new tools. Here’s a handy table with errors and fixes:

| Error | Solution |

|---|---|

| Incorrect dimensions | Double-check measurements |

| Dull cutting tools | Replace or sharpen tools |

| Excessive noise | Lubricate parts |

Staying alert to these issues can save you time and effort. Keep laughing through the bumps, and your custom bushings will turn out great!

Safety Practices When Using a Metal Lathe

Essential safety gear and practices. Tips for maintaining a safe workspace.Always gear up before using a metal lathe. Safety glasses and ear protection are must-haves. You don’t want to lose an eye or your hearing while making custom bushings! Keep your workspace tidy. A cluttered space is like inviting trouble for a dance party. Be sure to keep tools in their rightful places. Don’t rush; your highest speed should be checking your safety gear, not the lathe!

| Essential Safety Gear | Safe Practices |

|---|---|

| Safety glasses | Keep workspace clean |

| Ear protection | Use tools properly |

| Gloves | Don’t rush! |

Applications of Custom Bushings

Industries that benefit from custom bushings. Realworld examples of bushing applications.Many industries rely on custom bushings for their machines. From automotive to manufacturing, these parts help machines run smoothly. For example, custom bushings can be found in:

- Cars: They reduce friction in engines.

- Construction: Heavy equipment uses bushings for stability.

- Aerospace: They help parts move without wear.

By using metal lathes, businesses create the exact bushings they need. This leads to better performance and longer-lasting tools.

What are some industries that use custom bushings?

Industries like automotive, aerospace, and manufacturing benefit greatly from custom bushings. They improve machine performance and extend the life of equipment.

Maintenance and Care for Metal Lathes

Routine maintenance tasks for optimal performance. Signs that indicate the need for repairs or adjustments.Keeping your metal lathe in tip-top shape is easier than finding a spare sock in the laundry! Regular tasks like cleaning, oiling, and checking belts help it run smoothly. Catching signs of troubles, like strange noises or wobbly parts, ensures your lathe stays happy. Don’t let it feel neglected, or it might start throwing temper tantrums—and you don’t want that!

| Maintenance Task | Frequency |

|---|---|

| Clean the lathe | Daily |

| Oil moving parts | Weekly |

| Check the belts | Monthly |

| Inspect for damage | Every 3 months |

Look out for signs that scream “repair me!” If the machine vibrates, makes weird sounds, or parts are loose, it’s time for some TLC. Remember, a well-cared lathe makes making those custom bushings a breeze!

Conclusion

In conclusion, a metal lathe is essential for making custom bushings. It helps you create precise shapes and sizes. Understanding how to use this tool opens up many possibilities for DIY projects. We encourage you to explore tutorials and practice with your lathe. With time and effort, you’ll master making bushings and enhance your skills even further!FAQs

What Are The Essential Features To Look For In A Metal Lathe When Making Custom Bushings?When choosing a metal lathe for making custom bushings, you want a few important features. First, look for a small enough size so you can easily control it. Next, a good motor that runs smoothly helps you work faster. Also, having a sturdy frame keeps the lathe steady while you work. Finally, tools and accessories that fit well make it easier to create the perfect bushing.

How Do You Select The Right Material For Custom Bushings When Using A Metal Lathe?To pick the right material for custom bushings, first think about where you will use them. If they need to resist heat, choose metal. For softer uses, like in machines, plastic might work better. Always consider how strong and durable you need the bushing to be. Last, make sure it’s easy to shape with your metal lathe.

What Are The Typical Machining Processes Involved In Creating Bushings On A Metal Lathe?To make bushings on a metal lathe, we start by cutting the metal piece into a cylinder shape. Then, we drill a hole in the center of the cylinder. Next, we smooth out the outside edges to make it nice and round. Finally, we can polish it to make it shiny. Each step helps create a strong and useful bushing!

How Do You Ensure Precise Measurements And Tolerances When Machining Bushings On A Metal Lathe?To make sure your bushings fit just right, you start by measuring carefully. Use a ruler or caliper to check sizes before you cut. Next, set the metal lathe (a machine that shapes metal) to the right speed and depth. Keep checking the size as you work to make sure it’s perfect. Lastly, always double-check your work with your measuring tools.

What Safety Precautions Should Be Taken While Operating A Metal Lathe For Bushing Fabrication?When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair and clothes away from the machine. Use gloves if you need to, but be careful not to get them caught. Make sure the area is clean and free of clutter. Finally, always follow the machine’s instructions to stay safe.