Have you ever watched a metal lathe in action? It’s like magic! A spinning piece of metal transforms into beautiful shapes right before your eyes. But what makes this process so smooth? One answer lies in the gear train adjustment.

Many people don’t realize how important the gear train is. It controls speed and precision. Without proper adjustment, even the best lathe can struggle. Imagine trying to bake a cake without the right oven settings. It just wouldn’t work!

In this article, we’ll explore how to adjust the metal lathe gear train. You’ll learn simple steps to improve your machining skills. Whether you’re a beginner or have some experience, this guide will help you. So, are you ready to dive into the fascinating world of metal lathes? Let’s get started!

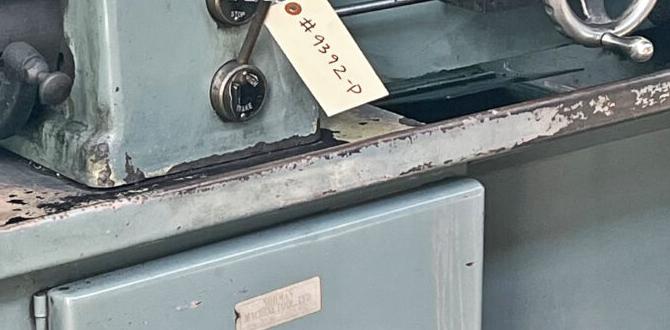

Metal Lathe Gear Train Adjustment: A Complete Guide

Metal Lathe Gear Train Adjustment

Adjusting the gear train on a metal lathe is crucial for smooth operation. Proper adjustments ensure the lathe runs efficiently and creates precise cuts. Users learn how to identify common signs of misalignment and the tools needed for adjustments. Did you know that even a small tweak can improve machining speed? Regular maintenance of the gear train not only increases the life of the lathe but also enhances the quality of work produced.Understanding the Gear Train in Metal Lathes

Explanation of what a gear train is in the context of metal lathes. Importance of gear train for machining accuracy and efficiency.A gear train is a series of gears working together in a metal lathe. Each gear helps turn the machine smoothly. This system is important for getting precise cuts in metal. It makes the lathe work efficiently. Without a proper gear train, mistakes can happen. These mistakes can lead to wasted materials and time.

- Gears change speed and torque.

- They help control the movement accurately.

- The gear train improves overall machine performance.

Why is the gear train important for a metal lathe?

The gear train ensures accuracy in machining. It also boosts efficiency, saving both time and resources. Accurate cuts lead to better quality products.

Tools and Equipment Required for Adjustment

List of essential tools for gear train adjustments. Safety equipment and precautions to consider.For a successful gear train adjustment, you’ll need a few handy tools. First, grab a wrench set for bolts, along with screwdrivers for those tricky screws. Don’t forget a caliper to measure parts accurately. Safety goggles are a must—metal shavings and tiny accidents don’t mix well with eyes! And of course, a sturdy workbench is essential; no one likes chasing tools across the floor.

| Tool | Purpose |

|---|---|

| Wrench Set | For turning bolts |

| Screwdrivers | To adjust screws |

| Caliper | For accurate measurements |

| Safety Goggles | To protect your eyes |

| Workbench | Stable work area |

Before you start, remember: safety first! Always wear those goggles, and watch your fingers. A well-prepared workspace keeps accidents at bay. Happy adjusting!

Step-by-Step Guide to Adjusting the Gear Train

Detailed instructions for adjusting the gear train. Tips for maintaining accuracy during the adjustment process.Adjusting the gear train can be as fun as a puzzle game. First, locate the adjustment screw on your machine. This will be your trusty sidekick during the process. Turn it gently, watching the gears move. If it feels too tight, loosen it a bit. It’s like making sure your shoelaces aren’t too tight! Follow this handy table for quick reference:

| Step | Action |

|---|---|

| 1 | Locate adjustment screw |

| 2 | Gently turn to adjust |

| 3 | Check for smooth movement |

For accuracy, keep checking each adjustment. It’s like balancing a stack of pancakes—too wobbly, and it all falls down. Remember, patience pays off. Who knew adjusting a gear train could be such a work of art?

Fine-Tuning the Gear Train for Optimal Performance

Techniques for finetuning after the initial adjustments. How to test the lathe’s performance postadjustment.After adjusting your lathe, it’s time for some finetuning. This step ensures your machine runs smoothly. Use the following techniques for best results:

- Check gear alignment: Make sure all gears mesh well.

- Adjust tension: Ensure the belts are tight but not too tight.

- Monitor noise: Listen for any unusual sounds during operation.

After making adjustments, test the lathe’s performance. You can do this by:

- Running a simple cut: This shows how well the lathe works.

- Measuring the output: Check the precision of your cut.

This finetuning helps achieve optimal performance. Happy lathe-ing!

How do I know if my lathe is performing well?

To check performance, run a test cut and measure the result. If your cut is even and smooth, it likely means the lathe is working well. Keep an ear out for any strange noises!

Preventative Maintenance for Gear Train Longevity

Recommended maintenance practices to prolong gear train life. Frequency of checks and adjustments needed.Taking care of your gear train is like feeding a pet—ignore it, and things can get messy! Regular checks can help keep it running smoothly. It’s best to make these checks every month. Look for wear and tear, and make adjustments as needed. Think of it as a little tune-up for your machine dance party. Here’s a handy table for your maintenance schedule:

| Maintenance Task | Frequency |

|---|---|

| Inspect Gears | Monthly |

| Clean Lubrication | Every 3 Months |

| Check Alignments | Every 6 Months |

By sticking to this routine, you’ll help your gear train last longer, avoid sudden breakdowns, and keep your projects going. Remember, a happy gear train is a productive gear train!

Troubleshooting Common Gear Train Problems

Solutions for issues that may arise during or after adjustments. How to diagnose issues effectively.Gear trains can sometimes act like stubborn mules after adjustments. It’s important to address common issues right away. First, check that all gears are properly aligned. Misalignment can cause odd noises and poor performance. If the gears are stuck, they might need a little lubrication. A squeaky wheel is funny in cartoons, but not on your lathe! And if you’re facing slippage, adjusting the tension might just do the trick. Remember, a little troubleshooting goes a long way!

| Problem | Solution |

|---|---|

| Misalignment | Realign the gears |

| Sticking gears | Lubricate the system |

| Slippage | Adjust the tension |

FAQs about Metal Lathe Gear Train Adjustments

Answers to commonly asked questions on gear train adjustments. Clarification on misconceptions regarding lathe operation and maintenance.Many folks have questions about adjusting the gear train on a metal lathe. Common queries include how often to make these adjustments and the effects of improper settings. Don’t worry; you’re not alone! It’s important to know that adjustments should be made based on wear and tear, rather than just on a schedule. Misunderstandings often arise about how lathe maintenance works. Regular checks can save you from big headaches and long repair waits. Think of it like giving your lathe a health check-up!

| Common Questions | Answers |

|---|---|

| How often should I adjust the gear train? | Whenever it starts to act weird! |

| Can I skip adjustments? | Only if you enjoy surprises! |

| Is it hard to make adjustments? | Not if you follow the manual! |

Conclusion

In conclusion, adjusting the gear train on a metal lathe is important for smooth operation. You learned how gear adjustments affect speed and power. Always check the manufacturer’s guide for specific tips. Regular maintenance helps prevent issues. Explore online resources or manuals to deepen your understanding. With practice, you’ll be able to master your lathe adjustments confidently!FAQs

What Are The Common Signs That Indicate A Gear Train Adjustment Is Needed On A Metal Lathe?If you hear unusual noises coming from the lathe, it might need an adjustment. You might also see vibrations or shaking while it’s working. If the cutting speed feels uneven or too slow, that’s another sign. Finally, if the tool isn’t cutting straight, it’s time to check the gear train. These signals show us that something needs fixing.

How Do You Properly Calculate The Gear Ratios For Specific Spindle Speeds In A Metal Lathe’S Gear Train?To calculate gear ratios for your metal lathe, you need to know the size of each gear. First, count the number of teeth on the driving gear. Then, count the teeth on the driven gear. You divide the number of teeth on the driven gear by the number of teeth on the driving gear. This gives you the gear ratio. Finally, multiply this ratio by the spindle speed to find the new speed you want.

What Tools And Materials Are Required For Adjusting The Gear Train On A Metal Lathe?To adjust the gear train on a metal lathe, you need a few tools. First, grab a wrench to tighten or loosen bolts. You will also need a screwdriver to adjust small screws. A ruler helps you measure things correctly. Finally, having some clean cloths nearby is good for wiping up any oil.

How Do You Disassemble And Reassemble The Gear Train Components Safely During The Adjustment Process?To take apart the gear train, first, you should turn off the machine and unplug it for safety. Next, carefully remove any screws holding the parts together. Keep track of all the small pieces in a container so they don’t get lost. When reassembling, start by putting the biggest part back in place. Then, add the smaller pieces and tighten the screws. Always double-check your work before turning the machine back on.

What Are The Potential Consequences Of Improper Gear Train Adjustments On A Metal Lathe’S Performance And Accuracy?If we don’t adjust the gear train on a metal lathe properly, it can cause problems. The lathe might make wobbly or uneven cuts. This means our projects won’t look good or fit together well. It can also wear out the machine faster, which costs more money to fix. Taking time to adjust it right helps us make better work and keep our lathe happy!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Gear Train Adjustment Is Needed On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you hear unusual noises coming from the lathe, it might need an adjustment. You might also see vibrations or shaking while it’s working. If the cutting speed feels uneven or too slow, that’s another sign. Finally, if the tool isn’t cutting straight, it’s time to check the gear train. These signals show us that something needs fixing.”}},{“@type”: “Question”,”name”: “How Do You Properly Calculate The Gear Ratios For Specific Spindle Speeds In A Metal Lathe’S Gear Train? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate gear ratios for your metal lathe, you need to know the size of each gear. First, count the number of teeth on the driving gear. Then, count the teeth on the driven gear. You divide the number of teeth on the driven gear by the number of teeth on the driving gear. This gives you the gear ratio. Finally, multiply this ratio by the spindle speed to find the new speed you want.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Required For Adjusting The Gear Train On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the gear train on a metal lathe, you need a few tools. First, grab a wrench to tighten or loosen bolts. You will also need a screwdriver to adjust small screws. A ruler helps you measure things correctly. Finally, having some clean cloths nearby is good for wiping up any oil.”}},{“@type”: “Question”,”name”: “How Do You Disassemble And Reassemble The Gear Train Components Safely During The Adjustment Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take apart the gear train, first, you should turn off the machine and unplug it for safety. Next, carefully remove any screws holding the parts together. Keep track of all the small pieces in a container so they don’t get lost. When reassembling, start by putting the biggest part back in place. Then, add the smaller pieces and tighten the screws. Always double-check your work before turning the machine back on.”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Improper Gear Train Adjustments On A Metal Lathe’S Performance And Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If we don’t adjust the gear train on a metal lathe properly, it can cause problems. The lathe might make wobbly or uneven cuts. This means our projects won’t look good or fit together well. It can also wear out the machine faster, which costs more money to fix. Taking time to adjust it right helps us make better work and keep our lathe happy!”}}]}