Have you ever faced the frustrating problem of chatter when using a metal lathe? You’re not alone. Many hobbyists and professionals encounter this issue while parting off material. Chatter can ruin your work, leading to mistakes and wasted time.

Imagine you’re deep into a project. You’ve measured every piece carefully. Suddenly, that annoying vibration starts. It can make you feel defeated. But what if there’s a way to fix it?

Let’s explore easy tips and tricks to reduce or even eliminate metal lathe parting blade chatter. You’ll learn about the best tools and techniques to help you maintain a smooth cut. With the right knowledge, you can achieve perfect results, turning frustration into satisfaction.

Ready to dive in? Let’s get started on fixing that chatter once and for all!

Metal Lathe Parting Blade Chatter Fix: Effective Solutions

Metal Lathe Parting Blade Chatter Fix

Parting blades can create annoying chatter when working on metal lathes. This can lead to poor cuts and frustration. Understanding the causes of chatter is essential. Factors like feed rate and tool sharpness play vital roles. Adjusting these settings can significantly improve your results. Did you know that even a small change in blade angle can reduce chatter? Experimenting with different techniques makes the process easier. With the right adjustments, you can achieve smoother, cleaner cuts every time!Understanding Chatter in Metal Lathing

Definition of chatter and its impact on machining quality. Common causes of chatter in metal lathes.Chatter is like the unwelcome dance partner in metal lathing—it shakes things up in a bad way! This annoying vibration can ruin your machining quality, leaving you with rough and uneven surfaces. Common causes include too much speed, dull tools, or a weak setup. Avoid these like you avoid stepping on gum on the sidewalk!

| Cause of Chatter | Description |

|---|---|

| Excessive Speed | Too fast? It makes the tool jiggle! |

| Dull Tools | Like cutting with a butter knife—no good! |

| Poor Setup | If it’s wobbly, so will your cut! |

By understanding chatter and its triggers, you can steer clear of these pitfalls and keep your machining smooth and efficient—like a well-oiled machine!

Identifying Signs of Chatter

Visual indicators of chatter in finished parts. How vibration affects tool wear and workpiece integrity.When using a metal lathe, look for signs of chatter in your finished parts. Surface marks can appear as grooves or uneven spots on the metal. These marks happen if the tool vibrates during cutting. This vibration causes tool wear and can affect how strong the part is.

- Rough edges may indicate chatter.

- Patterns or waves on the surface show irregularities.

- Uneven thickness can mean the tool is bouncing.

What are common signs of chatter in machining?

Common signs include rough surfaces, visible grooves, and uneven thickness. These can affect the quality of the part.

Key Factors Contributing to Chatter

Tooling selection: parting blades vs. traditional tools. Machine settings: speed, feed rate, and depth of cut.Chatter can be a pesky problem for any metal lathe enthusiast. First, let’s chat about tooling. Using parting blades can make a big difference compared to regular tools. They tend to offer better control, keeping things smooth and steady. Next, consider machine settings. The right speed, feed rate, and depth of cut are essential. Too high or too low can lead to unwanted vibrations. It’s like trying to dance on a wobbly table—nobody wants that!

| Factor | Effect on Chatter |

|---|---|

| Tool Selection | Parting blades reduce vibrations. |

| Speed | High speeds may increase chatter. |

| Feed Rate | Too fast can result in wobbling. |

| Depth of Cut | Shallower cuts are smoother. |

Adjusting Tooling and Setup

Proper mounting techniques for parting blades. Using a solid setup to stabilize the workpiece.Mounting parting blades correctly is key to a smooth operation. First, make sure they sit snugly in the tool holder. A loose blade can cause chatter—like when your friend hums off-beat. Next, check your workpiece. It needs a solid grip! Picture trying to cut a piece of jelly with a butter knife; it just won’t work. Stable setups help keep the blade’s path clear and chatter-free.

| Tip | Description |

|---|---|

| Mounting | Ensure the blade is tight and securely fastened. |

| Stability | Use vices to hold the workpiece firmly. |

By focusing on these simple steps, you’ll be on your way to parting like a pro, minus the prattle. Remember, a happy lathe is a productive lathe!

Optimizing Machine Parameters

Recommendations for appropriate speeds and feeds. Importance of maintaining uniform cutting depth.Getting your machine settings right is key to a smooth operation. First, choose the right speeds and feeds for your metal lathe. Too fast, and it’s like trying to outrun a cheetah on a tricycle. Too slow, and you might as well be watching paint dry. Here’s a quick guide:

| Material | Speed (RPM) | Feed Rate (IPR) |

|---|---|---|

| Aluminum | 600-1200 | 0.005-0.03 |

| Steel | 200-600 | 0.001-0.01 |

| Brass | 300-800 | 0.005-0.04 |

Next, keep a consistent cutting depth. Imagine trying to cut a cake with a wobbly knife. It won’t end well! A uniform depth ensures smooth cuts and less vibration, reducing chatter and keeping your blade happy. Follow these tips, and you’ll be the master of your metal lathe in no time!

Application of Cutting Fluid

Benefits of using cutting fluid to minimize chatter. Types of cutting oils and their effectiveness.Using cutting fluid can help reduce chatter when using a metal lathe. Chatter can cause poor cuts, ruining your work. A good cutting fluid cools the tool and helps it glide smoothly. This makes your cuts cleaner and faster.

- Mineral Oil: Great for its cooling ability.

- Synthetic Oil: Lasts longer and works well under stress.

- Water-Soluble Oils: Easy to clean and less messy.

Each type of cutting oil has its own benefits. Choose one based on your project for the best results!

What are the benefits of cutting fluid?

Cutting fluid reduces heat, improves tool life, and creates better finishes. It’s important for smooth operation.

Benefits of Cutting Fluid

- Keeps tools cool.

- Provides lubrication.

- Reduces wear on tools.

Advanced Techniques for Reducing Chatter

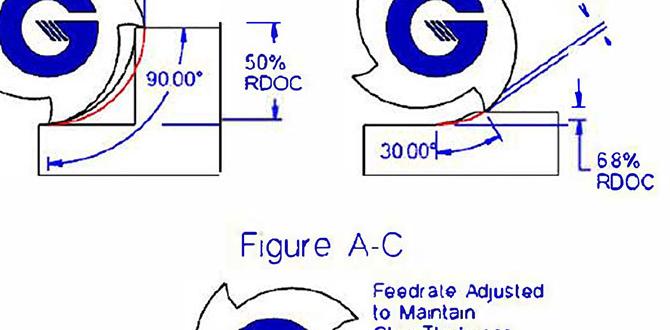

Use of dampening tools and accessories. Exploring different parting blade geometries.Chatter in metal lathes can be a real party crasher, but there are fun ways to fix it. First, using dampening tools helps absorb vibrations. Think of it as putting a pillow on a bumpy ride! Next, explore different parting blade geometries. Some shapes work better than others, like choosing between pizza slices or cake slices. With the right tools and blade shape, you can smooth out those rough edges and enjoy a quieter cutting experience.

| Technique | Benefit |

|---|---|

| Dampening Tools | Reduces vibrations |

| Different Blade Geometries | Improves cutting efficiency |

Routine Maintenance to Prevent Chatter

Importance of regular inspection and maintenance of lathe components. Best practices for keeping lathe and tooling in optimal condition.Regular checks and upkeep of your lathe are key to smooth operations. This helps prevent issues like chatter. A well-maintained lathe lasts longer and works better. Here are some best practices:

- Check belts and bearings often.

- Keep the lathe clean and free of debris.

- Inspect tooling for sharpness and wear.

- Lubricate moving parts regularly.

These steps may seem small, but they make a big difference in performance!

How can I ensure my lathe runs smoothly?

Regular inspections and cleaning help keep your lathe running smoothly. Routine maintenance reduces wear and tear, which can lead to chatter. Paying attention to your machine often saves time and money in the long run.

Conclusion

To fix metal lathe parting blade chatter, adjust the tool’s height and reduce the speed. Keep the blade sharp for better cuts. You can also try using cutting oils to improve performance. These steps help create smoother finishes in your projects. For more tips, check out guides on lathe techniques. Happy crafting!FAQs

Here Are Five Related Questions On The Topic Of Fixing Chatter When Using A Parting Blade On A Metal Lathe:Chatter happens when the parting blade vibrates too much. To fix it, make sure the blade is sharp and clean. You can also try changing the speed of the lathe. Using a steady hand can help too. Lastly, adjust how hard you press the blade against the metal.

Sure! Please provide me with the question you want answered, and I’ll be happy to help!

What Are The Common Causes Of Chatter When Using A Parting Blade On A Metal Lathe?Chatter happens when the parting blade shakes while cutting. This can occur if the blade is dull or if it’s not set correctly. If you go too fast or use too much pressure, that can cause problems too. The workpiece might not be held tightly enough, causing it to move. Making sure everything is tight and using a sharp blade can help.

How Can The Speed And Feed Rates Be Adjusted To Minimize Chatter During Parting Operations?To reduce chatter when parting metal, you can change the speed and feed rates. First, try lowering the speed of the cutting tool. This helps the tool cut smoothly without shaking. Next, adjust the feed rate, which is how quickly you move the tool toward the metal, to a slower pace. By doing this, you can help make a cleaner cut and reduce noise.

What Type Of Cutting Oil Or Lubricant Is Most Effective In Reducing Chatter When Parting Metal?To reduce chatter when parting metal, you can use a heavy-duty cutting oil. These oils are thick and help cool the metal. They also make it smoother as you cut. Using this oil can help you get a cleaner cut with less noise. It’s great for keeping everything running smoothly!

Are There Specific Tool Geometry Or Parting Blade Designs That Can Help Reduce Chatter?Yes, certain tool shapes and designs can help reduce chatter. You can use thicker blades for more support. Curved edges can also help in cutting smoothly. The right angle of the tool can cut better, leading to less noise. By picking the right design, you can make your work easier and quieter!

How Can The Lathe’S Setup Or Rigidity Be Improved To Prevent Chatter During Parting?To stop chatter when parting on a lathe, you can make some changes. First, make sure the lathe is really tight and doesn’t wobble. You can add weights or clamps to hold everything in place. Using a sharp cutting tool helps too. Lastly, try to go slower while cutting, which can also help keep things steady.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Fixing Chatter When Using A Parting Blade On A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Chatter happens when the parting blade vibrates too much. To fix it, make sure the blade is sharp and clean. You can also try changing the speed of the lathe. Using a steady hand can help too. Lastly, adjust how hard you press the blade against the metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you want answered, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Common Causes Of Chatter When Using A Parting Blade On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Chatter happens when the parting blade shakes while cutting. This can occur if the blade is dull or if it’s not set correctly. If you go too fast or use too much pressure, that can cause problems too. The workpiece might not be held tightly enough, causing it to move. Making sure everything is tight and using a sharp blade can help.”}},{“@type”: “Question”,”name”: “How Can The Speed And Feed Rates Be Adjusted To Minimize Chatter During Parting Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce chatter when parting metal, you can change the speed and feed rates. First, try lowering the speed of the cutting tool. This helps the tool cut smoothly without shaking. Next, adjust the feed rate, which is how quickly you move the tool toward the metal, to a slower pace. By doing this, you can help make a cleaner cut and reduce noise.”}},{“@type”: “Question”,”name”: “What Type Of Cutting Oil Or Lubricant Is Most Effective In Reducing Chatter When Parting Metal?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce chatter when parting metal, you can use a heavy-duty cutting oil. These oils are thick and help cool the metal. They also make it smoother as you cut. Using this oil can help you get a cleaner cut with less noise. It’s great for keeping everything running smoothly!”}},{“@type”: “Question”,”name”: “Are There Specific Tool Geometry Or Parting Blade Designs That Can Help Reduce Chatter?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, certain tool shapes and designs can help reduce chatter. You can use thicker blades for more support. Curved edges can also help in cutting smoothly. The right angle of the tool can cut better, leading to less noise. By picking the right design, you can make your work easier and quieter!”}},{“@type”: “Question”,”name”: “How Can The Lathe’S Setup Or Rigidity Be Improved To Prevent Chatter During Parting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stop chatter when parting on a lathe, you can make some changes. First, make sure the lathe is really tight and doesn’t wobble. You can add weights or clamps to hold everything in place. Using a sharp cutting tool helps too. Lastly, try to go slower while cutting, which can also help keep things steady.”}}]}