Have you ever faced a problem with your metal lathe? It can be frustrating when something so essential stops working. One common issue is the power feed lever. When this part breaks, it can bring your projects to a halt. But don’t worry! Repairing the metal lathe power feed lever is easier than you might think.

Many DIY enthusiasts have tackled this repair. You may wonder how they did it. Did you know that simple tools and some patience can make a big difference? Imagine getting your metal lathe back in working order in no time.

In this article, we’ll guide you through the steps to fix your power feed lever. You’ll discover tips and tricks that make the process smooth. Who knows? You might impress your friends with your handy skills!

Metal Lathe Power Feed Lever Repair: A Comprehensive Guide

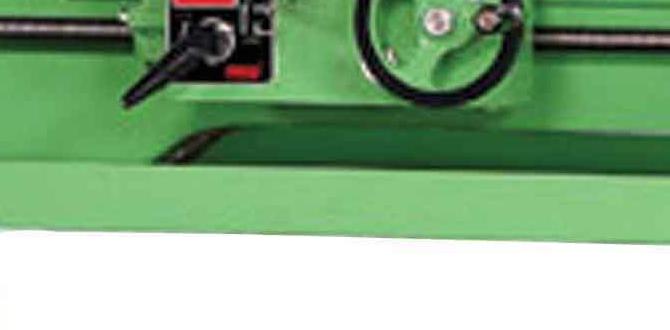

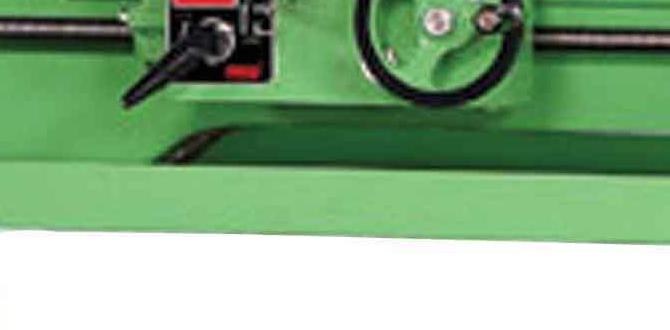

Metal Lathe Power Feed Lever Repair

Fixing a metal lathe’s power feed lever seems tough, right? It can be a simple task if you know the steps. Start by examining the lever for damage. You might just need to tighten loose screws or replace broken parts. Always use the right tools to make your work easier. Did you know that regular checks can extend your lathe’s life? With a little patience, you can keep your lathe running smoothly and efficiently!Understanding the Metal Lathe Power Feed System

Explanation of how a metal lathe power feed system operates. Common components involved in the power feed mechanism.The metal lathe power feed system is like a helpful robot for your lathe! It pushes and pulls materials to create precise shapes. This system makes the machine do the hard work, so you can focus on your masterpiece. Key parts include the feed motor, gears, and switches. Without them, you’d be cranking all day like a human hamster on a wheel!

| Component | Function |

|---|---|

| Feed Motor | Powers the movement of the tool |

| Gears | Control speed and direction |

| Switches | Turn the system on or off |

Each piece plays a role in making sure your work is smooth and accurate, changing your lathe from an ordinary tool into a magical shaping machine!

Step-by-Step Diagnosis of Power Feed Lever Problems

Tools and materials needed for diagnosis. Detailed process for diagnosing power feed lever issues.To check your power feed lever, first gather the right tools. You’ll need a screwdriver, a wrench, and a digital multimeter. Here’s how to diagnose the issues:

- Start by inspecting the lever for any visible damage.

- Use your screwdriver to check for loose screws and tighten them.

- Test the electrical connections with the multimeter to ensure they are working.

Following these steps can help identify the problem effectively. Regular checks can prevent bigger issues down the road.

What tools are essential for diagnosing the power feed lever?

The essential tools include a screwdriver, a wrench, and a digital multimeter.

Disassembling the Power Feed Lever

Precautions and steps for safe disassembly. Key components to inspect during disassembly.Before tackling the power feed lever, safety first! Wear gloves and goggles; you don’t want any surprises, like a spring flying off like a confetti cannon. Start by gently removing screws—don’t drop them; they can be as slippery as a banana peel. As you disassemble, keep an eye out for key parts like the lever itself and any springs. They’re as important as pizza toppings!

| Component | Inspection Tips |

|---|---|

| Power Feed Lever | Check for cracks or wear. |

| Springs | Look for rust or deformation. |

| Screws | Make sure they aren’t stripped. |

Repairing the Power Feed Lever

Techniques for fixing common lever issues. Tips for replacing worn or damaged parts.Fixing the power feed lever can be easy. First, check for any loose screws or broken springs. Tightening or replacing these parts can resolve many problems. If parts are worn out, they may need replacement. Here are some tips:

- Inspect the lever for cracks or wear.

- Replace damaged springs with new ones.

- Use tools carefully to avoid causing more issues.

- Regular maintenance can prevent future problems.

With these techniques, you can keep your lathe working smoothly!

What are common power feed lever issues?

Common issues include worn-out springs, loose screws, and cracks in the lever. Regularly checking these parts can help you catch problems early.

Reassembling the Power Feed Lever

Stepbystep guide to reassemble after repairs. Ensuring proper alignment and functionality upon reassembly.After fixing the power feed lever, reassembly is key. Follow these steps for best results:

- Start with the main body. Ensure it’s clean and free of dust.

- Align the gears carefully. They should mesh smoothly.

- Attach the lever. Check if it moves easily up and down.

- Secure all screws tightly. Loose parts can cause problems.

- Test the lever’s function. It should respond correctly.

By following these steps, you ensure proper alignment and overall functionality.

What should I check after reassembling the power feed lever?

After reassembly, check that the lever moves smoothly and that all screws are tight. Testing helps catch any problems early.

Maintaining Your Metal Lathe Power Feed System

Routine maintenance tips to prolong the life of the power feed lever. Recommended cleaning and lubrication practices.To keep your metal lathe power feed system running smoothly, regular maintenance is key. Simple steps can make a big difference in its life. Here are some helpful tips:

- Clean the lever often to remove dust and grime.

- Check for any loose parts that might need tightening.

- Lubricate moving parts with machine oil.

- Inspect cables and connections for wear or damage.

Following these tips not only improves performance but also keeps your lathe safe for use.

How often should you clean and lubricate the power feed lever?

It’s best to clean and lubricate the power feed lever at least once a month. This helps prevent wear and keeps everything working well.

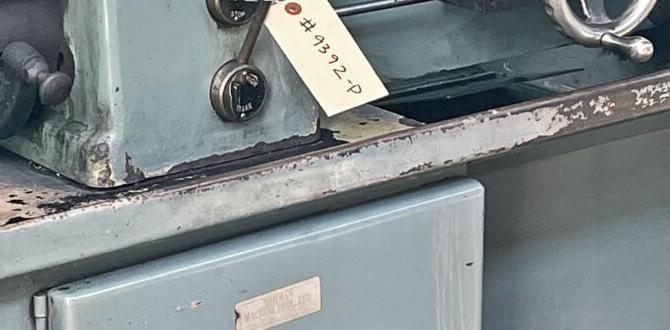

When to Seek Professional Help

Identifying situations that require expert intervention. How to find a qualified technician for repairs.Knowing when to call for expert help is important. If your metal lathe power feed lever starts acting weird, like suddenly deciding to dance instead of work, it’s time to get a pro. Don’t try to wrestle it back into place yourself; you might end up pulling a muscle or worse! Look for qualified technicians through local workshops, or ask for recommendations online. A quick search can connect you to the best in your area. Remember, a little help can save big headaches!

| Signs It’s Time for Help | Finding a Technician |

|---|---|

| Unusual noises | Check local directories |

| Inconsistent performance | Ask friends for referrals |

| Visible damage | Search online reviews |

Conclusion

In conclusion, repairing the metal lathe power feed lever is important for smooth operation. You should check for wear, clean parts, and replace damaged components. This will help your lathe work better and last longer. If you want to learn more, consider reading guides on lathe maintenance. Taking these steps can make a big difference in your projects!FAQs

What Are The Common Signs That Indicate A Problem With The Power Feed Lever On A Metal Lathe?If your metal lathe’s power feed lever has a problem, you might notice a few signs. First, the lever may feel loose or wobbly when you touch it. Second, the machine might not move as fast or smoothly as it should. Third, you might hear strange noises when you try to use the lever. If you see any of these signs, it’s time to check the lever!

How Do You Disassemble The Power Feed Lever Assembly For Inspection And Repair?To disassemble the power feed lever assembly, first, turn off the machine and unplug it. Next, look for screws or bolts that hold the assembly in place. Use a screwdriver or wrench to remove these carefully. Once the screws are out, gently pull apart the parts of the lever assembly. Now, you can inspect and repair any broken pieces.

What Tools And Materials Are Necessary For Repairing Or Replacing A Damaged Power Feed Lever?To fix a broken power feed lever, you need some tools and materials. First, grab a screwdriver to take off the old lever. You will also need a new lever to replace the broken one. Having some pliers can help if you need to pull out any tight parts. Finally, use some grease to make the new lever work smoothly.

What Safety Precautions Should Be Taken When Working On The Power Feed Mechanism Of A Metal Lathe?When working on the power feed mechanism of a metal lathe, you should always wear safety goggles to protect your eyes. Make sure the machine is turned off and unplugged before you start. Keep your hands away from moving parts to avoid injury. It’s also good to use tools that are in good shape and not damaged. Lastly, make sure your work area is clean and free of clutter to prevent trips and falls.

How Can I Prevent Future Issues With The Power Feed Lever On My Metal Lathe After Repair?To keep your power feed lever working well, always clean it after use. Make sure to check it for any dirt or grease. You should also lubricate it regularly to keep it moving smoothly. Finally, avoid using too much force when adjusting it. This will help you prevent future problems.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Problem With The Power Feed Lever On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe’s power feed lever has a problem, you might notice a few signs. First, the lever may feel loose or wobbly when you touch it. Second, the machine might not move as fast or smoothly as it should. Third, you might hear strange noises when you try to use the lever. If you see any of these signs, it’s time to check the lever!”}},{“@type”: “Question”,”name”: “How Do You Disassemble The Power Feed Lever Assembly For Inspection And Repair? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To disassemble the power feed lever assembly, first, turn off the machine and unplug it. Next, look for screws or bolts that hold the assembly in place. Use a screwdriver or wrench to remove these carefully. Once the screws are out, gently pull apart the parts of the lever assembly. Now, you can inspect and repair any broken pieces.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Necessary For Repairing Or Replacing A Damaged Power Feed Lever? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix a broken power feed lever, you need some tools and materials. First, grab a screwdriver to take off the old lever. You will also need a new lever to replace the broken one. Having some pliers can help if you need to pull out any tight parts. Finally, use some grease to make the new lever work smoothly.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working On The Power Feed Mechanism Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working on the power feed mechanism of a metal lathe, you should always wear safety goggles to protect your eyes. Make sure the machine is turned off and unplugged before you start. Keep your hands away from moving parts to avoid injury. It’s also good to use tools that are in good shape and not damaged. Lastly, make sure your work area is clean and free of clutter to prevent trips and falls.”}},{“@type”: “Question”,”name”: “How Can I Prevent Future Issues With The Power Feed Lever On My Metal Lathe After Repair? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your power feed lever working well, always clean it after use. Make sure to check it for any dirt or grease. You should also lubricate it regularly to keep it moving smoothly. Finally, avoid using too much force when adjusting it. This will help you prevent future problems.”}}]}