Have you ever thought about how machines can do amazing things? One fascinating tool is the metal lathe. This powerful device can shape metal into different forms. But did you know it can also work in reverse? That’s right! The metal lathe reverse operation adds a whole new dimension to metalworking.

Imagine you are a tinkerer in your garage. You’ve made some cool projects, but something feels off. You wish there was a way to fix your mistakes easily. With a metal lathe, especially during reverse operations, you can do just that!

Learning about the metal lathe reverse operation can open up new possibilities. It allows you to create unique pieces or simply clean up an error. It’s a handy skill for any aspiring craftsman. So, let’s dive into the exciting world of lathes and discover their reverse magic!

Understanding Metal Lathe Reverse Operation For Precision Work

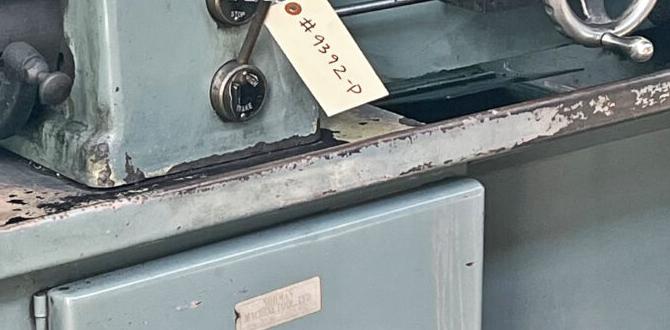

Metal Lathe Reverse Operation

Metal lathes are amazing tools that shape metal. Did you know you can make them run backward? This “reverse operation” allows for unique techniques. It can create threads and produce a smoother finish on certain materials. By reversing the spindle’s direction, you gain more control over the cutting process. This is especially useful when refining parts. Learning this technique can provide new opportunities for your projects. Isn’t it exciting to discover new methods in machining?Understanding Metal Lathe Basics

Explanation of what a metal lathe is. Key components and their functions.A metal lathe is a machine that turns metal to shape it into different forms. It works by rotating the metal piece while cutting tools carve it. Key parts of a lathe include:

- Headstock: It holds the spindle and motor.

- Tailstock: It supports the other end of the metal piece.

- Tool Rest: This holds the cutting tools in place.

- Bed: It provides a stable base for the lathe.

These parts work together to help create precise shapes and designs in metal. Learning how each part functions is essential for any hobbyist or professional.

What is a metal lathe used for?

A metal lathe is used for shaping metal into parts. It helps in making items like pipes, gears, and more. This makes it an important tool for engineers and builders.

Importance of Reverse Operation

Benefits of using reverse operation. Common applications in machining.Using reverse operation on a metal lathe is important. It helps create cleaner cuts and makes finishing easier. The benefits include:

- Improved accuracy: Reverse operation allows for precise adjustments.

- Better chip removal: It helps get rid of chips that can hinder work.

- Enhanced tool life: Tools last longer when used in both directions.

This technique is common in machining for tasks like:

- Threading: Making screws and bolts.

- Finishing: Smoothing surfaces for better quality.

- Facing: Leveling the end of a material.

What are the benefits of reverse operation?

Reverse operation improves accuracy, efficiently removes chips, and extends tool life. These benefits make machining smoother and more effective for various tasks.

How to Set Up a Metal Lathe for Reverse Operation

Stepbystep process for setup. Safety precautions to consider.Setting up your metal lathe for reverse operation can be easy. First, make sure the lathe is off and unplugged. Then, follow these steps:

- Check the manual for specific settings.

- Switch the belt to the reverse position.

- Adjust the speed according to your needs.

- Double-check your tool settings.

- Plug the lathe back in and turn it on.

Safety is key. Always wear safety glasses and gloves. Keep your workspace tidy. Never wear loose clothing that could get caught. These steps will help you work safely.

What tools do you need for reverse operation on a metal lathe?

You will need cutting tools, measuring tools, and safety gear like goggles. These tools will help you set up correctly and work safely.

Techniques for Effective Reverse Operation

Tips for maintaining precision during reverse turn. Common mistakes to avoid.To keep your precision sharp during reverse turns, there are some simple tricks. First, make sure to check your settings before starting. This helps avoid wobbly mistakes, like those times your pencil rolls away while you’re coloring! Second, focus on keeping the speed steady. Too fast, and you might create a “metal spaghetti.” Here’s a quick table of common mishaps to sidestep:

| Mistake | Solution |

|---|---|

| Going too fast | Adjust the speed slowly |

| Poor measuring | Double-check your measurements |

| Neglecting tool maintenance | Keep tools clean and sharp |

By sticking to these tips, you’ll avoid unnecessary blunders and keep your projects on track. Remember, slow and steady wins the lathe race!

Common Issues and Troubleshooting

Identifying problems during reverse operation. Solutions for common challenges.Running a metal lathe in reverse can lead to some hiccups. First, check your equipment for signs of wear or loose parts. Common problems include vibration sounds or unexpected stops. If you see these issues, it might be time for some maintenance. Here’s a quick guide on what to do:

| Issue | Solution |

|---|---|

| Vibration | Inspect and tighten all loose bolts. |

| Slipping | Check the belt tension and replace if worn. |

| No Response | Examine your power supply and connections. |

Regularly maintaining your lathe can save you from headaches. Remember, if your lathe isn’t happy, you won’t be either. Treat it well, and it will work wonders!

Advanced Techniques in Reverse Operation

Advanced practices for skilled machinists. Enhancing productivity with reverse features.For skilled machinists, mastering reverse features can make a huge difference. These advanced techniques can help save time and boost productivity. Imagine turning a project around faster than a squirrel on a sugar rush! With metal lathes, using reverse operation allows you to refine pieces quickly and accurately.

| Technique | Benefit |

|---|---|

| Quick Reversals | Reduces processing time |

| Precision Adjustments | Increases accuracy |

By embracing these features, machinists can unleash their creativity and efficiency. Fun fact: utilizing reverse operation can cut setup time by up to 40%! So, let those lathes spin, and let productivity soar!

Maintenance Tips for Longevity of Reverse Mechanisms

Routine checks for reverse components. Lubrication and care instructions.Keeping reverse mechanisms in good shape is vital for your metal lathe. Regular checks can help you spot issues early. Look for signs of wear, strange noises, or any dirt build-up. Together with routine checks, proper lubrication is essential. Use a high-quality lubricant and apply it often. Don’t forget to wipe away any excess to keep things clean.

- Inspect reverse components monthly.

- Lubricate moving parts every few weeks.

- Clean dirt or old oil regularly.

How do I maintain the reverse mechanism of a metal lathe?

To maintain the reverse mechanism, regularly check for wear and lubricate the parts. This simple care can prevent bigger problems. Regular upkeep extends the life of your machine.

Case Studies: Success Stories Using Reverse Operation

Examples of projects benefitting from reverse operation. Lessons learned and best practices from case studies.Using reverse operation in metal lathes has led to many successful projects. For example, a team was able to create precise gears for a machine. They found that reverse operation improved accuracy and saved time. Another project involved making art sculptures that needed unique shapes. The team learned that patience and practice are key to mastering this technique. Here are some best practices:

- Plan each step carefully before starting.

- Always check your measurements.

- Practice with scrap material first.

What are some successful projects using reverse operation?

Successful projects include creating accurate machine parts and unique art sculptures. These projects show how effective reverse operation can be.

What lessons can we learn?

Key lessons include careful planning, thorough measuring, and practicing first. These practices help ensure success in metalworking.

Conclusion

In summary, mastering reverse operation on a metal lathe gives you more control and flexibility. You can create different shapes and improve your skills. Remember to practice safety first when using your lathe. If you’re interested, explore online tutorials or guides to learn more about this technique. Let’s get started on your metalworking journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Reverse Operation:Sure! A metal lathe can reverse to help us make different shapes. When we switch it to reverse, the tool moves the other way. This helps us clean up mistakes or finish our work better. It’s like rewinding a movie so you can see a part again! Using reverse makes our projects look nice and neat.

Sure! Just send me the question you’d like me to answer, and I’ll help you out!

What Is The Purpose Of Reverse Operation In A Metal Lathe?The reverse operation in a metal lathe helps us change the direction of the tool. This can smooth out the metal or make different shapes. When we reverse, we can easily clean the piece or fix mistakes. It makes our work better and more precise.

How Do You Safely Engage The Reverse Mechanism On A Metal Lathe?To safely use the reverse mechanism on a metal lathe, first, make sure the machine is turned off. Check that your hands and clothing are clear of moving parts. Then, find the reverse switch and carefully flip it to “reverse.” Always keep your eyes on the workpiece while it runs. Once done, turn off the lathe again before reaching in to make any adjustments.

What Types Of Machining Operations Benefit From Using Reverse Rotation On A Lathe?Using reverse rotation on a lathe can help us with different tasks. It’s great for cleaning tools and making smoother cuts. We can also use it to remove small bits of material easily. This makes our work faster and helps keep things tidy. Reverse rotation really helps in finishing jobs better.

Are There Specific Types Of Lathe Tools That Are Designed To Be Used During Reverse Operation?Yes, some lathe tools work better when you spin the lathe in reverse. These tools help you make smoother cuts and get special shapes. They can be good for doing tricky designs. You just need to check if your tool can be used this way.

How Does Reversing The Spindle Rotation Affect Chip Removal And Surface Finish In Metalworking?When we reverse the spindle rotation in metalworking, it can change how chips are removed from the workpiece. This can help clear away chips faster, preventing them from piling up. A better chip removal can lead to a nicer surface finish. When the chips are removed well, the tool can work better and make smoother surfaces.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Reverse Operation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe can reverse to help us make different shapes. When we switch it to reverse, the tool moves the other way. This helps us clean up mistakes or finish our work better. It’s like rewinding a movie so you can see a part again! Using reverse makes our projects look nice and neat.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just send me the question you’d like me to answer, and I’ll help you out!”}},{“@type”: “Question”,”name”: “What Is The Purpose Of Reverse Operation In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The reverse operation in a metal lathe helps us change the direction of the tool. This can smooth out the metal or make different shapes. When we reverse, we can easily clean the piece or fix mistakes. It makes our work better and more precise.”}},{“@type”: “Question”,”name”: “How Do You Safely Engage The Reverse Mechanism On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely use the reverse mechanism on a metal lathe, first, make sure the machine is turned off. Check that your hands and clothing are clear of moving parts. Then, find the reverse switch and carefully flip it to reverse. Always keep your eyes on the workpiece while it runs. Once done, turn off the lathe again before reaching in to make any adjustments.”}},{“@type”: “Question”,”name”: “What Types Of Machining Operations Benefit From Using Reverse Rotation On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using reverse rotation on a lathe can help us with different tasks. It’s great for cleaning tools and making smoother cuts. We can also use it to remove small bits of material easily. This makes our work faster and helps keep things tidy. Reverse rotation really helps in finishing jobs better.”}},{“@type”: “Question”,”name”: “Are There Specific Types Of Lathe Tools That Are Designed To Be Used During Reverse Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some lathe tools work better when you spin the lathe in reverse. These tools help you make smoother cuts and get special shapes. They can be good for doing tricky designs. You just need to check if your tool can be used this way.”}},{“@type”: “Question”,”name”: “How Does Reversing The Spindle Rotation Affect Chip Removal And Surface Finish In Metalworking?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we reverse the spindle rotation in metalworking, it can change how chips are removed from the workpiece. This can help clear away chips faster, preventing them from piling up. A better chip removal can lead to a nicer surface finish. When the chips are removed well, the tool can work better and make smoother surfaces.”}}]}