Have you ever watched a metal lathe in action? It’s amazing how it turns raw metal into precise parts. The secret to a smooth operation lies within the metal lathe saddle adjustment.

So, what is a metal lathe saddle? It’s the part that holds the cutting tool steady as it moves along the workpiece. If it’s not adjusted correctly, problems can arise. Your piece might end up uneven or even damaged!

Did you know that even small adjustments can make a big difference? Just imagine how frustrating it would be to spend hours making something perfect, only to discover that one tiny adjustment ruined it.

In this article, we’ll explore the importance of metal lathe saddle adjustment. You’ll learn simple tips and tricks. Get ready to unlock the full potential of your metal lathe!

Metal Lathe Saddle Adjustment: A Comprehensive Guide

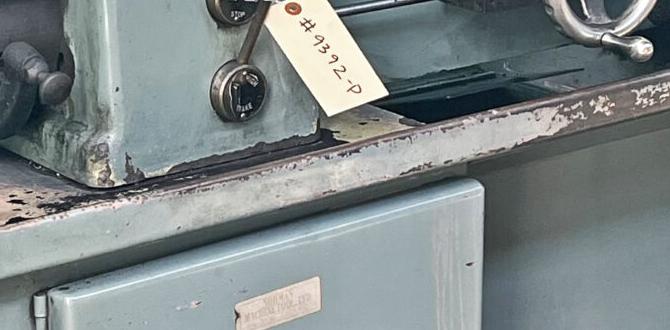

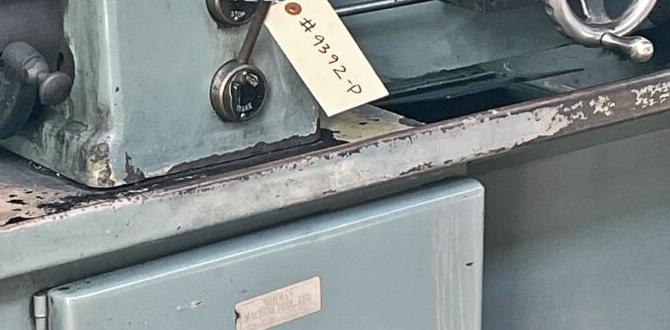

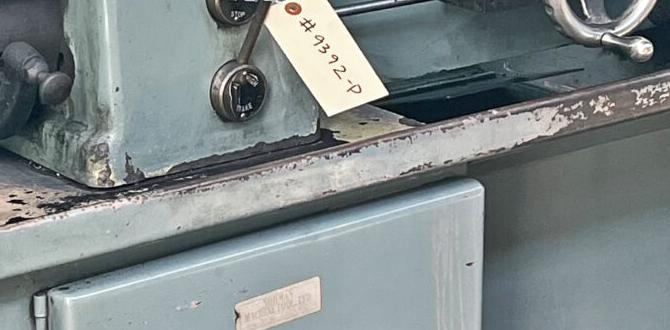

Metal Lathe Saddle Adjustment

Understanding metal lathe saddle adjustment is essential for smooth operation. Proper adjustment ensures precision in your work. Ever wondered why your lathe feels off? It could be due to a misaligned saddle. Regular checks can improve accuracy and extend the machine’s life. A well-set saddle means better cuts and a smoother finish on your projects. Remember, a little adjustment can lead to big improvements in your lathe’s performance. Taking time to adjust correctly is worth it!Understanding the Metal Lathe Saddle

Definition and function of the metal lathe saddle. Importance of proper saddle adjustment in machining.The metal lathe saddle is a critical piece of machinery. It holds the tool rest and moves back and forth on the bed. This allows for precise cutting and shaping of materials. Think of it as the lathe’s trusty sidekick, always ready to help! Proper adjustment of the saddle is key. If it’s off, you could end up with funny-looking shapes instead of perfect designs. Remember, a well-adjusted saddle makes for smooth cuts and happy machinists!

| Function | Importance |

|---|---|

| Holds the tool rest | Ensures accuracy in machining |

| Moves easily on the bed | Prevents material waste |

So, to sum it up, the saddle is where the magic happens. Proper adjustment means getting it right every time and avoiding catastrophic design disasters!

Common Issues Caused by Improper Saddle Adjustment

Symptoms of misalignment and their impacts on workpieces. How improper adjustment can lead to tool wear and damage.Improper saddle adjustment can cause big problems. You may notice strange marks on your workpiece. These signs show that the machine isn’t working right. Misalignment can also make your tools wear out faster. They can even get damaged! Here are some common symptoms of these issues:

- Uneven cuts on materials

- Increased vibration during machining

- Excessive heat generation

- Frequent tool breakage

Being aware of these signs helps maintain quality and prolongs tool life. Keep an eye on the machine to ensure proper function!

What are the effects of improper adjustment on tools?

Improper adjustments can lead to quicker tool wear and potential breakage. These problems make machining less effective and can cost time and money.

Tools Required for Saddle Adjustment

List of essential tools for making adjustments. Safety equipment necessary during the process.To tackle saddle adjustments on a metal lathe, you’ll need a few trusty tools. First, grab a wrench to make tight spots more friendly. A screwdriver is key for loosening or tightening screws. Don’t forget your trusty dial indicator to check precision! Safety is vital too. Always wear safety goggles – nobody wants flying metal bits in their eyes. A good pair of work gloves will keep your hands safe. Now, you’re ready to adjust like a pro!

| Tool | Purpose |

|---|---|

| Wrench | For loosening/tightening parts |

| Screwdriver | To adjust screws |

| Dial Indicator | To check accuracy |

| Safety Goggles | To protect eyes |

| Work Gloves | To protect hands |

Step-by-Step Guide to Adjusting the Metal Lathe Saddle

Detailed instructions for assessing the current adjustment. Procedures for tightening or loosening saddle components.First, check the current metal lathe saddle adjustment. Look for any gaps or misalignment—it’s like searching for the missing sock! Use a feeler gauge for precision. Next, if things don’t seem quite right, you may need to tighten or loosen some components. Grab a wrench and adjust the bolts around the saddle. Remember, a little twist can make a big difference, so go slow. If it gets too tight, your lathe might feel like a grumpy cat!

| Adjustment Task | Tool Needed | Action Required |

|---|---|---|

| Check Alignment | Feeler Gauge | Measure gaps |

| Tighten Bolts | Wrench | Turn clockwise |

| Loosen Bolts | Wrench | Turn counterclockwise |

Advanced Techniques for Precision Adjustment

Utilizing measurement tools for enhanced accuracy. Techniques for compensating wear and tear on the saddle.Using measurement tools is like having a superhero sidekick for your metal lathe! They help you make super precise adjustments, ensuring everything runs smoothly. Want to boost accuracy? Grab a dial indicator or caliper—they make life easier!

Wear and tear on the saddle? Fear not! You can compensate by fine-tuning the screws or replacing worn parts. Remember, even lathes have bad hair days! Give them a little TLC and they’ll be back to their shiny selves.

| Measurement Tools | Benefits |

|---|---|

| Dial Indicator | High accuracy for setup |

| Caliper | Easy to read and versatile |

Maintenance Tips for Longevity of Saddle Components

Regular inspection routines to ensure optimal performance. Lubrication practices that extend the life of the saddle.Keeping saddle components in great shape is key. Regular checks help catch problems early. Inspect for wear and tear, loose parts, and dirt. A good routine boosts performance.

Lubrication is vital too. The right oil helps reduce friction and prevents rust. Use a quality lubricant on moving parts to extend the saddle’s life. Follow these tips:

- Check for dirt or dust buildup often.

- Apply lubricant every few weeks.

- Keep screws tight to avoid wobbling.

How can I maintain my saddle components?

Regular inspections and proper lubrication are essential for maintenance. They help your saddle last longer and work better.

Troubleshooting Common Saddle Adjustment Problems

Identifying and resolving typical adjustment challenges. Expert tips for quick fixes during operation.Sometimes, saddle adjustments can act like a stubborn mule, refusing to budge. First, check for any loose screws or bolts. Tighten them up, and it might just work like magic! If your lathe makes funny noises, it could mean the saddle isn’t aligned. Grab a tool and give it a nudge. For quick fixes, remember that regular checks can save you time and headaches. So, let’s take a look at some typical problems and how to handle them:

| Problem | Tip |

|---|---|

| Loose saddle | Tighten all screws and bolts. |

| Saddle misalignment | Adjust the position carefully. |

| Unusual noises | Inspect for misalignments and wear. |

FAQs on Metal Lathe Saddle Adjustment

Common questions and expert answers regarding saddle adjustment. Discussing myths and misconceptions about the adjustment process.Many folks have questions about saddle adjustments, and that’s completely normal! Here are some common queries and their answers from the pros. For example, one myth is that adjustments are always complicated. In reality, most adjustments are as simple as tightening a screw! Answering questions like, “How often should I adjust my saddle?” Why, that’s once every blue moon, or every few months! Below is a handy table to clear up the most popular myths:

| Myth | Truth |

|---|---|

| Adjustments ruin the lathe. | Proper adjustments enhance performance. |

| You need special tools. | A simple wrench usually does the trick! |

| It takes hours to adjust. | Most adjustments take only a few minutes! |

Stay curious and happy lathe-ing!

Conclusion

In summary, adjusting the metal lathe saddle is important for smooth operation. It helps improve precision and quality of your work. You can check and tighten bolts for better control. Remember to clean the saddle regularly. For more detailed tips, explore instructional videos or manuals. With practice, you’ll master the adjustments and enhance your lathe skills!FAQs

Sure! Here Are Five Questions Related To Metal Lathe Saddle Adjustment:Sure! Here are five questions about adjusting the saddle on a metal lathe, which is a machine that shapes metal. You might want to know how to check if the saddle is too tight. You can also ask how to make it fit better, or how often to check it. Another question might be about what tools you need. Finally, you could wonder why it’s important to adjust the saddle.

Of course! Please provide the question you’d like me to answer.

What Are The Common Signs That Indicate A Metal Lathe Saddle Requires Adjustment?You might notice a few signs if your metal lathe saddle needs adjustment. First, the cuts on your metal might look uneven or rough. Second, the lathe could make strange noises while working. Third, the saddle may feel loose or wobbly when you move it. If you see these signs, it’s time to check and adjust the saddle.

How Do You Properly Measure The Alignment Of A Metal Lathe Saddle Before Making Adjustments?To check the alignment of a metal lathe saddle, you need a dial gauge. First, place the dial gauge on the saddle and touch its tip to the bed of the lathe. Next, move the saddle along the bed and watch the dial gauge. If the number on the gauge changes, the saddle might need adjustment. Make small changes to get it aligned correctly.

What Tools Are Typically Needed For Adjusting The Saddle On A Metal Lathe?To adjust the saddle on a metal lathe, you usually need a few tools. You will need a wrench to loosen the bolts. A screwdriver helps turn screws or make small adjustments. A ruler or caliper is useful for measuring. These tools make it easier to move and level the saddle.

How Does Improper Saddle Adjustment Affect The Accuracy And Finish Of A Workpiece On A Lathe?If the saddle on a lathe is not set right, it can make your workpiece uneven. This means the cutting tool might not touch it evenly. As a result, you could end up with rough edges or parts that don’t fit well. We want our workpieces to be smooth and accurate, so it’s important to adjust the saddle properly.

What Are The Step-By-Step Procedures For Adjusting The Saddle On A Specific Type Of Metal Lathe?To adjust the saddle on a metal lathe, follow these steps: 1. First, turn off the lathe and unplug it for safety. 2. Next, check the saddle for any loose screws. Use a wrench to tighten them if needed. 3. Then, look at the ways, which are the metal tracks the saddle moves on. 4. If the saddle is too tight or too loose, you may need to adjust the gibs, which are small metal pieces. 5. Finally, after making adjustments, test the saddle by moving it back and forth. Make sure it moves smoothly.