Have you ever wondered how metalworkers make precise cuts on a lathe? One key part of this process is the metal lathe tailstock. This piece of equipment helps hold tools or workpieces in place. But did you know that adjusting the tailstock barrel can greatly improve your work?

Imagine trying to create a perfect cylinder. Without the right adjustment, your work can quickly go off track. Tailstock barrel adjustment may seem tricky at first. But with the right tips, it becomes easy and enjoyable!

In this article, we’ll explore how to adjust your metal lathe tailstock barrel. You’ll learn simple steps to get it just right. Plus, we’ll share some common mistakes to avoid. Get ready to take your lathe skills to the next level!

Metal Lathe Tailstock Barrel Adjustment Techniques Explained

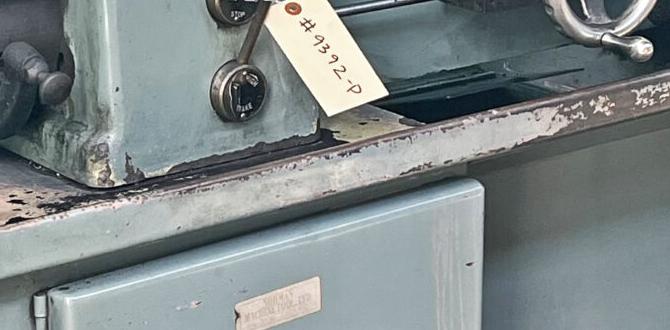

Metal Lathe Tailstock Barrel Adjustment

Proper metal lathe tailstock barrel adjustment is essential for accurate machining. This ensures that the workpiece stays securely in place while spinning. Did you know that even a slight misalignment can ruin your project? Learning how to adjust the tailstock barrel allows you to increase stability and precision. With simple tools, this is an easy fix. Mastering this skill can enhance your overall crafting experience, making your projects more successful and enjoyable.Understanding the Metal Lathe Tailstock

Components and functions of the tailstock. Importance of tailstock alignment in machining accuracy.The tailstock is a key part of a metal lathe. It holds the tool steady and helps with precise cuts. The main components include:

- Barrel: Allows for adjustments.

- Quill: Holds the cutting tools.

- Clamping mechanism: Keeps everything in place.

Proper alignment of the tailstock is vital. If it’s off, the cuts can be inaccurate. This can lead to waste and extra work. A well-aligned tailstock helps ensure quality in every piece you create.

Why is tailstock alignment important?

Alignment directly affects machining accuracy. If the tailstock is not aligned, the finished product may not fit as needed. This can cause errors in projects.

Common Issues with Tailstock Barrel Adjustment

Identifying signs of misalignment. Consequences of improper tailstock adjustments.Setting up the tailstock correctly can be a tricky task. A misaligned tailstock can cause issues like uneven cuts or poor finish quality. Watch out for signs such as wobbling or rough edges on your workpiece. If your product looks like it just came out of a soda can accident, it’s time to adjust! Proper adjustments are key; they ensure your machine runs smoothly, and that helps you work efficiently. Remember, even the best lathes can’t fix a bad tailstock!

| Signs of Misalignment | Consequences |

|---|---|

| Wobbling workpiece | Rough edges |

| Poor finish quality | Damage to tools |

| Uneven cuts | Increased wear |

Tools Required for Tailstock Barrel Adjustment

Essential tools for adjustment and calibration. Safety gear and best practices when working with lathe machinery.To adjust the tailstock barrel, you need some important tools. Having the right tools makes everything easier and safer. Start with a wrench for bolts. A caliper helps measure accurately. You’ll also need a screwdriver for small adjustments. Lastly, use a level to check the alignment.

Don’t forget safety! Always wear safety goggles and gloves. Stay focused, and keep your workspace tidy. This helps prevent accidents.

What tools are essential for tailstock barrel adjustment?

Essential tools include a wrench, caliper, screwdriver, and level.

Best safety practices include:

- Wearing safety goggles

- Using gloves

- Keeping a clean workspace

- Staying focused

Step-by-Step Guide to Adjusting the Tailstock Barrel

Initial inspection and measurement techniques. Detailed process for adjusting the tailstock barrel.To start, check your tailstock for wear and damage. Look closely at the barrel and other parts. Measure the distance between the tailstock center and the lathe center. Use a caliper for accuracy. If adjustments are needed, follow this process:

- Loosen the tailstock locking screw.

- Slide the barrel until it aligns properly.

- Tighten the screw gently to secure it.

This ensures better accuracy while working on your lathe.

Why is tailstock adjustment important?

Proper tailstock barrel adjustment keeps your work precise. It reduces errors and extends tool life. Accuracy plays a key role in quality projects.

Tips for Achieving Optimal Tailstock Alignment

Best practices for routine maintenance. Techniques for ensuring accurate adjustments.To keep your metal lathe tailstock working like a charm, routine maintenance is key. Clean it regularly to remove dust and debris. A little grease can work wonders too! For accurately adjusting the tailstock, try using a dial indicator. This tool helps you see if everything is aligned properly. If the numbers look off, don’t panic! Just make small tweaks until you get it right. Remember, the goal is precision, and who doesn’t love a perfectly aligned tailstock?

| Best Practices | Techniques for Adjustments |

|---|---|

| Clean the tailstock regularly. | Use a dial indicator for accuracy. |

| Add grease to moving parts. | Make small adjustments for precision. |

| Inspect for wear and tear. | Check alignment frequently. |

Using a Dial Indicator for Precise Adjustment

Setting up a dial indicator for measurements. Interpreting dial readings to make adjustments.To achieve perfect adjustments, start by securing the dial indicator in place. Make sure it’s snug, like your favorite pair of sneakers. Next, touch the dial to the tailstock and gently move it as needed. Watch the reading closely, as it’s your guide to precision!

| Dial Reading | Action |

|---|---|

| 0.01 mm | Make a slight adjustment |

| 0.05 mm | Adjust more carefully |

| 0.1 mm or more | Time to rethink your setup! |

Once you get the reading, it’s all about making quick tweaks. A little turn here and there brings you closer to the sweet spot. Remember, even the tiniest change can make a big difference. So, use that dial like a magician uses a wand, and you’ll cast the right spell on your metal lathe.

Case Studies: Successful Tailstock Adjustments

Realworld examples of effective adjustments. Lessons learned from professional machinists.Many machinists have tackled tailstock adjustments, learning valuable lessons along the way. For instance, Bob, a seasoned pro, once struggled with a crooked cut. He fixed it by fine-tuning his tailstock, leading to a perfectly smooth finish. His advice? “Check your alignment before you start; it saves a world of trouble!”

Here are some key takeaways from successful adjustments:

| Machinist | Adjustment Technique | Outcome |

|---|---|---|

| Bob | Align tailstock with laser tool | Smooth cuts and happy machine |

| Sara | Loosen screws for better grip | Stable workpiece, no wobble! |

These tales show that a small tweak can make a big difference. Remember, even the best machinists started with a few bumps along the way!

Frequently Asked Questions About Tailstock Adjustments

Addressing common concerns and misconceptions. Expert advice for troubleshooting adjustment problems.Many people have questions about tailstock adjustments. Common concerns include how to make the right adjustments and fix problems. Misconceptions can lead to frustration. Understanding these issues can help you work better.

When troubleshooting, remember:

- Check for wear and tear. Damaged parts can affect adjustments.

- Ensure the barrel is clean. Dirt can stop it from moving smoothly.

- Use a square tool. This helps to align your lathe correctly.

Expert advice suggests taking your time. Sometimes, small tweaks make a big difference. Don’t rush adjustments. Practice makes perfect!

Additional Resources and Further Reading

Recommended books, online tutorials, and forums. Links to expert videos and workshops on lathe maintenance and usage.Learning about metal lathe tailstock barrel adjustment can be easier with great resources. Here are some suggestions to boost your knowledge:

- Books: Look for titles like “Lathe Basics” and “Essential Machining”. They provide clear instructions and tips.

- Online Tutorials: Websites like YouTube have many videos showing proper techniques for adjustments.

- Forums: Join forums such as Tech Talk or Metalworking on Reddit. They are great places to ask questions and share experiences.

Also, check out expert videos and workshops, where you can see real-time demonstrations. These resources can make learning easier and more enjoyable!

Where can I find expert videos on lathe maintenance?

You can find expert videos on YouTube and expert sites like Udemy. They offer step-by-step guides that help you learn effectively.

Are there online forums for metal lathe users?

Yes, places like Machinists’ Forum and Practical Machinist are excellent for connecting with other users. You can exchange tips and ask questions.

Conclusion

In conclusion, adjusting the tailstock barrel on a metal lathe is important for accuracy. You can easily ensure your workpieces are aligned properly. Remember to check the barrel frequently and make adjustments when needed. For more tips, consider exploring guides or videos on metal lathe techniques to improve your skills further. Happy turning!FAQs

What Are The Common Signs That Indicate The Tailstock Barrel On A Metal Lathe Needs Adjustment?If the tailstock barrel on a metal lathe needs adjustment, you might notice some signs. First, it may not hold your tool tightly when you push it in. Second, you could see that your work is not straight or even. Third, you might hear strange noises while the machine runs. Lastly, it could be harder to move the barrel in or out smoothly.

How Can I Adjust The Tailstock Barrel To Ensure Proper Alignment For Accurate Machining?To adjust the tailstock barrel, first make sure the machine is turned off. Next, loosen any screws on the tailstock. You can move the barrel left or right, so it lines up with the spinning part. Tighten the screws once it looks good. Now you’re ready to machine accurately!

What Tools Are Required To Make Adjustments To The Tailstock Barrel On A Metal Lathe?To adjust the tailstock barrel on a metal lathe, you need a few tools. First, grab a wrench to loosen the screws. Then, use a measuring tool, like a ruler or caliper, to check the length. Finally, you might need a screwdriver to tighten everything back up. Make sure to check your work before starting!

What Is The Proper Procedure For Checking The Tailstock Alignment After Making An Adjustment?To check the tailstock alignment, first, slide the tailstock up to the spindle. Then, use a test bar or a straight piece of material. Make sure it touches both the tailstock and the spindle. Next, check if the bar is straight and not bending. If it is straight, the tailstock is aligned. If not, adjust it again and check once more.

Are There Specific Maintenance Tips For Keeping The Tailstock Barrel And Its Mechanism In Optimal Condition?To take care of the tailstock barrel, keep it clean and oiled. Wipe it with a cloth to remove dust and dirt. You should also check if it moves smoothly. If it feels stiff, add a little oil to help it work better. Regularly check for any loose parts and tighten them if needed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate The Tailstock Barrel On A Metal Lathe Needs Adjustment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock barrel on a metal lathe needs adjustment, you might notice some signs. First, it may not hold your tool tightly when you push it in. Second, you could see that your work is not straight or even. Third, you might hear strange noises while the machine runs. Lastly, it could be harder to move the barrel in or out smoothly.”}},{“@type”: “Question”,”name”: “How Can I Adjust The Tailstock Barrel To Ensure Proper Alignment For Accurate Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock barrel, first make sure the machine is turned off. Next, loosen any screws on the tailstock. You can move the barrel left or right, so it lines up with the spinning part. Tighten the screws once it looks good. Now you’re ready to machine accurately!”}},{“@type”: “Question”,”name”: “What Tools Are Required To Make Adjustments To The Tailstock Barrel On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock barrel on a metal lathe, you need a few tools. First, grab a wrench to loosen the screws. Then, use a measuring tool, like a ruler or caliper, to check the length. Finally, you might need a screwdriver to tighten everything back up. Make sure to check your work before starting!”}},{“@type”: “Question”,”name”: “What Is The Proper Procedure For Checking The Tailstock Alignment After Making An Adjustment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the tailstock alignment, first, slide the tailstock up to the spindle. Then, use a test bar or a straight piece of material. Make sure it touches both the tailstock and the spindle. Next, check if the bar is straight and not bending. If it is straight, the tailstock is aligned. If not, adjust it again and check once more.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Tips For Keeping The Tailstock Barrel And Its Mechanism In Optimal Condition? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of the tailstock barrel, keep it clean and oiled. Wipe it with a cloth to remove dust and dirt. You should also check if it moves smoothly. If it feels stiff, add a little oil to help it work better. Regularly check for any loose parts and tighten them if needed.”}}]}