Have you ever wondered how machines create precise parts? One important tool in a workshop is the metal lathe. This machine helps shape metal into many forms. But did you know that the tailstock of a lathe has a special job too? It can be used for drilling holes! This clever feature makes the metal lathe even more useful.

Imagine you want to make a new handle for your tool. You can use the metal lathe to shape the metal and the tailstock to drill holes for screws. This makes your project stronger and more reliable. Did you know? Many skilled makers use the tailstock to quickly add holes, saving time and effort.

In this article, we will explore the exciting world of tailstock drilling. You’ll learn how to use it and why it’s so helpful. Are you ready to discover new skills and improve your projects? Let’s dive in!

Metal Lathe Tailstock Drilling: Essential Techniques And Tips

Exploring Metal Lathe Tailstock Drilling

Metal lathe tailstock drilling is a crucial skill for any craftsman. The tailstock holds drill bits and helps create accurate holes in metal pieces. It supports the workpiece while spinning, making drilling easier and more precise. Curious how it works? Imagine crafting a perfect cylindrical shape, needing precise holes! With the tailstock, you can achieve perfect alignment every time. Understanding this tool can elevate your metalworking projects significantly, enhancing both quality and efficiency.Understanding the Metal Lathe Tailstock

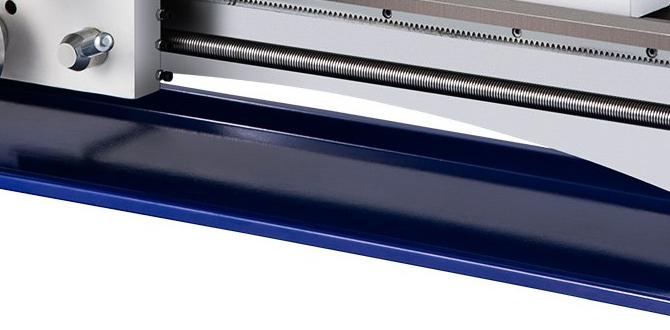

Definition and purpose of the tailstock in metal lathes. Parts and components of the tailstock.The tailstock is like the best buddy of a metal lathe. It helps hold things steady while you work. This part can be moved back and forth, making it easy to drill holes or add tools. Typically, it has a quill and a handwheel for simple adjustments.

| Parts of the Tailstock | Function |

|---|---|

| Quill | Moves in and out to hold tools |

| Handwheel | Lets you adjust the quill easily |

| Locking mechanism | Keeps everything in place |

Without the tailstock, working with a metal lathe would be like trying to eat soup with a fork—messy and hard! Understanding this part makes your projects smoother and more fun.

Importance of Drilling with the Tailstock

Advantages of using the tailstock for drilling operations. Common applications and scenarios for tailstock drilling.Using the tailstock for drilling is like having a trusty sidekick in a superhero movie. It helps make your drilling operations more stable and precise. This means fewer mistakes and better results—who wouldn’t want that? Common scenes for tailstock drilling include making holes in long pieces of wood or metal, where strength and support are key. In addition, it’s perfect for aligning your work. Just remember, a well-placed drill hole is like a great punchline: it can really make everything come together.

| Advantage | Application |

|---|---|

| Stability | Long materials |

| Precision | Aligning holes |

Setting Up the Tailstock for Drilling

Stepbystep guide to align and secure the tailstock. How to choose the right drill bit for your project.Aligning the tailstock for drilling is like getting your dance partner right before a big performance! First, slide the tailstock into place on the lathe. Tighten the clamp so it won’t budge. Next, use a drill bit that fits your project. For softer materials, a twist drill bit works wonders, while a spade bit is best for larger holes. Check the table below to see the differences!

| Drill Bit Type | Best For |

|---|---|

| Twist Bit | Soft materials like wood |

| Spade Bit | Larger holes in wood |

| Brad Point Bit | Precise drilling in wood |

Choosing wisely can make your project easier and maybe even fun! Remember, the right cocktail of tools is key to your success. Cheers to drilling!

Techniques for Effective Tailstock Drilling

Optimal drilling speeds and feeds. Tips for maintaining consistent pressure and depth.Drilling with a tailstock can be a breeze if you know a few tricks! First, choose the right speeds and feeds. Too fast? You might end up with a mini volcanic eruption instead of a hole! Aim for optimal settings to prevent overheating. Next, consistent pressure is key. Picture holding a teddy bear: gentle but firm! Maintain the same pressure while drilling to ensure even depth. Don’t forget to take breaks; even machines need a sip of oil now and then!

| Technique | Tip |

|---|---|

| Speed | Use the recommended RPM for your material! |

| Pressure | Keep it steady for a clean drill! |

| Depth | Check your depth frequently! |

Troubleshooting Common Drilling Issues

Identifying common problems (e.g., drill bit binding, misalignment). Solutions and preventative measures for smooth operations.Drilling can sometimes go wrong. Common issues include drill bit binding and misalignment. These problems can cause frustration and slow down your work. Remember, a smooth operation is key. Here are some tips:

- Check if the drill bit is sharp.

- Make sure the tailstock and drill bit are aligned.

- Use the right speed for the material.

- Lubricate the drill bit for easier use.

By following these steps, your drilling should be more efficient and enjoyable!

What causes drill bit binding?

Drill bit binding can happen due to debris build-up or a dull bit. If the bit is not sharp, it can get stuck. Always keep your tools clean and well-maintained.

How to prevent misalignment?

- Ensure the tailstock is locked properly.

- Double-check measurements before starting.

- Adjust the setup if you see any wobbling.

Maintenance of the Tailstock

Routine checks and servicing tips to keep the tailstock in good condition. Importance of lubrication and cleaning.Taking care of your tailstock is crucial for smooth metal lathe drilling. Regular checks can help prevent issues. Look for wear and tear, and keep it clean. A dirty tailstock is like a cookie without chocolate chips—just not right!

Lubrication is key. It keeps everything moving effortlessly and avoids rust. Apply oil to the sliding parts and wipe off excess to prevent dust. The happier the tailstock, the better your projects will turn out. So, grab that cloth and give it a polish!

| Maintenance Task | Frequency |

|---|---|

| Clean Tailstock | Every Use |

| Check for Wear | Weekly |

| Lubricate Moving Parts | Monthly |

Keep these tips in mind, and your tailstock will work like a champ. Remember, a well-maintained tailstock is your best friend in metal lathe drilling!

Advanced Techniques for Tailstock Drilling

Utilizing attachments and accessories for enhanced drilling. Exploring taper drilling and other specialized methods.Using special attachments can make tailstock drilling even better. For example, a drilling attachment helps you drill holes more accurately. Taper drilling is another cool trick. It lets you create cones instead of simple holes, like making an ice cream cone! Other advanced methods include using special bits for different materials. Check out this handy table for quick tips:

| Technique | Benefit |

|---|---|

| Drilling Attachments | Improves accuracy |

| Taper Drilling | Creates unique shapes |

| Special Bits | Works with various materials |

So, don’t be shy! Flare your creativity and explore these techniques. You’ll be a pro in no time! Remember, practice makes perfect, even if it means getting a bit messy!

Safety Considerations in Tailstock Drilling

Essential safety gear and precautions. Best practices to avoid accidents and injuries during operation.Using a metal lathe for tailstock drilling needs safety first. Always wear essential gear to protect yourself. This includes safety goggles, gloves, and a face mask. These items keep you safe from flying debris and harmful dust.

Follow these best practices:

- Keep hands away from moving parts.

- Secure all materials before starting.

- Stay focused and do not rush.

- Know how to turn off the machine quickly.

By following these tips, you can reduce the chance of accidents and enjoy safe drilling.

What safety gear is needed for tailstock drilling?

Always wear safety goggles, gloves, and a face mask. These items protect you from harm.

Conclusion

In conclusion, the metal lathe tailstock is essential for drilling accurately. It stabilizes your workpiece and ensures precision. Understanding its parts and functions helps you improve your skill. Now that you know how to use it, try practicing on your own project. For more tips, you can read guides about metalworking or watch tutorial videos online. Happy drilling!FAQs

Sure! Here Are Five Related Questions About Metal Lathe Tailstock Drilling:Sure! A metal lathe tailstock helps us drill holes in metal pieces. We move the tailstock to position it over the part we want to drill. When we turn the handle, the drill bit goes down and makes the hole. It’s like using a big pencil to make a hole in the wood, but we use metal instead! Always be careful and follow safety rules when using machines.

Of course! Please provide the question you would like me to answer.

What Is The Primary Function Of A Tailstock In A Metal Lathe, And How Does It Aid In Drilling Operations?The tailstock is a part of a metal lathe. Its main job is to hold tools or workpieces steady. When we drill holes, the tailstock helps keep everything in place. This makes it easier to drill straight and accurate holes. So, it’s very important for good drilling!

What Are The Key Components Of A Tailstock Used For Drilling On A Metal Lathe, And What Are Their Specific Purposes?A tailstock on a metal lathe has three key parts. First, there’s the tailstock body, which holds everything together. Second, the quill moves in and out. You use it to drill holes. Lastly, the handwheel lets you easily move the quill to adjust the position. Each part helps you drill accurately and safely.

How Do You Properly Align The Tailstock With The Workpiece To Ensure Accurate Drilling With A Metal Lathe?To align the tailstock with the workpiece, first, make sure the lathe is off. Then, move the tailstock close to the end of your piece. Next, line up the center of the tailstock with the center of the workpiece. You can do this by adjusting the tailstock until it matches perfectly. Finally, tighten the tailstock to hold it in place so you can drill accurately.

What Types Of Drill Bits Are Suitable For Use With The Tailstock Of A Metal Lathe, And How Do You Choose The Correct Size For Your Project?You can use twist drill bits with the tailstock of a metal lathe. These bits are good for making holes. To choose the right size, think about how big the hole needs to be. Check your project plans or measure the spot where you want to drill. Always pick a bit that matches those measurements.

What Safety Precautions Should Be Taken When Using The Tailstock For Drilling To Prevent Accidents And Ensure Effective Operation?When using the tailstock for drilling, always wear safety glasses to protect your eyes. Make sure the drill bit is tight and secure before starting. Keep your hands away from the spinning parts. Stand clear and keep the area clean to avoid tripping. Finally, always follow your teacher’s or adult’s instructions for safety.