Have you ever wondered how metal pieces are shaped into stunning designs? A metal lathe is a tool that turns this dream into reality. It helps create everything from simple gears to complex shafts used in machinery.

One key part of the lathe is the toolbit holder. But what makes this part so important? The dimensions of the toolbit holder can change everything. If it’s too big or too small, the tool won’t work right. Imagine trying to fit a big shoe on a small foot—it’s just not going to happen!

Fun fact: the right metal lathe toolbit holder dimensions can improve the accuracy of your cuts. This can save time and make your projects look better. Curious about what to look for? Read on to discover how choosing the right size can transform your work with metal lathes!

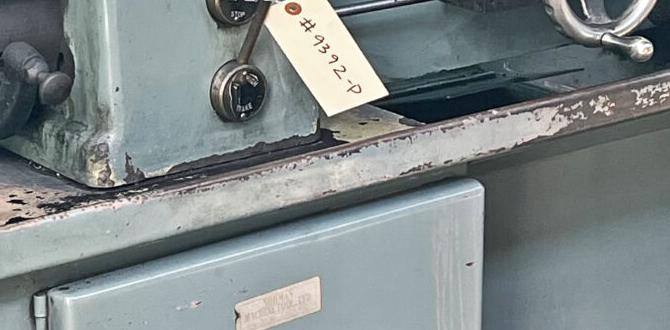

Metal Lathe Toolbit Holder Dimensions: Essential Guide

Metal Lathe Toolbit Holder Dimensions

Finding the right dimensions for a metal lathe toolbit holder is crucial for your projects. You learn about common sizes and how they fit different lathe models. Knowing these dimensions helps you select the correct toolbit holder, which improves accuracy and efficiency when working with metal. Did you know that even a small change in size can affect performance? Understanding these details can take your machining skills to the next level!Understanding Toolbit Holders

Definition and purpose of toolbit holders. Importance of precision in machining processes.Toolbit holders are special parts that secure toolbits to a machine. They keep the toolbits steady while cutting materials. This is important for making precise and clean cuts. A small mistake can lead to big problems in machining.

Precision is key in machining. It ensures that parts fit together well. This improves the overall quality of the final product. Accurate toolbit holders help in achieving this precision.

Why Are Toolbit Holders Important?

Toolbit holders are crucial for safe and accurate machining. They help prevent toolbit movement, which can ruin workpieces. Proper dimensions keep everything aligned and working smoothly.

- Ensure correct toolbit position

- Enhance cutting accuracy

- Minimize tool wear and tear

- Boost machining efficiency

Standard Dimensions for Toolbit Holders

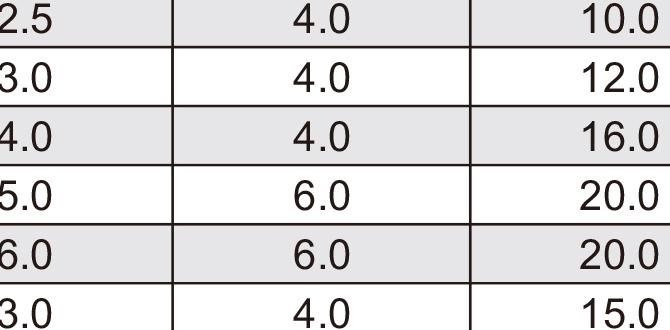

Commonly used dimensions in the industry. Variations based on specific lathe models.Toolbit holders come in many sizes, just like ice cream flavors. The most common dimensions are often around ½ inch, ¾ inch, and even an inch wide! However, specific lathe models can be picky. They may have their own unique sizes, so it’s like trying to fit a square peg in a round hole if you don’t check. Here’s a quick look at typical toolbit holder dimensions:

| Holder Type | Width (inches) | Height (inches) |

|---|---|---|

| Standard | 0.5 | 1.25 |

| Heavy Duty | 0.75 | 1.5 |

| Mini Lathe | 0.375 | 1.0 |

So remember, before you start working, always check your machine’s manual. That way, you won’t end up using a coffee cup instead of a toolbit holder!

Factors Influencing Toolbit Holder Dimensions

Material considerations and their impact on size. Influence of lathe specifications on holder dimensions.Many factors can affect the size of a toolbit holder. First, the material used matters. Strong materials like steel can support a larger holder, while lighter materials need smaller sizes. The lathe’s specifications also play an important role. A bigger lathe often requires a larger holder for stability. Here are key points:

- Material Type: Affects strength and weight.

- Lathe Size: Larger lathes usually need bigger holders.

- Usage: Different tasks may require specific dimensions.

What materials affect toolbit holder dimensions?

The materials impact the strength and size. Strong materials let you use larger holders. Lightweight materials may need smaller designs.

Precision and Tolerance in Toolbit Holders

Importance of maintaining proper tolerances. Common tolerance specifications for various holders.Proper tolerances in toolbit holders are very important. They ensure that tools fit perfectly, allowing for smooth and precise cutting. Poor tolerances can lead to mistakes and damage. Common specifications for holders include:

- Diameter: Usually around 1 inch

- Length: Often between 3 to 6 inches

- Width: Generally 0.5 to 0.75 inch

Keeping track of these measurements helps maintain quality in workpieces and boosts efficiency in machining.

What are acceptable tolerances for toolbit holders?

Common tolerances range from ±0.001 inches up to ±0.005 inches. These small measurements make a big difference in achieving accuracy. Even a tiny error can lead to problems while working.Custom Toolbit Holder Dimensions

When and why to consider custom dimensions. Process for designing and fabricating custom holders.Sometimes, standard toolbit holders don’t fit your needs. Custom dimensions can be important. They help you get the best fit for your metal lathe. Custom holders also boost accuracy and performance. To design and make them, follow these steps:

- Measure your existing tools carefully.

- Sketch a design with the right dimensions.

- Choose a strong material for durability.

- Use machines to cut and shape it.

- Test the fit and adjust if necessary.

Custom toolbit holders can make your work easier and more efficient. They match your needs perfectly!

Why should I consider custom holder dimensions?

Custom holder dimensions give a stronger grip and precise cutting. This leads to better results and fewer mistakes. Always choose what fits your tools best.

Best Practices for Selecting Toolbit Holder Dimensions

Key considerations for optimal performance. Tips for ensuring compatibility with lathe machines.Selecting the right toolbit holder dimensions is key for great results. Here are some important tips to help:

- Size Matters: Choose a holder that fits your lathe machine perfectly.

- Material Strength: Use holders made of durable metal to avoid breakage.

- Toolbit Compatibility: Ensure the toolbit matches the holder’s dimensions.

- Weight Balance: Lighter holders can improve control while working.

Following these tips will help you enjoy smoother and safer machining. Remember, a good toolbit holder can make a big difference!

What is important for selecting toolbit holder dimensions?

Consider size, strength, and compatibility of materials for best results.

Maintenance and Care for Toolbit Holders

Recommended maintenance practices to prolong holder life. Signs of wear and when to consider replacement.To keep your toolbit holders in great shape, practice regular maintenance. Clean them after each use. Check for dirt or chips. Store them in a safe place to avoid damage. Here are some signs that indicate it’s time for a replacement:

- Visible cracks or chips on the holder.

- Difficulty in securing the toolbit.

- Frequent adjustments needed during operation.

Taking these steps will help your metal lathe toolbit holders last longer.

How can I know when to replace a toolbit holder?

If you see cracks or a loose fit, it’s time for a new one. Regular checks can save you trouble down the road!

Safety Considerations When Using Toolbit Holders

Essential safety measures to follow. Importance of proper setup and adjustments.Using toolbit holders safely is very important. Always wear safety gear like goggles and gloves. Keep your workspace tidy to avoid accidents. Proper setup is key. Check that the toolbit is tight and aligned correctly. Adjust settings carefully for the best results.

- Wear protective equipment.

- Keep work area clean.

- Ensure correct alignment of toolbits.

- Make careful adjustments.

What should I do before using a toolbit holder?

Always inspect your toolbit holder and confirm all parts are secure before starting. This ensures your safety and helps achieve better work quality.

Conclusion

In summary, knowing metal lathe toolbit holder dimensions helps you choose the right tools for your projects. Proper dimensions ensure better fitting and performance. Start by measuring your lathe and selecting holders that match. For more detailed guidance, check tutorials or ask experts. This will sharpen your skills and make your work easier. Happy lathing!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Toolbit Holder Dimensions:Sure! Here are five related questions about metal lathe toolbit holder dimensions: 1. What is a toolbit holder? A toolbit holder holds the cutting tool in a lathe. It keeps it steady while we work. 2. Why are dimensions important? Dimensions matter because they tell us how big or small the holder should be. A good fit helps us work better. 3. How do I measure the holder? You can use a ruler or caliper to measure its length and width. Make sure to measure carefully. 4. Can I use any holder for my lathe? Not really! Each lathe needs a specific holder size to work correctly. 5. What happens if the holder is too big or small? If it’s too big or small, it won’t fit well. This can cause problems when cutting metal.

Sure! Please provide the question you’d like me to answer.

What Are The Standard Dimensions For Toolbit Holders Used In Metal Lathes?Toolbit holders for metal lathes usually come in sizes like 1/2 inch and 5/8 inch. They can also be 3/4 inch wide. These sizes fit the toolbits that help cut metal. It’s important to have the right size so the tools work correctly. Always check your machine’s guide for the best fit!

How Does The Size Of A Toolbit Holder Affect The Performance And Precision Of Machining Operations?The size of a toolbit holder matters a lot. A bigger holder can hold the tool more securely. This helps the tool work better and makes cuts smoother. If the holder is too small, it might wobble, causing mistakes. So, choosing the right size means your work will be neater and more accurate!

What Are The Common Materials Used For Manufacturing Toolbit Holders, And How Do Their Dimensions Vary?Toolbit holders are often made from strong materials like steel, aluminum, or plastic. Steel is tough and lasts a long time. Aluminum is lighter, making it easier to handle. The sizes of toolbit holders can change, depending on the tools they hold. Some are small for tiny tools, while others are big for larger tools.

How Do The Dimensions Of A Toolbit Holder Differ Between Standard And Specialized Lathe Applications?Standard lathe toolbit holders are usually a common size and shape. They fit many regular tools easily. Specialized toolbit holders are often different. They can be longer, shorter, or shaped for special tasks. This helps you make unique parts better.

What Are The Key Factors To Consider When Selecting A Toolbit Holder For A Specific Lathe Model?When choosing a toolbit holder for your lathe, pay attention to a few key factors. First, check the size of the holder to make sure it fits your lathe. Next, consider the type of work you plan to do, like cutting or shaping. Also, look for a holder that is easy to change and adjust. Finally, think about how strong and durable the holder needs to be for your projects.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Toolbit Holder Dimensions:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions about metal lathe toolbit holder dimensions: 1. What is a toolbit holder? A toolbit holder holds the cutting tool in a lathe. It keeps it steady while we work. 2. Why are dimensions important? Dimensions matter because they tell us how big or small the holder should be. A good fit helps us work better. 3. How do I measure the holder? You can use a ruler or caliper to measure its length and width. Make sure to measure carefully. 4. Can I use any holder for my lathe? Not really! Each lathe needs a specific holder size to work correctly. 5. What happens if the holder is too big or small? If it’s too big or small, it won’t fit well. This can cause problems when cutting metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Standard Dimensions For Toolbit Holders Used In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Toolbit holders for metal lathes usually come in sizes like 1/2 inch and 5/8 inch. They can also be 3/4 inch wide. These sizes fit the toolbits that help cut metal. It’s important to have the right size so the tools work correctly. Always check your machine’s guide for the best fit!”}},{“@type”: “Question”,”name”: “How Does The Size Of A Toolbit Holder Affect The Performance And Precision Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size of a toolbit holder matters a lot. A bigger holder can hold the tool more securely. This helps the tool work better and makes cuts smoother. If the holder is too small, it might wobble, causing mistakes. So, choosing the right size means your work will be neater and more accurate!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Manufacturing Toolbit Holders, And How Do Their Dimensions Vary?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Toolbit holders are often made from strong materials like steel, aluminum, or plastic. Steel is tough and lasts a long time. Aluminum is lighter, making it easier to handle. The sizes of toolbit holders can change, depending on the tools they hold. Some are small for tiny tools, while others are big for larger tools.”}},{“@type”: “Question”,”name”: “How Do The Dimensions Of A Toolbit Holder Differ Between Standard And Specialized Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Standard lathe toolbit holders are usually a common size and shape. They fit many regular tools easily. Specialized toolbit holders are often different. They can be longer, shorter, or shaped for special tasks. This helps you make unique parts better.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Toolbit Holder For A Specific Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a toolbit holder for your lathe, pay attention to a few key factors. First, check the size of the holder to make sure it fits your lathe. Next, consider the type of work you plan to do, like cutting or shaping. Also, look for a holder that is easy to change and adjust. Finally, think about how strong and durable the holder needs to be for your projects.”}}]}