Quick Summary:

A midi wood lathe is an essential, versatile tool for professionals. It offers precision and capability for intricate projects that larger lathes can’t handle as efficiently. It’s a smart investment for serious woodworkers seeking quality and control in their craft, proving its worth through consistent, reliable performance.

Midi Wood Lathe for Professionals: The Proven Essential for Precision and Power

Are you a professional woodworker looking to elevate your craft? Perhaps you’ve admired the intricate details and smooth finishes on turned projects and wondered how they’re achieved. Many think only massive, expensive machines can produce professional results, but that’s not always the case. The midi wood lathe is an often-underestimated powerhouse that combines precision, convenience, and surprisingly robust capabilities. It’s the secret weapon for countless professionals who need to tackle detailed work without the bulk of a full-sized lathe. Don’t worry if you’re new to this; we’ll guide you through why this machine is a must-have and how to make it work for you.

In this guide, we’ll break down what makes a midi wood lathe so valuable for professionals. We’ll explore its key features, discuss why it’s a smart investment, and help you understand how it can expand your creative horizons. Get ready to discover why this compact machine deserves a permanent spot in your workshop.

Why a Midi Lathe is Essential for Professionals

When you’re working on projects that demand fine detail, accuracy, and control, the right tools make all the difference. A midi wood lathe proves itself indispensable for professionals for several key reasons. It bridges the gap between hobby-grade machines and large industrial setups, offering a sweet spot of functionality and accessibility.

For professionals, time is money, and efficiency is paramount. A midi lathe excels here by being quick to set up, easy to move if needed, and perfectly suited for smaller, more intricate pieces that are often high-value items. Think of delicate bowls, intricate spindle work for furniture, tool handles, or decorative elements. These tasks often require a level of finesse that a larger lathe can make cumbersome.

Versatility in a Compact Package

One of the biggest advantages of a midi lathe is its surprising versatility. Despite its smaller size, most professional-grade midi lathes have powerful enough motors and sturdy construction to handle a wide range of turning tasks. They can often be fitted with accessories that expand their capabilities even further.

- Size Matters: Ideal for smaller workshops or for professionals who need to move their equipment.

- Precision Control: The shorter bed length and often variable speed controls allow for very precise adjustments and finer detail work.

- Variety of Projects: From small decorative items and pens to smaller bowls and spindles, a midi lathe can handle it all.

- Accessory Integration: Many midi lathes accept drill chucks, faceplates, and even some attachments like copy attachments or small routing jigs.

Accessibility and Cost-Effectiveness

While professional tools come with a professional price tag, midi lathes often represent a more accessible entry point into professional-grade equipment compared to their full-sized counterparts. This makes them a strategic investment, especially for smaller shops or those specializing in smaller, high-margin items.

Investing in a quality midi lathe can provide a professional with a reliable workhorse for specific tasks without the massive outlay required for a larger machine. This allows budgets to be stretched further, enabling investment in other essential tools or materials. It’s a smart financial decision that doesn’t compromise on quality or performance for targeted applications.

Ideal for Specialized Work

Many professional woodworkers don’t spend all their time turning massive dining table legs or enormous bowls. Often, the most profitable and distinguishing work involves smaller, more intricate pieces. This is where the midi lathe truly shines.

Consider a woodturner who specializes in artisanal pens, intricate chess pieces, small decorative boxes, or detailed jewelry. These items require extreme precision and a different set of skills than roughing out a large bowl. A midi lathe provides the control necessary for this fine detail work, allowing the woodworker to achieve superior results that stand out in the market.

Key Features to Look For in a Professional Midi Lathe

When selecting a midi wood lathe for professional use, you’re not just looking for any machine; you need one that is robust, reliable, and packed with features that support precision and efficiency. Not all midi lathes are created equal, and professionals need to pay attention to specific build qualities and functionalities.

Here are the crucial features to consider that will ensure your midi lathe is a true professional asset:

Motor Power and Speed Control

For professional work, a strong motor is crucial. You’ll want a motor that can handle sustained use and varying wood densities without bogging down. Look for machines with a minimum of 0.75 HP (horsepower), with 1 HP or more being ideal for demanding tasks. Variable speed control is non-negotiable for professionals.

- Horsepower (HP): Aim for at least 0.75 HP, preferably 1 HP or higher for continuous professional use.

- Variable Speed: Essential for controlling the cut based on wood type, tool sharpness, and desired finish. Look for a speed range that allows for both slow turning (for roughing) and faster turning (for finishing).

- Belt vs. Electronic Speed Change: Belt changes are common and reliable, but electronic speed control offers on-the-fly adjustments for maximum convenience and precision.

Bed Construction and Stability

The foundation of any lathe is its bed. For professional use, a sturdy, heavy cast-iron bed is paramount. This provides vibration damping, which is critical for achieving smooth finishes and precise cuts, especially when working with harder woods or at higher speeds.

A stable base, whether it’s integrated legs or a robust stand, is also vital. Any wobbling or vibration can translate into an uneven finish or even dangerous kickbacks. Professionals often bolt their lathes down to a workbench or a solid stand for maximum stability.

Swing and Distance Between Centers

These specs define the maximum size of the workpiece you can turn. For a midi lathe, the “swing” is the maximum diameter that can rotate over the bed, and the “distance between centers” is the maximum length of stock you can mount.

- Swing: Typically ranges from 10 to 16 inches for midi lathes. This is sufficient for many professional applications like smaller bowls, spindles, and detailed turnings.

- Distance Between Centers: Usually between 16 and 24 inches for midi lathes. This dictates the length of the workpiece you can turn.

While a midi lathe won’t turn massive platters, its limitations in swing and distance are often a feature for professionals who specialize in smaller, high-detail work. It forces precision and control.

Tool Rest System

The tool rest allows you to support your turning gouges and chisels at the correct angle to the workpiece. A professional midi lathe should have a robust and easily adjustable tool rest system. Look for:

- Solid Construction: The tool rest should be made of sturdy metal that won’t flex under pressure.

- Easy Adjustment: A quick-release lever or an indexing pin system allows for fast and accurate repositioning of the tool rest as your workpiece shape changes.

- Variety of Lengths: Having different lengths of tool rests available can be beneficial for different project types and tool sizes.

Tailstock and Headstock Features

The tailstock provides support at the outboard end of the workpiece, especially for longer pieces or when drilling. The headstock houses the drive mechanism and typically has a Morse taper for securely mounting accessories.

- Morse Taper: Standardized fittings (usually #1 or #2 Morse taper) ensure that accessories like drill chucks and live centers are held securely.

- Quill Travel: The tailstock quill should have sufficient travel to allow for centering drill bits or tenons.

- Offset Capability: Some professional midi lathes offer a tailstock that can be offset for eccentric turning (though this is less common on smaller midi models).

The headstock also houses the drive centers. A sturdy, well-balanced headstock is crucial for minimizing vibration.

Midi Wood Lathes vs. Full-Sized Lathes for Professionals

The choice between a midi wood lathe and a full-sized lathe often comes down to the specific needs and specialization of a professional woodturner. Each has distinct advantages that cater to different types of work and workshop environments.

Think of it like this: a full-sized lathe is a powerful truck, capable of hauling large loads and tackling tough, heavy-duty jobs. A midi lathe, on the other hand, is more like a precision sports car – agile, accurate, and perfect for detailed maneuvering and high-performance tasks where brute force isn’t the primary requirement.

Advantages of Midi Lathes for Professionals

As we’ve touched upon, the midi lathe excels in specific areas that often appeal to professionals:

- Space Efficiency: Midi lathes take up significantly less floor space, making them ideal for smaller workshops or for mobile setups.

- Portability: While still substantial, many midi lathes are lighter and can be more easily moved or repositioned than larger machines, which might be important for shops that rearrange frequently or for artisans participating in craft fairs.

- Cost-Effectiveness: Generally less expensive than their full-sized counterparts, allowing professionals to invest in other areas or add more specialized tools.

- Precision Detail Work: The shorter bed and often more responsive controls make them perfect for intricate turning, small bowls, pens, and decorative elements.

- Faster Setup: Quicker to get up and running for smaller jobs, improving workflow efficiency.

Advantages of Full-Sized Lathes for Professionals

Full-sized lathes are designed for different demands:

- Capacity: They can handle much larger and heavier workpieces – think large bowls, platters, table legs, and even segmented turning projects that require significant diameter and length.

- Power and Torque: Often equipped with more powerful motors that deliver higher torque, essential for roughing out large billets of wood or working with very dense hardwoods.

- Stability: Their sheer mass and robust construction inherently provide greater stability, reducing vibration even further for massive projects.

- Tooling Options: Many full-sized lathes can accommodate a wider range of specialized attachments and larger, heavier turning tools.

When to Choose Which

A professional turning a wide array of items, from small decorative pieces to larger functional items, might find a midi lathe is their primary workhorse for most of their day-to-day projects, supplemented by a larger lathe if needed for specific tasks. Woodturners specializing exclusively in very large bowls or furniture components would lean towards a full-sized lathe.

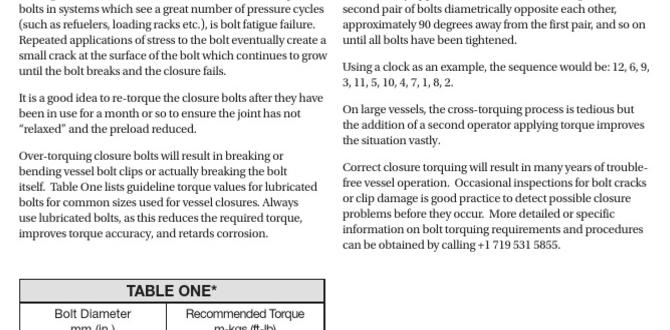

| Feature | Midi Wood Lathe (Professional) | Full-Sized Wood Lathe (Professional) |

|---|---|---|

| Typical Swing Diameter | 10 – 16 inches | 16+ inches (often 20-30+ inches) |

| Typical Distance Between Centers | 16 – 24 inches | 30+ inches (often 40-60+ inches) |

| Ideal For | Small bowls, pens, spindles, decorative items, intricate details, smaller workshops. | Large bowls, platters, furniture legs, large segmented pieces, heavy-duty stock removal. |

| Space Requirement | Compact | Large footprint |

| Portability | Moderate to easy | Difficult, often stationary |

| Cost | Generally lower | Significantly higher |

| Power Requirements | Typically 0.75 – 1.5 HP | Typically 1.5 HP and up (often 3-5 HP or more) |

Essential Accessories for Your Professional Midi Lathe

To get the most out of your midi wood lathe, investing in a few key accessories is crucial. These don’t just add convenience; they expand the capabilities of your machine and improve the quality and safety of your work. For a professional, the right tools mean efficiency and higher output.

Here are some must-have accessories:

Turning Tool Set

You can’t turn wood without turning tools! A professional set should include a variety of gouges and chisels designed for different tasks. High-speed steel (HSS) is the standard for a good reason – it holds an edge longer.

- Spindle Gouge: For shaping spindles, beads, and coves.

- Roughing Gouge: For removing waste stock and creating a round blank from a square one.

- Bowl Gouge: For shaping bowls and hollow forms. The shape and bevel will vary depending on the intended use (e.g., detailer vs. general purpose bowl gouge).

- Skew Chisel: For scraping cuts to create smooth surfaces, particularly on spindle work.

- Parting Tool: For cutting grooves and separating pieces.

- Scrapers: Flat scrapers for smoothing internal surfaces of bowls.

Tip for Professionals: Invest in quality tools and learn to sharpen them properly. Sharp tools cut better, safer, and produce a superior finish. Resources on proper sharpening techniques can be found at sites like Wood Magazine’s sharpening guide.

Faceplates and Chuck

While the lathe comes with a basic drive spur, you’ll quickly need more ways to mount your work.

- Faceplate: A flat metal disc that screws onto the lathe’s spindle thread. You can then screw or bolt your workpiece directly to the faceplate, ideal for larger, flatter items or workpieces that can’t be held by a spur or chuck.

- Wood Lathe Chuck: This is arguably the most important accessory for many professionals. A chuck has jaws that expand or contract to grip the workpiece securely. This allows for turning bowls and hollow forms from both ends, turning between centers initially, and then chucking for hollowing. Look for a quality 3- or 4-jaw scroll chuck.

Live Center and Drill Chuck

These accessories are mounted on the tailstock.

- Live Center: This center rotates with the workpiece, reducing friction and heat buildup compared to a dead center, which is stationary. It’s essential for supporting longer pieces that are mounted between centers.

- Drill Chuck: Mounts into the tailstock quill and holds drill bits. This is crucial for drilling into the end of your turning, such as creating a mortise for a tenon to fit into a lid or for drilling for hardware.

Tool Rest Extensions and Stands

While the standard tool rest is often adequate, professional woodturners may benefit from:

- Longer Tool Rests: Useful for supporting larger tools or for extra stability when working on bigger pieces (within the capacity of the midi lathe).

- Curved Tool Rests: Shaped to better conform to the curve of hollow forms or bowls.

- Robust Mobile Stand: If your midi lathe isn’t mounted to a bench, a heavy-duty, stable stand (preferably with casters) is essential for both stability and maneuverability. Many professional shops benefit from being able to move their primary lathe to optimize workflow or clean the shop.

A well-equipped midi lathe setup allows professionals to tackle a wider range of projects with greater efficiency and finesse. Prioritize accessories that directly address the types of work you do most often.

<