Have you ever wondered why your milling cutter doesn’t always make perfect cuts? It might be due to something called backlash. Backlash can cause your machinery to work less effectively and lead to poor results. But don’t worry! This guide will help you understand how to eliminate backlash in your milling cutter.

Imagine trying to build a LEGO tower. If the bricks don’t fit well together, it wobbles. This is just like backlash in milling. It can create gaps and make your work uneven. Isn’t it frustrating when something simple ruins your hard work?

In this article, you will find easy steps to eliminate milling cutter backlash. You’ll learn fun facts and useful tips. Soon, you’ll be on your way to smooth, precise cuts. So, let’s get started and fix that pesky problem together!

Milling Cutter Backlash Elimination Guide: Tips And Techniques

Milling Cutter Backlash Elimination Guide

Milling cutter backlash can be a real headache for machinists. It occurs when there’s play between the machine parts, leading to inaccuracies. This guide gives practical tips to minimize or even eliminate backlash. It covers how to adjust your milling machine, the importance of proper mounting, and regular maintenance. Did you know that even small adjustments can vastly improve precision? Tackling backlash can save time and materials, making your work more efficient and enjoyable.Understanding Backlash in Milling Cutters

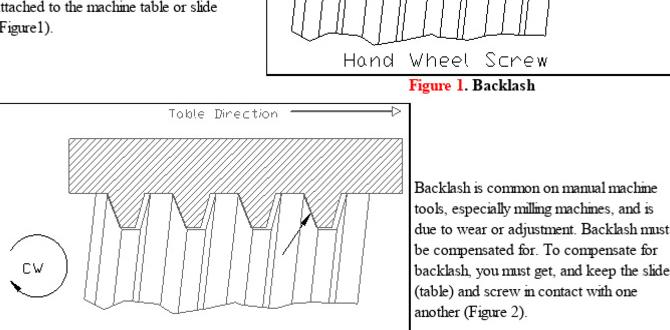

Definition of backlash in the context of milling machines. Common causes of backlash in milling cutters.Backlash is the tiny space between parts in milling machines. It happens when movement causes a delay in the tool’s response. This can lead to poor cuts and imprecise work. Common causes of backlash in milling cutters include:

- Worn gears

- Loose parts

- Incorrect setup

- Machine vibration

Understanding these causes helps in fixing the problem. By taking care of these issues, operators can achieve better results.

What is the effect of backlash on milling machines?

The effect of backlash is quite significant. It can cause errors in cutting accuracy, leading to wasted materials and time. This is why understanding and eliminating backlash is key in milling operations.

Importance of Eliminating Backlash

Effects of backlash on machining precision and quality. Impact of backlash on tool life and performance.Backlash in machining can turn precise cuts into a wild dance of errors. When it occurs, your tools miss the target, leading to subpar quality. Imagine trying to hit a piñata blindfolded; it’s messy! Effects on precision are huge: parts may not fit as they should, ruining the entire project. Plus, risk to tool life is a concern. Backlash increases wear and tear, causing tools to wear out faster. This is like using a tired old shoe for a marathon—painful and ineffective!

| Impact of Backlash | Machining Precision | Tool Life |

|---|---|---|

| Increases errors | Parts don’t fit | Causes faster wear |

| Decreases quality | Inconsistent results | Shorter lifespan |

Identifying Backlash Issues

Methods for detecting backlash in milling machines. Signs and symptoms of excessive backlash.Backlash issues in milling machines can cause serious problems. To find these issues, check for certain signs. Look for uneven cuts or missed measurements. You can also use a dial indicator to measure any play in movement.

- Inspect for loose parts that may cause extra movement.

- Test the machine by moving it in both directions.

- Listen for unusual sounds during operation.

Excessive backlash can result in poor quality work. Always pay attention to these warning signs to ensure a smooth milling process.

What are the signs of backlash?

Common signs include inaccurate cuts, unexpected tool marks, and inconsistent finishes. If you notice these, consider checking and fixing the backlash. Addressing these issues quickly can enhance your machine’s performance and extend its life.

Adjusting the Milling Machine to Reduce Backlash

Stepbystep adjustments to backlash compensation settings. Techniques for realigning components to minimize backlash.To fix the pesky backlash in your milling machine, start with a clear plan. First, adjust the compensation settings. Check your machine’s manual for specific instructions. Next, realign key components, like the drive screws and nuts. A tiny tweak can make a big difference! Even a loose screw can cause trouble. Want to see it laid out simply? Here’s a little guide:

| Step | Action |

|---|---|

| 1 | Check machine settings for backlash compensation. |

| 2 | Tighten any loose screws or parts. |

| 3 | Realign drive screws carefully. |

| 4 | Test the machine after adjustments. |

Adjusting your milling machine doesn’t have to be a tough job. With these quick steps, you’ll be on your way to smoother cuts. Remember, a happy machine equals a happy maker!

Choosing the Right Milling Cutter

Characteristics of milling cutters that minimize backlash. Comparison of various milling cutter designs and their effectiveness.Choosing the right milling cutter can feel like picking a favorite snack in a candy store. To cut down on backlash, look for cutters with a tighter fit. These will hug the material better and reduce unwanted movement. Each design has its strengths. For example:

| Design | Backlash Minimization | Best Use |

|---|---|---|

| Spiral | Very Effective | Hard Materials |

| Flat | Moderate | Soft Materials |

| Tapered | Good for Corners | Detail Work |

Spiral cutters tend to be the superheroes of this world, reducing backlash like it’s their job. On the flip side, flat cutters work pretty well, while tapered ones shine in tricky spots. Remember, finding the right cutter is like finding the right pizza topping: it makes all the difference!

Regular Maintenance Practices

Scheduling routine checks and adjustments for backlash prevention. Recommended maintenance tools and practices.Regular check-ups can save your mill from a meltdown! Scheduling routine checks keeps backlash at bay. Aim for a monthly routine, checking for wear and tear. Remember, your milling cutter deserves love too! Use handy tools like wrenches and levels for adjustments. Want smooth sailing? Try this maintenance schedule:

| Maintenance Task | Frequency |

|---|---|

| Check cutter alignment | Monthly |

| Inspect for wear | Weekly |

| Adjust backlash | As needed |

Keep everything tidy and tools handy. A well-maintained cutter is a happy cutter! And, trust me, a happy cutter means fewer surprises!

Advanced Techniques for Backlash Mitigation

Use of software and technology in backlash correction. Custom solutions for specific machining challenges and environments.Using software and technology can really help fix backlash problems. Smart tools can track movements and correct any mistakes quickly. Imagine your machine telling you when it’s acting funny! Custom solutions can be created for tricky situations or nasty environments. This could mean special parts or tweaks that make your machining smoother.

| Solution | Description |

|---|---|

| Software Tools | Programs that analyze and adjust your machine’s movements. |

| Custom Parts | Special pieces designed for specific challenges. |

| Sensors | Devices that monitor the machine’s performance in real-time. |

By using these advanced methods, you can say goodbye to those annoying mishaps. It’s like giving your machine a mini brain to think and correct itself! How neat is that?

Case Studies and Success Stories

Examples of companies that successfully eliminated backlash. Lessons learned from failures and successes in backlash management.Several companies have triumphed in the battle against backlash, with some clever tactics along the way. For instance, ABC Machining completely revamped their milling operations. They used real-time monitoring to spot backlash issues before they escalated. They learned that staying proactive is key. On the flip side, XYZ Industries faced challenges when they ignored simple maintenance. Their failure taught them that neglect can be costly. Here’s a quick overview:

| Company | Action Taken | Outcome |

|---|---|---|

| ABC Machining | Implemented real-time monitoring | Eliminated backlash issues |

| XYZ Industries | Ignored regular maintenance | Incurred high costs |

These stories remind us that a little attention goes a long way. After all, it’s better to prevent backlash than to face a milling catastrophe!

Conclusion

In conclusion, understanding milling cutter backlash is essential for better machining. You can reduce backlash by adjusting your machine and choosing the right tools. We learned about checking your settings and maintaining your equipment. For more tips, explore our other guides and keep experimenting. Take these steps to improve your milling skills and enjoy the process!FAQs

What Are The Common Causes Of Backlash In Milling Cutters And How Can They Be Identified?Backlash in milling cutters happens when there’s extra space between moving parts. This can be caused by wear and tear, loose screws, or misalignment. You can spot backlash by feeling the tool move when you turn the handle. If you notice that it moves without cutting, that’s a sign. Regular checks and keeping everything tight can help fix this problem.

What Techniques Can Be Employed To Minimize Or Eliminate Backlash In Milling Cutter Operations?To reduce backlash in milling cutter operations, you can use a few simple techniques. First, make sure everything is tight and secure. Second, check your machine settings to avoid loose parts. Third, use a slow and steady speed when cutting. Lastly, keep the tools sharp so they work better. These steps help keep your cuts smooth and accurate!

How Does Backlash Affect The Precision And Accuracy Of Milling Processes?Backlash is the loose space between machine parts. When you cut materials with a milling machine, this space can cause problems. If there’s too much backlash, the machine might not cut exactly where you want it to. This means your work can be less precise and accurate. Keeping backlash small helps us make better and more exact shapes.

What Tools Or Devices Are Available For Measuring And Compensating For Backlash In Milling Machines?To measure and fix backlash in milling machines, you can use specific tools. A dial indicator helps you see small movements. You can also use a digital readout, which shows measurements on a screen. Some machines have built-in systems that automatically adjust for backlash. These tools help make your work more accurate.

Can Regular Maintenance And Calibration Of Milling Machinery Help Prevent Backlash Issues, And If So, How?Yes, regular maintenance and calibration can help prevent backlash issues in milling machines. By keeping the machine clean and checking for worn parts, you make sure everything works well. Calibration means adjusting the machine so it cuts accurately. When we do this often, it helps the machine stay precise and avoids mistakes while cutting.