Have you ever wondered how to make perfect cuts with a milling cutter? Many people face issues with burrs when cutting dry. It can be frustrating, especially if you want clean edges and smooth surfaces.

Imagine trying to build something amazing. You want it to look great, but those pesky burrs get in the way. They ruin your hard work. This is where milling cutter burr control comes into play. It can change everything!

Here’s a surprising fact: the right techniques can help you reduce burrs significantly. Using dry cutting methods might seem tricky, but with the right tips and tricks, you can master it. So, how do you control those burrs and improve your results? Let’s explore this exciting topic together!

Milling Cutter Burr Control In Dry Cutting Techniques

Milling Cutter Burr Control in Dry Cutting

Milling cutters can create stubborn burrs during dry cutting, making surfaces rough. Proper burr control is crucial for a smooth finish. Using high-quality tools helps reduce these imperfections. Did you know that burrs can even impact the performance of machinery? Choosing the right speed and feed rate also plays a big part. This way, you can keep production efficient and your workpiece looking great. Curious to learn more? Fine-tuning your technique can lead to impressive results!Understanding Burr Formation

Definition and types of burrs in machining. Factors influencing burr formation in dry cutting.Burrs are tiny rough edges that form on metal after cutting. There are different types of burrs, like teardrop, rollover, and fractured burrs. Each type affects the finish of the metal part. In dry cutting, burr formation is influenced by:

- Material type

- Cutting speed

- Tool sharpness

- Temperature

Understanding these factors helps to control burr formation and improve product quality.

What are burrs in machining?

Burrs are rough edges that form on materials during cutting processes.

Importance of Burr Control

Impact on product quality and surface finish. Economic implications of burr removal processes.Burr control is important because it affects both the quality of products and how they look. If burrs are left on a product, it can make it rough and unattractive. On the economic side, removing burrs takes time and resources, which can add costs. Efficient burr control can save money and improve quality.

- Better product quality: Smooth surfaces are essential for customer satisfaction.

- Cost savings: Effective burr removal reduces time and labor expenses.

Why is burr control vital in milling?

Good burr control leads to higher quality products and reduced costs. This can improve your business’s reputation and profits.

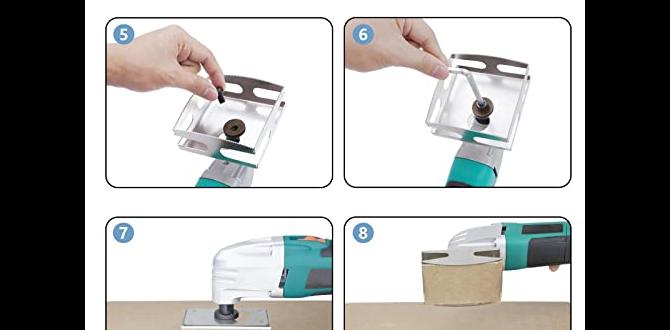

Techniques for Burr Control in Dry Cutting

Use of appropriate milling cutter geometry. Optimization of cutting parameters.Using the right milling cutter geometry is the first step in burr control in dry cutting. This means choosing a cutter tip that suits the type of material. For example, a sharp angle can reduce burrs. Next, optimizing cutting parameters is crucial. Here are two key factors:

- Use the right speed. A slower speed may help limit burrs.

- Adjust feed rate. A smoother feed can lead to cleaner cuts.

By focusing on these techniques, you can improve your dry cutting results.

What is the best milling cutter geometry for burr control?

The best geometry depends on the material. **Sharp angles** often create fewer burrs while also maintaining a smooth finish.

Why adjust cutting parameters?

Adjusting cutting parameters helps you achieve better control. **Proper speed and feed rates** can greatly reduce burr formation.

Material Considerations

Effects of workpiece material on burr formation. Best materials for reducing burrs in dry cutting.Choosing the right material can make a big difference in burr formation during dry cutting. Harder materials tend to create more burrs. It’s like trying to slice a loaf of bread with a dull knife—messy and annoying! On the other hand, softer materials can reduce burrs, making work smoother. Metals like aluminum work wonders. They are easier to cut and lead to fewer burrs. It’s like buttering toast instead of hacking at it!

| Material | Burr Formation |

|---|---|

| Aluminum | Low |

| Steel | Moderate |

| Stainless Steel | High |

The right choice helps keep things tidy! Isn’t it nice to celebrate clean cuts and fewer burrs? Let’s cut down the chaos in metalworking!

Role of Cutting Fluids and Lubricants

Benefits of cutting fluids in mitigating burrs. Alternatives to traditional lubricants in dry cutting.Cutting fluids play a big role in keeping things smooth. They help reduce burrs and offer a clean cut. Think of them as the superheroes of milling; they swoop in to save the day! When cutting dry, alternatives like air or polymer-based solutions can step up. These options are not only eco-friendly, but they also reduce clutter on your work surface. Who needs a mess, right? Below is a quick comparison:

| Type of Lubricant | Benefits |

|---|---|

| Traditional Cutting Fluids | Reduces heat and minimizes burrs. |

| Air | No waste and easy clean-up! |

| Polymer Solutions | Eco-friendly with good lubrication. |

So, whether you use old-school fluids or new-age options, keeping burrs in check is key for a clean finish!

Advanced Technologies for Burr Prevention

Innovations in milling cutter design. Automation and control technologies for burr management.New ideas in milling cutter design are changing the game for burr prevention. Some cutters now have fancy shapes and materials that make them work better and reduce burrs. It’s like giving them a high-tech makeover! Plus, automation helps manage burrs by using smart technology. This means machines can control the cutting process more closely. Less burrs mean less cleanup, and that saves time—who doesn’t want that?

| Technology | Benefit |

|---|---|

| Innovative Cutter Designs | Fewer burrs, better finish |

| Automation Control | Consistent quality, less waste |

With these advancements, burr control becomes a piece of cake—or should we say a piece of non-burr pie?

Case Studies and Best Practices

Realworld examples of effective burr control. Lessons learned from industry applications.Effective burr control is essential in many industries. Companies have learned valuable lessons from case studies. For instance, a leading manufacturer improved quality by adjusting their milling cutter burr control settings. They saw a 30% drop in burr size. Another firm reported fewer defects after using specialized tools.

- Regular tool inspections can prevent burr formation.

- Using sharp cutters reduces burrs significantly.

- Training operators on proper techniques is vital.

These examples show that careful planning and training can lead to better results.

What are real-world examples of effective burr control?

One example is a company that improved their burr control by 30% when they optimized their milling process. Another example involves a manufacturer that reduced defects by enhancing operator training.

Future Trends in Burr Control Techniques

Emerging technologies and methodologies in dry cutting. Predictions for the future of milling cutter design and burr management.New ideas in burr control are changing how we think about milling cutters. Robotics and smart sensors will play a big role. These tools can help machines learn and adjust to reduce burrs even better. In the future, we might see milling cutters designed specifically for dry cutting, using lighter materials for less heat. This means less burr formation and better results. The focus will be on keeping cuts clean and precise.

What are some new technologies in burr control?

Emerging technologies include smart sensors and robotic systems that adapt during the cutting process.Future predictions for milling cutter design:

- Lightweight materials will reduce heat build-up.

- Advanced coatings will minimize friction and burrs.

- Intelligent cutters will use data to optimize performance.

Conclusion

In summary, controlling burrs with milling cutters during dry cutting is key for smooth edges. You can minimize burrs by choosing the right cutter and adjusting your speed. Remember to check your tools often. For more tips and techniques, don’t hesitate to explore further resources. Let’s keep learning and improving our skills together!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Burr Control In Dry Cutting:Milling cutter burr control in dry cutting is about making clean cuts without rough edges. When we cut metal or wood, tiny bits can stick out, known as burrs. To manage these, we can choose the right tools and keep them sharp. We also need to adjust the speed and pressure while cutting. This way, we get smoother pieces without extra pieces sticking out.

Sure! Please ask your question, and I’ll be happy to help.

What Are The Primary Factors That Influence Burr Formation During Dry Milling Processes?Burrs are tiny bits of metal that can form when machines cut materials. The main things that cause burrs are the speed of the cutting tool, how hard the material is, and how sharp the tool is. If you go too fast or use a dull tool, you get more burrs. Keeping a careful eye on these things can help us make cleaner cuts.

How Do Different Milling Cutter Geometries Impact Burr Control And Overall Cutting Performance?Different milling cutter shapes can change how well we control burrs and how effectively they cut. If a cutter has sharp edges, it makes cleaner cuts and fewer burrs. A rounded edge might create more burrs but can cut smoother surfaces. Choosing the right shape helps us get better results when we work with materials.

What Techniques Or Technologies Can Be Implemented To Minimize Burr Formation When Using Dry Cutting Methods?To reduce burrs when cutting dry, you can try a few things. First, use sharp tools because they cut better and create fewer rough edges. You can also adjust the cutting speed to find the best setting that limits burrs. Lastly, keep the material steady while cutting to help control the cut. By doing these things, you can have smoother edges.

How Does The Choice Of Cutting Parameters, Such As Speed And Feed Rate, Affect Burr Size And Distribution In Dry Milling?When you cut metal, the speed and feed rate matter a lot. If you go faster, the burrs can be smaller and spread out. A slower feed rate makes bigger burrs that are closer together. So, by changing these settings, you can control the size and placement of burrs. This helps make your work look cleaner and smoother!

What Role Does Tool Material Play In Enhancing Burr Control During Dry Milling Operations?The tool material is very important for burr control when we do dry milling. If you use hard tools, they create smoother edges on the materials. This helps reduce little bits called burrs that stick out. Good tool materials last longer, so you do not have to change them often. Overall, choosing the right material keeps our work neat and clean.