Have you ever wondered why some tools cut through metal easily while others struggle? The secret often lies in the milling cutter carbide grade selection. Choosing the right carbide grade can make all the difference in your project. It can mean the difference between a smooth finish and a frustrating mess.

Imagine you’re in a workshop, ready to take on your next big project. You grab your tools, but which milling cutter should you use? Not all cutters are created equal. Some are perfect for certain materials, while others are better for different tasks. This choice shapes how crisp your edges look and how long your tools last.

Did you know that using the wrong carbide grade can lead to tool wear or poor performance? Understanding how to select the right milling cutter can save time and money. So, let’s dive into the world of carbide grades and discover what makes each one unique. Your next project will thank you for it!

Milling Cutter Carbide Grade Selection: A Comprehensive Guide

Choosing the right carbide grade for milling cutters is crucial for success in machining tasks. Different carbide grades provide various hardness levels and wear resistance. This choice affects tool longevity and performance. For example, more demanding materials may require tougher grades to avoid rapid wear. Have you ever noticed how dull tools create waste? Picking the right grade can save time and money. Understand the specific needs and you can optimize your machining projects effectively.

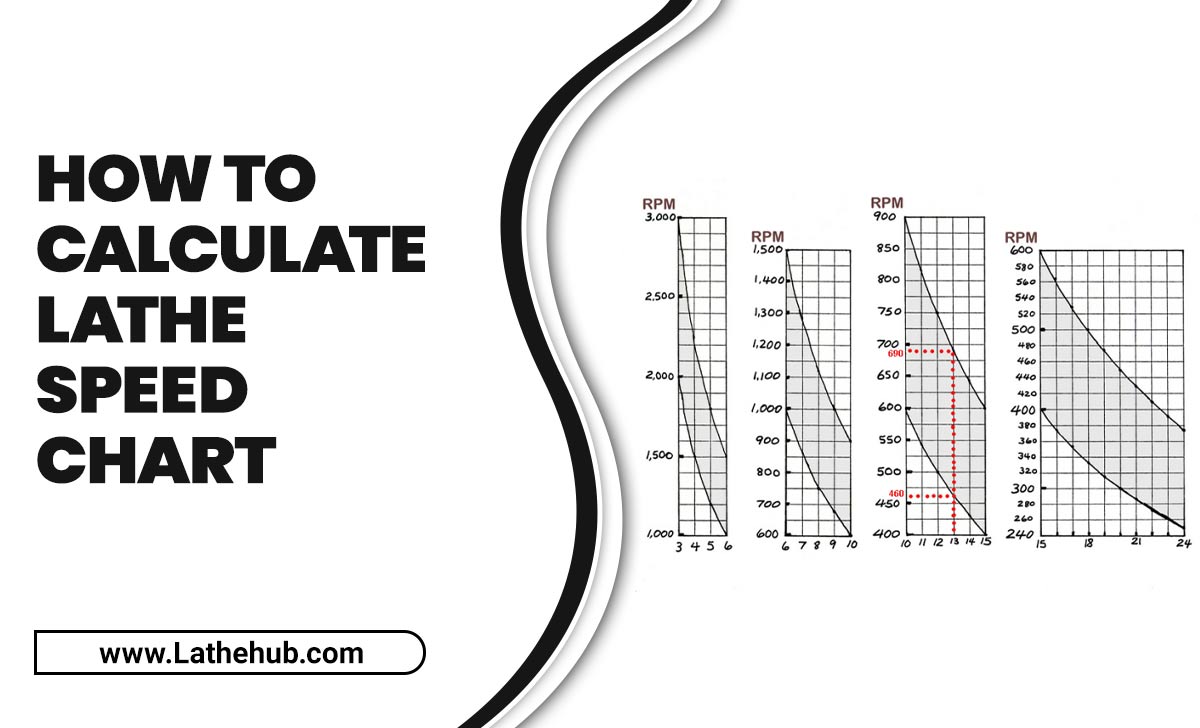

Factors Influencing Carbide Grade Selection

Material type and hardness considerations. Cutting speed and feed rate requirements.

Choosing the right carbide grade isn’t just a game of luck! Two main things to think about are the type of material and its hardness. Softer materials might feel like butter, but harder ones can be like a rock. You’ll need to adjust cutting speeds and feed rates based on these factors. For faster jobs, crank up the speed. For tougher materials, take it slow. Remember, a super-fast cutter on hard steel is like a blender on ice—just messy!

| Material Type | Hardness Level | Speed Recommendation | Feed Rate |

|---|---|---|---|

| Aluminum | Soft | High | Fast |

| Steel | Medium | Medium | Moderate |

| Titanium | Hard | Low | Slow |

So, whether you’re making furniture or rocket parts, pick wisely! Balance your selections for fantastic results. Remember, a little humor helps, but don’t forget the facts!

Common Carbide Grades and Their Applications

Description of popular carbide grades (e.g., C2, C5, C6). Suitable applications for each grade.

Carbide grades are important for choosing the right tools. Here are some popular ones:

- C2: Great for general-purpose work. It is tough and can handle many materials.

- C5: This grade is tougher and works well on harder materials. It’s perfect for steel and stainless steel.

- C6: This grade is best for super hard materials. Use it for high-speed machining.

Choosing the right grade helps make the job easier and better!

What are common carbide grades used for?

Common carbide grades are C2, C5, and C6. Each is used for different materials and tasks.

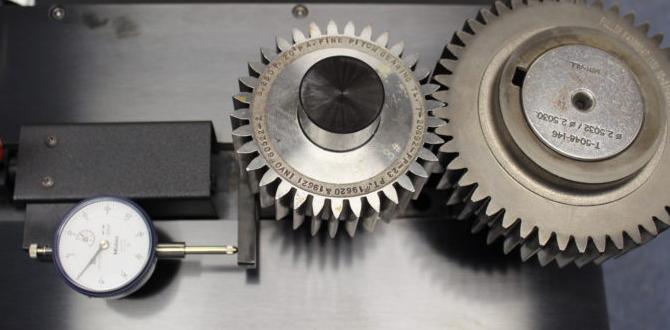

Evaluating Tool Geometry and Design

Importance of tool geometry in machining performance. How design influences grade selection.

Tool geometry plays a key role in how well machines cut materials. The shape and angles of the cutting tool directly affect its performance. A good design helps choose the right carbide grade. For example, sharper edges can cut through tough materials more easily. On the other hand, wider angles may work better for softer surfaces. Understanding these factors can improve machining results.

Why is tool geometry so important in machining?

The right tool geometry can lead to better cutting efficiency, which means faster operations and less wear on tools. Adjusting the design of the tool can help select the correct carbide grade, improving your overall work.

How does design influence grade selection?

- Shapes impact performance

- Angles determine cutting ability

- Materials affect durability

Cost vs. Performance Considerations

Analysis of costeffectiveness in carbide grade selection. Balancing performance and budget constraints.

Selecting a carbide grade for milling cutters means weighing cost against performance. You want tools that work well but don’t break the bank. Finding the right balance is key. Here are some points to consider:

- Budget Limits: Know what you can spend.

- Performance Needs: Choose a cutter that lasts and cuts well.

- Long-Term Value: Sometimes, paying more now saves money later.

In many cases, investing in quality leads to better results. Remember, performance is important, but staying within budget is just as crucial.

How do you balance cost and performance in carbide grade selection?

Balance cost and performance by considering your specific needs. Determine how often you use the cutters and the materials they will cut. This way, you can pick a grade that performs well without overspending.

Recommendations for Specific Industries

Selecting grades for automotive, aerospace, and manufacturing. Industryspecific considerations and standards.

Choosing the right carbide grade for milling cutters is crucial, especially in industries like automotive, aerospace, and manufacturing. For automotive, a grade that balances toughness and wear resistance is vital due to high-speed operations. Aerospace requires grades that can handle extreme conditions and tight tolerances. In manufacturing, flexibility and cost-effectiveness are key. Remember, using the right grade can save time and money—it’s like finding the right tool for the job, or a chef using the perfect knife!

| Industry | Recommended Grade Features |

|---|---|

| Automotive | Toughness & wear resistance |

| Aerospace | High durability & precision |

| Manufacturing | Flexibility & cost-effectiveness |

Maintenance and Care for Carbide Cutters

Best practices for prolonging tool life. Tips for safe handling and maintenance.

Taking good care of carbide cutters can save you money and headaches. Here are some tips to make your tools last longer. First, always clean your cutters after use. A little dirt can cause big problems! Second, store them safely in a dry place. Keeping them safe from bumps helps avoid damages. Did you know that proper storage can extend tool life by up to 30%? Lastly, always handle them with care. A slip could mean a trip to the repair shop, and nobody likes that. Follow these practices, and your cutters will thank you!

| Best Practices for Tool Care | Tips for Safe Handling |

|---|---|

| Clean after every use | Always hold with both hands |

| Store in a dry place | Avoid dropping or knocking |

| Inspect regularly for wear | Wear safety gloves and goggles |

Future Trends in Carbide Grade Development

Innovations in carbide materials and technology. Predictions for future grade advancements and applications.

Carbide materials are changing fast and will keep getting better! New types of carbide are popping up, making tools stronger and sharper. Imagine tools that last longer than your favorite pair of sneakers! Experts predict that future grades will focus on better heat and wear resistance, leading to smoother cuts and happier workers. Get ready for some cool applications, like cutting through tougher materials while sipping your coffee—now that’s multitasking!

| Innovation | Future Grade Advancement | Application |

|---|---|---|

| New carbide blends | Increased durability | Heavy machining |

| Advanced coatings | Better cutting performance | Precision engineering |

Conclusion

In conclusion, choosing the right carbide grade for milling cutters is crucial for your projects. Remember to consider factors like material and cutting conditions. This will help you achieve better results. Don’t hesitate to experiment with different grades to find what works best for you. For more information, check out guides and resources on carbide milling cutters. Happy cutting!

FAQs

What Factors Should Be Considered When Selecting The Appropriate Carbide Grade For A Specific Milling Cutter Application?

When choosing a carbide grade for a milling cutter, you should think about the material you’re cutting. Harder materials need tougher carbide grades. You also need to consider the cutting speed. Faster speeds can require a different grade. Lastly, think about how much you want the tool to last before needing a replacement.

How Do Different Carbide Grades Impact The Wear Resistance And Longevity Of Milling Cutters In Various Materials?

Carbide grades tell us how strong and tough the milling cutters are. Stronger grades resist wear better and last longer. If you cut harder materials, you need a tougher carbide. A good carbide can help you finish your work faster and buy fewer new cutters.

What Are The Advantages And Disadvantages Of Using Polycrystalline Diamond (Pcd) Versus Carbide Grades For Milling Applications?

Polycrystalline diamond (PCD) tools last longer than carbide tools, which is great. They cut smoothly, making jobs quicker and easier. But PCD tools are more expensive and can chip if you use them on hard materials. Carbide tools are cheaper and tougher, but they wear out faster. So, it depends on what you need for your work!

How Does The Hardness Of The Workpiece Material Influence The Choice Of Carbide Grade For Milling Cutters?

The hardness of the workpiece material affects our choice of carbide grade for milling cutters. Harder materials need tougher carbide grades. This means the cutters can handle more stress without breaking. If the material is soft, we can use a less tough grade. This helps us cut better and saves money.

What Role Does Coating Technology Play In Enhancing The Performance Of Carbide Milling Cutters, And Which Grades Benefit The Most From Coatings?

Coating technology helps carbide milling cutters work better and last longer. The coatings make the cutters stronger and reduce friction. This means they can cut faster and handle tough materials. Grades that are softer or made from special metals benefit the most from these coatings. They get improved performance and can last through more jobs.