Have you ever wondered how factories make perfect shapes out of metal? One tool that helps in this process is called a milling cutter. But did you know there’s a special device that measures how thick the chips are when cutting? It’s called a milling cutter chip thickness analyzer. This tool plays a crucial role in making sure everything runs smoothly.

Imagine a worker at a busy factory. They use a milling cutter to slice through metal. But what if the chips that come off are too thick or too thin? That could mess up the entire job! With the milling cutter chip thickness analyzer, workers can easily check the size of those chips. This ensures they achieve the best results, without wasting time or materials.

Fun fact: in some factories, using this analyzer can save thousands of dollars each month! This device is not just important—it is also a money-saver. Curious to learn more about how this amazing tool works? Let’s dive in!

Milling Cutter Chip Thickness Analyzer: Understanding Its Importance

Milling Cutter Chip Thickness Analyzer

The milling cutter chip thickness analyzer plays a vital role in manufacturing. It measures the thickness of chips created during milling. This helps in optimizing cutting conditions and improving product quality. Did you know that precise measurements can reduce waste and save costs? By understanding chip thickness, manufacturers can also enhance tool life and performance. Overall, using this analyzer can lead to more efficient and effective milling operations. Isn’t it amazing how a small tool can make such a big difference?Understanding Chip Thickness in Milling

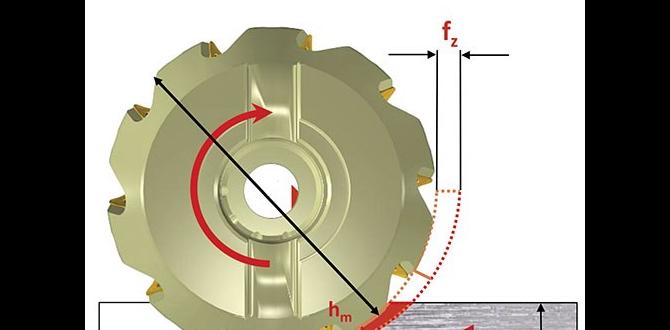

Definition of chip thickness in milling processes. Importance of chip thickness for machining efficiency and surface quality.Chip thickness in milling is simply the size of the slice taken off a material during cutting. Think of it as the thickness of a cookie when you take a bite—too thick, and you struggle; too thin, and it disappears! Chip thickness is vital for good machining efficiency and surface quality. If it’s just right, machines work smoother and leave a better finish. A well-balanced chip means quicker cuts without ruining your masterpiece.

| Factor | Impact on Efficiency | Impact on Surface Quality |

|---|---|---|

| Thin Chips | Faster cutting, less strain | Rough finish |

| Thick Chips | Slower, more power needed | Smoother finish |

Getting chip thickness right can lead to the ideal balance. Remember, in milling, a happy machine makes for a happy craftsman!

The Role of Chip Thickness Analyzers in Precision Engineering

Explanation of what a chip thickness analyzer is and how it works. Benefits of using chip thickness analyzers for manufacturers.A chip thickness analyzer is a smart tool that measures how thick the chips are when materials are cut. It helps engineers figure out if everything is going smoothly during their work. By using this handy device, manufacturers can see where they can improve. It can save time and money while ensuring higher quality.

Think of it like a magic ruler for your machine! With it, companies can make better products and reduce waste. Less waste means more money saved—that’s a win-win! It’s important in precision engineering and keeps everything running like a well-oiled machine.

| Benefits | Description |

|---|---|

| Improved Quality | Ensures precise cuts and better end products. |

| Cost Efficiency | Reduces material waste and lowers production costs. |

| Time Savings | Speeds up the manufacturing process. |

Key Features to Look for in a Chip Thickness Analyzer

Essential specifications and features for effective measurement. Comparison of manual vs. automated chip thickness analyzers.When choosing a chip thickness analyzer, consider these key features:

- Accuracy: Ensure it gives precise measurements for the best results.

- User-Friendly: Look for easy-to-use controls and displays.

- Portability: A lightweight design helps you move it around easily.

- Data Storage: Great models save measurements for later review.

There are two main types of analyzers:

- Manual: These require hands-on effort. Users measure thickness directly.

- Automated: These machines do the work for you, making it faster and easier.

In general, automated options save time and reduce human error. Make sure to pick one that fits your needs!

What features should a thickness analyzer have?

Look for features like accuracy, ease of use, and data storage. A good analyzer helps you get the best measurements!

Application of Chip Thickness Analysis in Different Industries

Case studies showcasing the application of chip thickness analyzers in automotive, aerospace, and healthcare industries. Impact of chip thickness measurement on product quality and production efficiency.Chip thickness analysis plays a vital role in many industries. For example, in the automotive sector, it improves engine components, making sure they fit perfectly. In aerospace, it helps create parts that can withstand high speeds, ensuring safety for pilots. The healthcare industry benefits too, as precision in surgical tools leads to better patient outcomes. Accurate measurements boost product quality and production efficiency significantly.

| Industry | Impact |

|---|---|

| Automotive | Better engine performance |

| Aerospace | Increased safety standards |

| Healthcare | Improved surgery results |

These industries show how chip thickness measurement can be a game-changer. It’s like giving your products a designer outfit—perfect fit and all themed for success!

Integrating Chip Thickness Analyzers with Modern Manufacturing Technologies

Compatibility with CNC machines and smart manufacturing systems. Data analytics and IoT in optimizing milling processes.Modern manufacturing is changing faster than a kid running to the ice cream truck! Chip thickness analyzers are fitting perfectly with CNC machines and smart systems. These tools help keep things running smoothly, like butter on hot toast. By using data analytics and IoT technology, manufacturers can collect important information to improve milling processes. This means they can cut costs and time while creating top-quality products. What’s better? It’s like finding a hidden cheat code for efficiency!

| Technology | Benefit |

|---|---|

| CNC Machines | Precise control and consistency |

| Data Analytics | Insights for smarter decisions |

| IoT | Real-time monitoring and adjustments |

Common Challenges and Solutions in Measuring Chip Thickness

Typical issues faced when measuring chip thickness. Solutions and best practices for accurate measurement.Measuring chip thickness can be tricky. Many people face common challenges. These include inconsistent readings, tool wear, and improper alignment. These issues can lead to wrong measurements, which can cause problems in production. But don’t worry! Solutions exist. Here are some best practices:

- Keep tools well-maintained.

- Check alignment regularly.

- Use a calibrated milling cutter chip thickness analyzer.

Following these steps can help you achieve accurate results.

What are the typical issues in measuring chip thickness?

Typical issues include inaccurate measurements due to wear and tear on tools. Misalignment also leads to errors.

How can I ensure accurate measurements of chip thickness?

- Regular maintenance of tools.

- Proper calibration of measuring equipment.

- Regular checks for alignment.

Future Trends in Milling Cutter Technology and Chip Analysis

Innovations in milling cutter design and improvements in chip thickness analysis. The future of automation and artificial intelligence in chip measurement techniques.The world of milling cutters is buzzing with exciting changes. Engineers are designing cutters that are sharper and more efficient, which means less waste! With these innovations, chip thickness analyzers are becoming super smart. They can measure chips faster and more accurately than ever. Imagine a chip reading like a speedometer for your car!

Automation and artificial intelligence are stepping in too. Soon, machines may analyze chips all on their own, making everything quicker and easier. It’s like having a robot sidekick in the workshop! These advanced tools could cut down production time by up to 30%. Talk about a productivity boost!

| Innovation | Benefit |

|---|---|

| Smart Cutter Design | Better efficiency |

| AI Chip Measurement | Speed and accuracy |

In the future, milling will not only be faster but also fun! Is it too early to say that robots might become our new best friends in manufacturing?

Conclusion

In conclusion, a milling cutter chip thickness analyzer helps you measure the thickness of chips produced during milling. This tool improves machining accuracy and efficiency. Understanding chip thickness can lead to better tool selection and longer tool life. You can explore more about this analyzer to enhance your milling skills. Check out resources or guides if you’re interested!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Chip Thickness Analyzers:Sure! A milling cutter chip thickness analyzer helps us measure how thick the chips are that machines cut. This tool helps make sure we are cutting correctly. It can tell us if we need to change the cutter or adjust our machine. Knowing the chip thickness helps make better parts and saves time. It’s like checking the size of cookies before baking to get them just right!

Sure! Please provide the question you’d like me to answer, and I’ll help you out.

What Is The Principle Of Operation For A Milling Cutter Chip Thickness Analyzer, And How Does It Measure Chip Thickness During The Milling Process?A milling cutter chip thickness analyzer helps us see how thick the chips are when we cut metal. It uses special tools to measure the thickness as we work. When we cut, the analyzer looks at the chips and sends the measurements to a screen. This helps us know if the cutting is going well and if we need to change anything. It makes our work faster and more accurate!

How Do Different Milling Cutter Geometries Affect Chip Thickness, And Can A Chip Thickness Analyzer Help Optimize Cutter Design?Different milling cutter shapes can change how thick the chips of material are when we cut. If a cutter has sharp edges, it makes thinner chips. If the edges are dull or rounded, the chips can be thicker. A chip thickness analyzer helps us see how thick the chips are. This way, we can make better cutter designs that work nicely and cut more efficiently.

What Are The Advantages Of Using A Chip Thickness Analyzer In Milling Operations, Particularly In Terms Of Product Quality And Tool Life?Using a chip thickness analyzer helps us measure how thick the chips are during milling. This means we can make better products because we know if the cuts are just right. If we do it correctly, our tools last longer too. So, we get good quality and save money on tools. It’s a win-win for our work!

How Can Advancements In Sensor Technology Improve The Accuracy And Efficiency Of Milling Cutter Chip Thickness Analyzers?Advancements in sensor technology can make milling cutter chip thickness analyzers better. New sensors can see smaller details, helping us measure chips more accurately. They can also work faster, so we get results quickly. Better sensors can even tell us if something is wrong with the cutter. This means we can fix problems before they cause big issues.

What Types Of Data Analysis Techniques Can Be Applied To The Measurements Obtained From A Chip Thickness Analyzer To Enhance Milling Process Performance?To improve our milling process, we can use a few data analysis techniques. First, we can look for patterns in the chip thickness measurements. This helps us see how changes affect the process. We can also compare today’s measurements to past ones to find what works best. Finally, using graphs can help us spot problems quickly.