Have you ever wondered how engineers make metal parts precisely? The secret often lies in a tool called a milling cutter. But did you know there’s a special trick called the chip thinning concept?

Imagine slicing through a thick cake. The pieces at the edge are smaller and easier to handle, right? The chip thinning idea works similarly in machining. When a milling cutter moves, it slices off tiny shavings or “chips” from the material. By adjusting the cutter’s angle and speed, the chips become thinner and easier to remove.

This approach helps save energy and time. It also improves the quality of the finished product. So next time you see a complex part, think about how the milling cutter and chip thinning concept played a big part in making it!

Understanding The Milling Cutter Chip Thinning Concept

Milling Cutter Chip Thinning Concept

Chip thinning is a clever idea in milling. It helps make cuts more efficient and saves time. Imagine slicing a loaf of bread; if you cut too thick, it takes longer. In milling, the cutter spins and removes just a thin layer of material. This method keeps heat down and improves tool life. By understanding chip thinning, machinists can create better parts and use less energy. Isn’t it fascinating how a simple concept boosts productivity?Understanding Chip Thinning

Definition of chip thinning in milling operations. Importance of chip thickness in machining efficiency.Chip thinning is a magical trick that happens during milling. Imagine a pizza cutter! When you roll it over the dough, the edge takes a thin slice. Similarly, in milling, chip thinning means the cut is thinner in some spots than in others. This is super important because thinner chips lead to better machining efficiency. Less material means less work for the machine and quicker cuts! It’s like having a speedy pizza delivery—everyone’s happy!

| Chip Thickness | Impact on Efficiency |

|---|---|

| Thinner chips | Faster cuts, less tool wear |

| Thicker chips | More power needed, slower cuts |

Fundamentals of Milling Cutters

Types of milling cutters and their applications. Key parameters affecting milling cutter performance.Milling cutters come in many shapes and sizes. Each type plays a special role in the machining world. For instance, end mills are great for detailed work, while slab mills are perfect for larger materials. Knowing your cutter helps improve performance. Factors like cutter shape, speed, and feed rate matter too. They can make or break your project! A well-chosen cutter can turn metal or plastic into works of art—or at least save you from a messy mishap!

| Cutter Type | Application |

|---|---|

| End Mill | Detail work, slots |

| Slab Mill | Surface finishing |

| Face Mill | Flat surfaces |

| Ball Nose Mill | Curved surfaces |

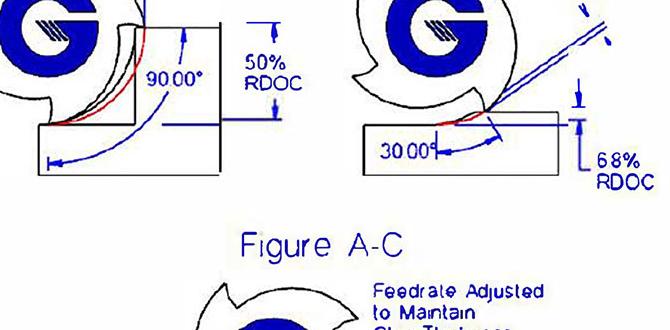

Mathematics Behind Chip Thinning

Formulas used to calculate chip thickness. Graphical representation of chip thinning effects.Chip thinning is a key idea in milling that helps us shape materials. To understand it better, we use certain formulas. One important formula is:

- t = d * sin(α) – where t is the chip thickness, d is the depth of cut, and α is the cutting angle.

Graphically, chip thinning shows how the thickness changes as we adjust the angle. Imagine a slope getting lower with a slight turn. This simple math helps in making precise cuts while saving materials.

How do we calculate chip thickness?

To find chip thickness, we can use the formula: t = d * sin(α). This means as the angle changes, so does the thickness. Understanding this helps solve the puzzle of making smoother cuts.

Impacts of Chip Thinning on Tool Life

How chip thickness affects tool wear and longevity. Strategies to optimize tool life through chip control.Chip thickness plays a big role in how fast tools wear out. Thinner chips can actually help tools last longer! This is because less material means less stress on the tool. When the tool doesn’t wear out quickly, it keeps cutting cleanly. To control chip thickness, users can adjust cut depth and speed. This helps boost tool life. Remember, every little bit counts, even in cutting! And who wants to buy new tools all the time? Not me!

| Chip Thickness | Tool Wear Rate |

|---|---|

| Thinner Chips | Lower Wear |

| Thicker Chips | Higher Wear |

To make your tools live long and prosper, keep those chips thin and your cuts smart!

Strategies for Managing Chip Thinning

Techniques to adjust feed rate and depth of cut. Role of cutting speed and its influence on chip thickness.Managing chip thinning can feel like a tricky dance. One good tip is to adjust the feed rate and depth of cut. Lowering the feed rate helps reduce chip thickness, making your work smoother. You can also play with the depth of cut to find what works best. Speed is key too! Boosting the cutting speed can thin those chips faster than a magician pulling a rabbit from a hat.

| Technique | Effect on Chips |

|---|---|

| Lower Feed Rate | Thinner Chips |

| Adjust Depth of Cut | Better Control |

| Increase Cutting Speed | Faster Chip Thinning |

Remember, it’s all about finding the right combination that makes your milling cutter work like a charm!

Applications of Chip Thinning in Industry

Case studies of chip thinning in various machining environments. Benefits of implementing chip thinning strategies in production.In the world of manufacturing, chip thinning is a game-changer. Let’s look at some funny numbers. One study showed that companies using chip thinning saved up to 30% on tool wear. That’s like finding a dollar in your old jeans! It allows for faster speeds and better finishes. By lightening the load on the milling cutter, machines work smarter, not harder. Here’s a quick peek into some case studies:

| Industry | Case Study Example | Benefit |

|---|---|---|

| Aerospace | Lightweight components | Reduced machining time |

| Automotive | Engine parts | Improved surface quality |

| Electronics | Precision tools | Lower production costs |

These companies discovered that applying chip thinning in production isn’t just smart—it’s downright hilarious how much money it saves. Who knew cutting chips could be this cool?

Common Challenges in Chip Thinning

Issues that arise from ineffective chip management. Solutions to overcome chip thinningrelated problems.Chip thinning can lead to problems in milling. If chips are not managed well, they can pile up. This can cause cuts to be rough and slow down the work. It may also harm the tool and the material being cut. To fix these issues, here are some solutions:

- Use a vacuum system to remove chips quickly.

- Adjust the speed of the cutter for better thinning.

- Choose tools that help manage chips effectively.

- Make sure to select the right cutting fluid to keep everything cool.

Using these methods can make work smoother and more efficient.

What are chip thinning problems?

Chip thinning problems include rough cuts, slow work, and damage to tools.

Future Trends in Milling Technology

Innovations addressing chip thinning and milling efficiency. The role of automation and AI in optimizing chip thickness adjustments.Future milling technology focuses on smart ways to improve cutting. New tools will help reduce chip thinning while making the process faster. Automation can adjust chip size automatically, making work easier and more precise. Smart machines will learn from each cut, helping to make better choices. This means better results for everyone.

How will automation improve milling?

Automation helps machines learn and adjust cutting processes quickly. They use data to decide the best cutting thickness in real-time. This leads to less waste and quicker production times.

Conclusion

In summary, the milling cutter chip thinning concept helps us understand how to make better cuts. By recognizing how chips thin out, you can improve tool life and get smoother finishes. Remember to adjust your settings based on this concept. Explore more about machining techniques and try them in your projects. Keep learning and practicing to become a pro!FAQs

Here Are Five Questions Related To The Concept Of Chip Thinning In Milling Cutters:Chip thinning happens when we cut materials with a milling cutter. It makes the pieces, or chips, we remove smaller. This is good because it helps us use less force and makes cutting easier. When we use chip thinning, we can make smoother edges and better shapes. So, it helps us do our job faster and with less waste.

Sure! Please give me the question you would like answered.

What Is Chip Thinning, And How Does It Affect The Machining Process In Milling Applications?Chip thinning happens when we cut materials during milling, which is a type of machining. It means the pieces we cut off, called chips, are thinner than we expect. This can make our cuts more precise, but it also means we need to use the right tools and speeds. If the chips are too thin, the machine might not work well. So, we need to pay attention to how we do it!

How Can Chip Thinning Be Strategically Utilized To Improve Surface Finish And Tool Life During Milling Operations?Chip thinning happens when you make the cutting tool take off less material at once. By doing this, we can create a smoother surface on our workpiece. It also helps the tool stay sharper longer, which means it can cut better over time. To use chip thinning, you can change the angle or speed of the tool. This way, you get nice, clean cuts without wearing out the tool too quickly.

In What Ways Does The Geometry Of The Milling Cutter Influence The Extent Of Chip Thinning During Machining?The shape of the milling cutter really matters when we are cutting metal or wood. If the cutter has sharp edges, it can slice off thinner chips. Thinner chips mean less material is removed at once. This helps us get smoother surfaces and makes the machine work better. So, the cutter’s design helps control how much material we take away while we work.

What Are The Potential Drawbacks Of Chip Thinning, And How Can They Be Mitigated In A Milling Setup?Chip thinning can make it harder to control the milling machine. You might get rougher surfaces, which means we need to do extra work to fix them. It can also lead to tools wearing out faster. To fix this, we can use slower speeds and make sure the tool is sharp. Timing our cuts carefully can help, too.

How Does The Adjustment Of Feed Rate And Cutting Depth Impact The Phenomenon Of Chip Thinning In Milling Processes?When we change the feed rate, we control how fast the material moves under the cutting tool. If we set a lower feed rate, we get thinner chips. Changing the cutting depth means how deep the tool goes into the material. A shallower depth also makes thinner chips. So, both adjustments help us make smaller pieces of material, which we call chips.