Have you ever wondered how tools can cut through tough materials? It’s all about the right coating on a milling cutter! Many people don’t realize how important milling cutter coating is, especially when working with abrasive materials.

Imagine trying to cut through rock using a dull knife. Frustrating, right? Now, picture a sharp knife made to handle that tough job. That’s what the right milling cutter coating does for your tools. It protects them from wear and helps them last longer.

Here’s a fun fact: Coatings can be made of different materials, like titanium. These special coatings make milling cutters more effective and can save time and money. With the right choice, you can improve your machining process. Why settle for ordinary when you can upgrade your tools?

In this article, we’ll explore the fascinating world of milling cutter coating for abrasive materials. Let’s dive into how these coatings work and why they are a game-changer for anyone working with tough materials.

Milling Cutter Coating For Abrasive Materials: Enhance Performance Introduction In The World Of Machining And Manufacturing, The Choice Of Tools Can Significantly Impact Productivity And Efficiency. One Such Tool That Plays A Crucial Role Is The Milling Cutter, Especially When Dealing With Abrasive Materials. The Right Coating On A Milling Cutter Can Not Only Extend Its Lifespan But Also Improve Its Cutting Performance. In This Article, We Will Explore Various Milling Cutter Coatings Designed Specifically For Abrasive Materials, Along With Their Benefits, Types, And Applications. Importance Of Coating On Milling Cutters Milling Cutters Are Subjected To High Levels Of Friction And Heat During Operation. Coatings Can Help Reduce Wear And Tear, Leading To Longer Tool Life. Additionally, The Right Coating Can Enhance The Cutting Edge’S Hardness And Improve Chip Removal, Which Is Crucial When Working With Abrasive Materials. Common Coatings For Milling Cutters 1. **Tin (Titanium Nitride)** – **Description**: A Hard, Wear-Resistant Coating That Improves Tool Life. – **Usage**: Ideal For General Purpose Milling Applications. 2. **Tialn (Titanium Aluminum Nitride)** – **Description**: Offers Higher Thermal Stability And Oxidation Resistance. – **Usage**: Suitable For High-Speed Machining Of Abrasive Materials. 3. **Alcrn (Aluminum Chromium Nitride)** – **Description**: Provides Excellent Wear Resistance And Thermal Barrier Properties. – **Usage**: Effective For Extreme Cutting Conditions. 4. **Diamond Coating** – **Description**: Extremely Hard And Resistant To Wear. – **Usage**: Preferred For Very Hard And Abrasive Materials, Such As Composites. Benefits Of Coatings For Abrasive Materials – **Increased Tool Life**: Coatings Help Reduce Wear, Allowing For Longer Intervals Between Tool Changes. – **Improved Surface Finish**: A Smoothly Coated Cutter Produces Finer Finishes On Workpieces. – **Enhanced Performance**: Coated Tools Can Operate At Higher Speeds And Feeds, Contributing To Overall Productivity. Conclusion The Right Milling Cutter Coating For Abrasive Materials Is Crucial In Today’S Manufacturing Processes. Selecting An Appropriate Coating Based On The Specific Application Can Significantly Enhance Cutting Efficiency, Reduce Downtime, And Optimize Production Costs. As Technologies Continue To Advance, The Development Of New Coatings Is Likely To Provide Even Better Solutions For Machining Challenges. Choosing The Right Tools Equipped With Specialized Coatings Is An Investment Toward Achieving Peak Performance In Machining Operations.

Milling Cutter Coating for Abrasive Materials

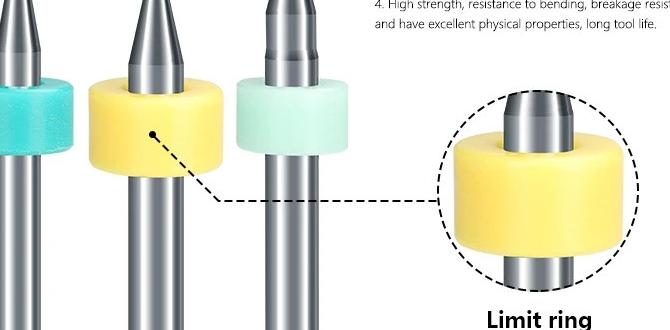

Milling cutter coatings enhance cutting tools used on hard materials. They increase durability and improve performance. For instance, coatings like TiN or TiAlN help cutters last longer when working with tough substances. Imagine trying to cut through solid rock; you’d need a strong tool! Coatings reduce friction and heat, allowing smoother cuts. Did you know that a good coating can double the cutter’s life? Choosing the right coating means better results for your projects!Types of Coatings for Abrasive Material Milling Cutters

Description of various coating types (TiN, TiAlN, etc.). Advantages and disadvantages of each coating type.Coatings can turn a regular milling cutter into a super tool! Let’s look at a few types.

| Coating Type | Advantages | Disadvantages |

|---|---|---|

| TiN (Titanium Nitride) | Great hardness & long tool life! | Sensitive to heat. |

| TiAlN (Titanium Aluminum Nitride) | Good for high temperatures & excellent wear resistance! | Can be more expensive. |

| CrN (Chromium Nitride) | Helpful with heat & good for non-ferrous materials! | Less durable than TiN. |

Each coating has its own charms. TiN sparkles like a diamond and lasts long. TiAlN is the party animal for hot jobs! But remember, choose wisely or your cutter might end up crying like a toddler in a candy store.

Selection Criteria for Coating Abrasive Materials

Factors influencing coating selection (material hardness, cutting speed, etc.). Influence of workpiece material on coating choice.Choosing the right coating for abrasive materials is no joke! It depends on several key factors. First, consider the material’s hardness. Harder materials need tougher coatings, like a superhero in armor! Next, think about cutting speed. Faster speeds can wear down coatings quicker, so choose wisely. Lastly, the type of material you’re working with can sway your choice. Steel? Go for a durable coating. Plastic? A softer touch may work. It’s all about matching the coating to the job at hand!

| Factor | Consideration | Recommendation |

|---|---|---|

| Material Hardness | Harder materials require stronger coatings. | Use tough coatings for high hardness. |

| Cutting Speed | Higher speeds wear coatings faster. | Choose durable coatings for rapid cutting. |

| Workpiece Material | Different materials need different coatings. | Match coating to material type. |

Benefits of Using Coated Milling Cutters

Increased tool life and performance. Improved surface finish and precision in machining.Using coated milling cutters has many perks. First, they last longer and work better. This means less time spent on changing tools. Second, they create smoother and more precise surfaces during machining. Your projects look better and are more accurate. Coated tools can handle tough materials easily. That helps improve the overall quality. Isn’t it great to have tools that help us work smarter?

What are the main benefits of coated milling cutters?

Coated milling cutters increase tool life and enhance performance while improving the surface finish and precision in machining.

Key Advantages:

- Longer lifespan of tools

- Better cutting efficiency

- Smoother surface finish

- Higher accuracy in machining

Optimal Cutting Parameters for Coated Milling Cutters

Recommended speeds and feeds for various coatings. Impact of cutting conditions on coating durability.Choosing the right speed and feed for coated milling cutters is crucial. For example, high-speed steel coatings work best at moderate speeds. This can help improve durability and reduce wear. Similarly, carbide coatings typically shine with faster feeds. Less friction leads to better coating life!

The cutting conditions can greatly influence how well the coating lasts. Too much pressure can dull the edges faster. Always monitor the cutting environment to protect the coating.

What speeds and feeds work best with different coatings?

High-speed steel coatings do well at lower speeds, while carbide coatings prefer higher speeds. Ideal feed rates help maintain cutting efficiency without damaging the tool.

Recommended Cutting Parameters:

- High-speed steel: 100-200 RPM

- Carbide: 300-600 RPM

Maintenance and Care for Coated Milling Cutters

Best practices for cleaning and storing coated tools. Importance of regular inspections and recoating when necessary.Caring for coated milling cutters is like giving your tools a spa day. First, always clean them after use. You can wash them gently with soap and water. Avoid harsh chemicals; they can ruin the coating. Store them in a dry place, away from moisture. Regular checks are important too. Look for wear and tear often. If your cutters look tired, recoating might be needed. Remember, a happy cutter means a happy job!

| Best Practices | Do’s | Don’ts |

|---|---|---|

| Cleaning | Use soap and water | Avoid harsh chemicals |

| Storing | Keep in a dry place | Don’t store in humidity |

| Inspection | Check for wear regularly | Ignore signs of damage |

Case Studies: Performance of Coated vs. Uncoated Milling Cutters

Comparative analysis of productivity and precision. Examples from different industries (aerospace, automotive, etc.).Coated milling cutters work better than uncoated ones. They make cutting faster and more precise. For example:

- Aerospace: Coated cutters help shape tough materials like titanium.

- Automotive: They improve engine part manufacturing, increasing accuracy.

- Construction: Coated tools cut through cement faster and reduce wear.

This coating allows tools to last longer and save money. Tests show that productivity increases by up to 30% with coated tools. The right choice makes a big difference in many fields.

How do coated cutting tools compare in productivity?

Coated tools increase productivity by reducing friction, leading to faster cutting speeds and longer tool life.

Future Trends in Milling Cutter Coatings

Innovations in coating technology and materials. Predictions for the future of milling cutter coatings in the market.New advancements in milling cutter coatings are popping up like popcorn at a movie! Researchers are busy finding stronger, lighter materials while making coatings more durable. By using innovative technologies, companies aim to improve performance with less wear and tear. Predictions say these coatings will become tougher and more affordable, making them a hit in the market. Everyone loves a shiny, new toy, and everyone will want these cutters!

| Innovation | Description |

|---|---|

| Nanotechnology | Using tiny particles to enhance strength and reduce friction. |

| Diamond Coatings | Adding diamond layers for super hardness. |

| Eco-Friendly Options | Creating coatings that are safe for the environment. |

Conclusion

Milling cutter coatings are essential for working with abrasive materials. They help reduce wear, improve tool life, and enhance cutting performance. Choosing the right coating is crucial for achieving better results. We encourage you to learn more about different coatings and how they can benefit your projects. Explore more resources to make informed choices for your tools!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Coatings For Abrasive Materials:Coatings on milling cutters help them cut materials better and last longer. They protect the cutter from wear and heat. This means you can use them more without breaking or changing them. It’s like putting a strong armor on a warrior, making them tougher in a battle. So, when we use coated cutters, we get better work done!

Sure! Please provide the question you’d like me to answer.

What Are The Benefits Of Using Specialized Coatings On Milling Cutters When Machining Abrasive Materials?Using special coatings on milling cutters helps them last longer when they cut tough materials. These coatings make the cutters stronger and less likely to wear out. They also help the cutters slide better, so they work more smoothly. This means you can finish your work faster and with better results. Overall, coatings help you save time and money!

How Do Different Coatings, Such As Tin, Tialn, Or Diamond, Compare In Terms Of Wear Resistance And Longevity When Cutting Abrasive Materials?Different coatings help tools last longer when cutting tough materials. Titanium nitride (TiN) is good but not the best. Titanium aluminum nitride (TiAlN) is better and lasts longer. Diamond coatings are the strongest and last the longest. So, if you want a tool to cut well and last, diamond is the best choice.

What Factors Should Be Considered When Selecting A Coating For Milling Cutters Intended For Use On Specific Abrasive Materials?When choosing a coating for milling cutters, you should think about how hard the material is. Some coatings work better on tough materials than others. You should also consider how much heat the cutter will face. A good coating can help the cutter last longer. Finally, make sure the coating can resist wear from the abrasives.

How Does The Thickness Of The Coating On A Milling Cutter Impact Its Performance And Durability When Working With Abrasive Materials?The thickness of the coating on a milling cutter affects how well it cuts and lasts. Thicker coatings can make the cutter stronger and help it resist damage from rough materials. This means it won’t wear out as quickly. So, using a thicker coating can help you work better and longer with tough stuff!

What Advancements In Coating Technology Are Being Developed To Enhance The Performance Of Milling Cutters Used In The Machining Of Highly Abrasive Materials?Scientists are creating new types of coatings for milling cutters. These coatings help tools last longer when cutting tough materials. Some new coatings can resist heat and wear better. This means we can use our tools for a longer time without breaking them. So, our work gets easier and more efficient!