Imagine a robot arm working in a factory. It moves quickly and precisely. Now, picture it using a milling cutter to shape metal parts. Sounds cool, right? But here’s the catch: not all milling cutters fit all robotic arms. This makes choosing the right cutter very important.

Why does it matter? If the wrong cutter is used, it can lead to mistakes. These mistakes can slow down production. Nobody wants that! A great match between the milling cutter and robotic arm keeps everything running smoothly.

Have you ever wondered how these tools work together? The compatibility between milling cutters and robotic arms can change how factories operate. This article will explore why this match is so crucial. You’ll learn how choosing the right milling cutter makes robotic arms even better at their jobs.

Join us as we discover the world of milling cutter compatibility. We promise it’s an exciting journey!

Milling Cutter Compatibility With Robotic Arms Explained

Choosing the right milling cutter for robotic arms is essential for smooth operations. Observing how different cutters function can lead to better automation outcomes. Did you know that specific milling cutters can increase precision in tasks like cutting metal? Matching the right cutter with the right robot improves efficiency and quality. Understanding compatibility can save time and cost while boosting productivity. The future of smart manufacturing relies heavily on this harmony between tools and machines.

Understanding Robotic Arms

Definition and types of robotic arms in manufacturing. Key features that determine compatibility with tools.

Have you ever seen a robot arm move? It’s like watching a magician but without the rabbits! Robotic arms are machines that assist in manufacturing. They come in different types, like Cartesian, SCARA, and articulated arms. Each type has unique abilities, making them special for certain tasks.

Key features that decide how well tools fit with these arms include weight capacity, precision, and range of motion. These traits ensure the right tools, like milling cutters, do their job effectively without knocking over anything, including the coffee cup!

| Type of Robotic Arm | Best Use | Key Features |

|---|---|---|

| Cartesian | 3D printing | High precision |

| SCARA | Assembly tasks | Simple motion |

| Articulated | Welding | Great flexibility |

Factors Affecting Compatibility

Size and shape of the milling cutter. The range of motion and precision of robotic arms.

Several factors affect how well a milling cutter fits with robotic arms. First, the size and shape of the milling cutter must match the robotic arm’s design. If it’s too big or odd-shaped, it won’t work well. Second, the robotic arm’s range of motion and precision matter. An arm that moves easily can handle more tasks with accuracy. Both these factors ensure smooth operation and great results.

What is important for milling cutter and robot arm compatibility?

Size, shape, range of motion, and precision are crucial for compatibility. They work together for effective performance.

Industry Applications

Common industries utilizing robotic arms and milling cutters. Case studies demonstrating effective compatibility in realworld scenarios.

Robotic arms and milling cutters work wonders in many industries. They are like peanut butter and jelly, perfect partners! Common fields include automotive, aerospace, and electronics. In these sectors, the arms can handle complex shapes and tough materials with ease.

Take the automotive industry, for example. Companies use robotic arms and milling cutters to create precise engine parts. This combo speeds up production and improves quality. One case study showed a 30% increase in efficiency! Crazy, right?

| Industry | Application | Result |

|---|---|---|

| Automotive | Precision Engine Parts | 30% Increased Efficiency |

| Aerospace | Aircraft Components | Improved Safety and Reliability |

| Electronics | Circuit Board Milling | Higher Accuracy |

With amazing results like these, it’s easy to see why robotic arms and milling cutters are the dream team in modern manufacturing!

Choosing the Right Milling Cutter for Robotic Applications

Guidance on selecting milling cutters based on robotic arm specifications. Recommendations for brands known for compatibility with robotic arms.

Finding the best milling cutter for a robotic arm is key to smooth operations. First, check the robot’s specs, like weight capacity and speed. This helps match the cutter’s size and shape. Good brands to consider include General Tools, Makita, and Bosch. They are known for making cutters that work well with robotic arms. So, pick your tool wisely or risk your robot becoming a rolling paperweight!

| Brand | Compatibility |

|---|---|

| General Tools | High |

| Makita | Medium |

| Bosch | High |

Challenges in Milling Cutter and Robotic Arm Compatibility

Common issues faced in compatibility and performance. Solutions and best practices to overcome these challenges.

Mixing milling cutters with robotic arms can be tricky. Common bumps include mismatched sizes and different speeds, which can make quality control feel like a bad joke! Imagine two dance partners stepping on each other’s toes. But don’t worry! Solutions exist. Using the right adapters and fine-tuning speeds can save the day. Always keep the setup clean and well-maintained. A little patience and planning go a long way—like a robot that finally learned to boogie!

| Issue | Solution |

|---|---|

| Mismatched Sizes | Use appropriate adapters |

| Speed Differences | Fine-tune motor speeds |

| Quality Control | Maintain clean setups |

Future Trends in Robotic Arm and Milling Cutter Integration

Innovations in milling cutter design for enhanced compatibility. Predictions for the evolution of robotic arms and tooling industries.

Exciting changes are on the horizon for the connection between robotic arms and milling cutters. New designs for milling cutters aim to improve their compatibility. Innovations may include flexible materials and smart sensors. These features help cutters adjust perfectly to robotic movements.

Experts predict that robotic arms will become even more advanced. They may use artificial intelligence to learn and adapt faster. This will make them more efficient and accurate in their tasks, changing the tooling industry forever.

What are some trends in this field?

- Use of lightweight materials will improve movement.

- Smart technology will increase precision.

- Collaboration between engineers will boost innovation.

Conclusion

In conclusion, understanding milling cutter compatibility with robotic arms is crucial. Use the right cutter for smooth operations. Remember, different materials need different cutters. We can enhance efficiency by learning more about these tools. You can explore tutorials or guides online for deeper knowledge. Let’s keep improving our skills and make the most of robotic cutting technology together!

FAQs

What Criteria Should Be Considered When Selecting Milling Cutters For Use With Robotic Arms?

When choosing milling cutters for robots, we should think about several things. First, consider the material you will cut, like metal or wood. Next, think about the cutter size; it should fit the robot’s arm. Also, check how strong and durable the cutter is to last a long time. Lastly, make sure the cutter matches the speed the robot can go.

How Do The Speed And Torque Specifications Of Robotic Arms Affect The Performance Of Milling Cutters?

The speed of a robotic arm tells us how fast it can move. When it’s fast, it can cut through materials quickly. Torque helps the arm apply force, which is important for pushing the milling cutter into the material. If a robotic arm has good speed and torque, it can make smoother cuts and finish jobs faster. So, the better these specs are, the better the robotic arm works with milling cutters.

What Are The Advantages Of Integrating Adaptive Milling Cutters With Robotic Machining Systems?

Using adaptive milling cutters with robotic machines is great because they adjust to different shapes. This helps make better and faster cuts. Robots can work for a long time without getting tired, which saves time. You also get less waste since the cutters use the right amount of material. Overall, this teamwork makes finishing projects easier and more fun!

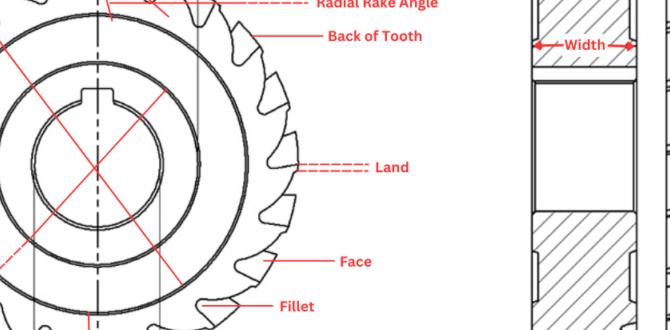

How Can The Design Of A Milling Cutter Influence The Precision And Efficiency Of Robotic Milling Operations?

The design of a milling cutter affects how well a robot can cut materials. A sharp cutter makes clean cuts and keeps shapes accurate. If the cutter is sturdy, it won’t break or wear down quickly, which saves time. Good design also helps the robot work faster, so we finish tasks more quickly.

What Safety Measures Should Be Implemented When Using Milling Cutters In Conjunction With Robotic Arms To Minimize Risks?

When using milling cutters with robotic arms, we need to be very careful. First, always wear safety glasses and gloves. We should keep our hands clear of the moving parts. It’s important to have a safety switch that stops the robot if there’s a problem. Also, make sure everyone working nearby understands the danger zone.