Have you ever wondered how machines create complex shapes from strong materials? One vital tool in this process is the milling cutter. It plays an essential role in working with composite materials. These materials are becoming popular in many industries, including aerospace and automotive.

Milling cutters are designed with sharp edges. These edges cut through tough materials with precision. But what exactly makes a milling cutter special when it comes to composite material cutting edges? The answer lies in their design and the materials used to make them.

Did you know that using the right milling cutter can increase efficiency and quality? It’s true! With the right tool, manufacturers can produce items faster and better than ever before. Imagine building a new airplane with parts that are lighter and stronger. This is the magic of milling cutters.

In this article, we will explore the fascinating world of milling cutters and their cutting edges. We’ll look at how they work with composite materials and why they are so important. Ready to dive in?

Milling Cutter Composite Material Cutting Edge Explained

Milling Cutter Composite Material Cutting Edge

Milling cutter composite material cutting edges are essential in modern machining. These tools efficiently cut through tough materials, offering precision and durability. But what makes them special? They combine various materials, enhancing strength and reducing wear. Imagine crafting parts with less effort and greater accuracy! This composite design also helps in maintaining sharpness longer, reducing the frequency of replacements. By understanding these cutting edges, manufacturers can boost productivity while saving costs. Isn’t that fascinating?Understanding Composite Materials

Definition and types of composite materials. Importance of composite materials in various industries.Composite materials are made by mixing two or more different materials to create a new one with better properties. They come in types like fiber-reinforced polymers, metal matrix composites, and ceramic matrix composites. These materials are super important in industries like aerospace, automotive, and construction, where strength and lightness matter. Think of it like a superhero team, where each material has its own special power to save the day!

| Type of Composite | Properties | Industry Use |

|---|---|---|

| Fiber-Reinforced Polymer | High Strength | Aerospace |

| Metal Matrix Composite | Lightweight | Automotive |

| Ceramic Matrix Composite | Heat Resistant | Construction |

Types of Milling Cutters for Composite Material

Solid carbide milling cutters: Benefits and applications. Diamondcoated milling cutters: Features and advantages.Milling cutters play a big role in cutting composite materials. One type is solid carbide milling cutters. They are strong and last a long time. This makes them perfect for tough jobs. Benefits include high precision and heat resistance. They work well with various composites.

Another type is diamond-coated milling cutters. These have a special coating that helps them cut smoothly. Features include reduced friction and increased durability, making them suitable for demanding tasks.

- Solid carbide cutters offer excellent strength.

- Diamond-coated cutters provide a very smooth finish.

Why choose solid carbide or diamond-coated cutters?

Using solid carbide or diamond-coated cutters can lead to better results. They improve efficiency and longevity, reducing overall costs.

Factors Influencing Milling Cutter Selection for Composites

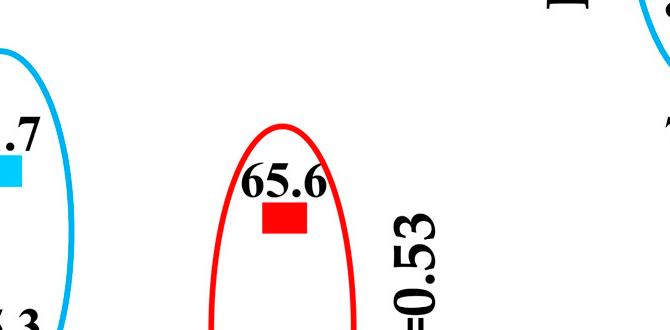

Material properties of composites: Hardness, abrasiveness, and thermal sensitivity. Cutter geometry: Tooth design, rake angle, and number of flutes.Choosing the right milling cutter for composites is like picking the perfect ice cream flavor—there are many factors to consider! First, think about the composites’ material properties. Their hardness and abrasiveness might make things tricky, while thermal sensitivity can spell disaster if overheated. Next, don’t overlook the cutter geometry. Tooth design, rake angle, and the number of flutes affect how smoothly the cutter slices through materials. Every little detail counts!

| Factor | Details |

|---|---|

| Material Hardness | Affects cutting speed. |

| Abrasiveness | Can wear out tools faster. |

| Thermal Sensitivity | Risk of melting during cuts. |

| Tooth Design | Influences chip removal. |

| Rake Angle | Affects cutting efficiency. |

| Number of Flutes | Determines material removal rates. |

So, consider these elements carefully to ensure cutting success. After all, nobody wants a melt-down on their hands—unless it’s chocolate sauce!

Best Practices for Milling Composite Materials

Optimal cutting parameters: Speed, feed rate, and depth of cut. Cooling and lubrication techniques: Importance in maintaining cutter performance.To cut composite materials successfully, select the right cutting speed, feed rate, and depth. Use faster speeds with lower depth for better results. This balances cutter wear and material quality. Remember lubrication. It keeps the milling cutter cool and running well, avoiding damage to the cutting edge. Cutting can be tough, but good techniques help maintain performance.

What are optimal cutting parameters for composite materials?

Good cutting speed, appropriate feed rate, and correct depth of cut are key. They help in slicing through materials smoothly and effectively.

Key points to remember:

- Speed: Faster speeds work well.

- Feed Rate: Adjust according to material type.

- Depth of Cut: Make it shallow to reduce wear.

So, use these best practices to get the most out of your milling cutter for composite materials.

Common Challenges in Composite Material Milling

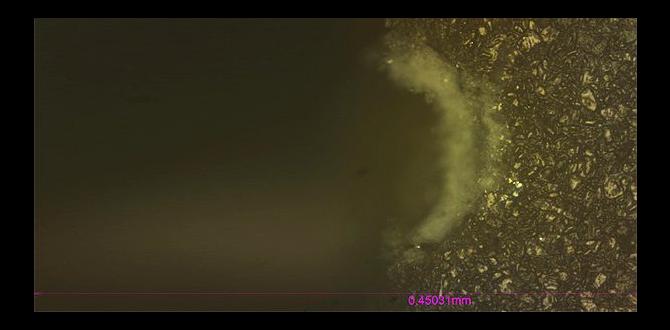

Issues with delamination and surface quality. Tool wear characteristics and how to mitigate them.Milling composite materials can be tricky. One big problem is delamination. This happens when layers of the material separate. It can lower the surface quality. Another issue is tool wear. As tools cut, they can become dull. Dull tools affect how well the material cuts. To reduce wear, use proper speeds and feeds. Regular tool checks help too.

- Keep cutting speeds low.

- Select the right tool material.

- Perform regular maintenance.

What causes delamination in composite materials?

Delamination in composite materials often happens due to high cutting forces and improper tool settings. Cooling the tool also helps keep it sharp and minimizes delamination risk.

Future Trends in Milling Cutter Technology for Composites

Advances in materials for milling cutters. Integration of smart technology and automation in cutter design.The world of milling cutters is buzzing with exciting changes! Innovations in materials make cutters stronger and longer lasting. New composites can handle tough jobs without breaking a sweat. Meanwhile, smart technology is stepping in. It helps design cutters that adjust on the fly, making them better at their tasks. Picture a cutter that knows just when to sharpen itself—now that’s smart!

| Advancements | Description |

|---|---|

| New Materials | Stronger composites enhance durability and performance. |

| Smart Technology | Automatic adjustments for optimal cutting. |

As technology moves forward, we can expect even more surprises from milling cutters. They’re shaping up to be smarter and tougher than ever!

Case Studies: Successful Applications of Milling Cutters in Composite Manufacturing

Aerospace industry: Innovations and efficiency improvements. Automotive sector: Cuttingedge approaches and outcomes.In the aerospace industry, milling cutters have brought exciting innovations. They make cutting composite materials easier and faster, boosting efficiency. Imagine a jet being built quicker than your lunch can get cold! The automotive sector is also racing ahead with these tools. They apply creative machining methods and see fantastic results. Less time spent cutting means more time driving your shiny new car!

| Industry | Benefits of Milling Cutters |

|---|---|

| Aerospace | Faster production, improved efficiency |

| Automotive | Innovative techniques, better outcomes |

Conclusion

In conclusion, milling cutter composite materials provide strong and durable cutting edges for better performance. They enhance precision and efficiency in machining. You can explore more about their benefits and applications to improve your skills. Remember, using the right tools makes all the difference in any project. So, keep learning and experimenting with different materials!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Composite Material Cutting Edges:Sure! Here are five questions about milling cutters. What is a milling cutter? It’s a tool that helps cut shapes from hard materials. Why are composite materials used? They are strong, light, and can be shaped easily. How do we make cutting edges? We use special materials and shape them very precisely. What do we need to cut with milling cutters? We need a machine, the right cutter, and the material you want to cut. Why is it fun to learn about these tools? We can see how they help make cool things!

Sure! Please provide the question you want me to answer.

What Materials Are Commonly Used For The Cutting Edges Of Milling Cutters Designed For Machining Composite Materials?Milling cutters for machining composite materials often use special materials. We commonly see carbide and diamond on the cutting edges. Carbide is very hard and lasts a long time. Diamond is even harder and helps cut smoothly. These materials help make sure the cutters work well and don’t wear out quickly.

How Do The Properties Of Composite Materials Affect The Wear And Durability Of Milling Cutter Cutting Edges?Composite materials are made by mixing different things together. This helps milling cutters last longer because they can handle heat and pressure better. They stay sharp for more time, which means we can cut more without changing them. Stronger and tougher materials mean less wear, so your cutter can work harder and longer!

What Are The Advantages Of Using Carbide Or Diamond-Coated Cutting Edges In Milling Composites Compared To Traditional Materials?Using carbide or diamond-coated cutting edges for milling composites has many benefits. They last longer than regular materials, so you don’t have to change them often. They also cut through materials more easily, making your work faster. These edges create smoother surfaces, which can make your projects look better. Overall, they help you work more efficiently and save time!

How Do Cutting Speed, Feed Rate, And Cooling Methods Influence The Performance Of Milling Cutters When Processing Composite Materials?Cutting speed is how fast the cutter spins. If it spins too fast, it can get too hot and break. The feed rate is how quickly we move the cutter across the material. If we go too fast, the cutter might not cut well. Cooling methods, like water or air, help keep everything cool, so the cutter lasts longer. All three factors help us make better cuts in composite materials.

What Advancements In Milling Cutter Design Are Being Researched To Improve The Efficiency And Effectiveness Of Cutting Edges For Composite Material Applications?Researchers are working on new milling cutters to make cutting easier for composite materials. They are studying shapes that help cut better and materials that last longer. Some cutters might use special coatings to keep them sharp. This way, we can cut quicker and with less waste. It’s all about making the job faster and better!