Milling is a common process in factories. It helps shape materials like metal and wood. Have you ever wondered how long a tool lasts while doing this job? One important factor is the milling cutter’s corner wear resistance. This means how well the cutting edge can handle wear and tear during use.

Imagine trying to cut a tough piece of wood with a dull knife. It doesn’t work very well, does it? Now think about a milling cutter that wears down quickly. It can slow down production and lead to costly mistakes. But with proper evaluation of corner wear resistance, we can find the tools that last longer and work better.

Did you know that some milling cutters can last several times longer than others? Understanding the reasons behind this can make a big difference. In this article, we will explore ways to evaluate milling cutter corner wear resistance. We’ll uncover tips and tricks that can help improve tool longevity. By the end, you’ll be more curious about the tools you use every day!

Milling Cutter Corner Wear Resistance Evaluation Techniques

Milling cutters face wear over time, affecting their performance. Evaluating corner wear resistance helps in selecting durable tools. Did you know that even small changes in design can significantly boost resistance? Testing different materials and coatings reveals the best options for longevity. Understanding wear patterns can save manufacturers time and money. Ensuring cutter efficiency leads to smoother operations and reduced costs. A well-chosen milling cutter can transform production quality and durability.

Understanding Corner Wear in Milling Cutters

Definition of corner wear and its significance in machining.. Factors contributing to corner wear during milling operations..

Corner wear happens when the edges of a milling cutter get worn down. This is very important in machining. It can affect the quality of the final product and how long the cutter lasts. Knowing why corner wear occurs helps us reduce it. Here are some factors that contribute to corner wear during milling operations:

- Cutting speed: Faster speeds can increase wear.

- Material type: Harder materials cause more wear.

- Cooling: Lack of cooling can cause heat buildup.

- Tool geometry: The shape of the cutter affects wear rates.

Understanding corner wear can lead to better machining practices.

What is corner wear in milling cutters?

Corner wear is the damage that happens at the cutting edges of milling tools over time.

Methods for Evaluating Wear Resistance

Description of standard testing methods for wear resistance.. Equipment and procedures used in evaluations..

To evaluate wear resistance, standard testing methods are essential. Common tests include the pin-on-disk test and the rockwell hardness test. Each method checks how materials wear over time in different conditions.

Key equipment and procedures are vital:

- Pin-on-disk tester: Measures friction and wear on materials.

- Rockwell hardness machine: Tests material hardness.

- Data analysis software: Interprets test results for better understanding.

These tools help scientists find out which materials will last longer in real-world use.

What are standard testing methods for wear resistance?

The standard tests, like the pin-on-disk and Rockwell hardness tests, measure how well materials can resist wear. This helps engineers choose the best materials for tools.

Material Selection for Milling Cutters

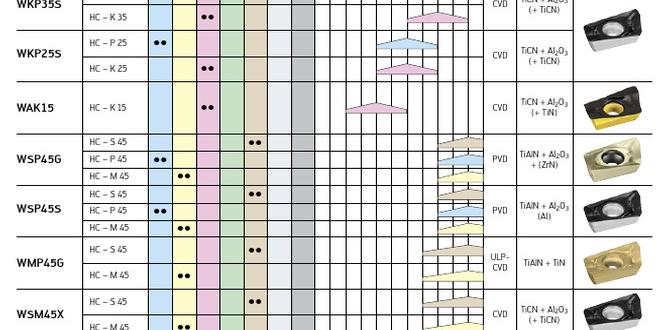

Analysis of materials commonly used for milling cutters.. Impact of material properties on wear resistance and performance..

Selecting the right material for a milling cutter is key to achieving the best results. Common materials include carbide, high-speed steel, and cobalt. Each has unique properties that affect how well they resist wear. For example, carbide is tough and holds its edge longer, while high-speed steel is easier to sharpen but wears out faster. Choosing wisely can lead to better performance, just like picking the right ice cream flavor can make dessert more enjoyable. Quality materials save time and money!

| Material | Wear Resistance | Performance |

|---|---|---|

| Carbide | High | Excellent cutting edge retention |

| High-Speed Steel | Moderate | Good for general use |

| Cobalt | High | Strong and tough |

Influence of Cutting Conditions

Examination of how speed, feed rate, and depth of cut affect corner wear.. Best practices for optimizing cutting conditions to reduce wear..

Cutting conditions play a big role in how quickly the corners of milling cutters wear down. Three key factors are speed, feed rate, and depth of cut. If you speed up too much, wear can increase. On the other hand, a slower feed rate often helps reduce wear. Finding the right mix is important. Here are some best practices:

- Keep medium speed for smoother cuts.

- Adjust feed rate for less wear.

- Limit depth to maintain cutter life.

Taking time to optimize these conditions can help your tools last longer and work better.

How do cutting conditions affect milling cutter wear?

Cutting conditions greatly affect cutter wear by controlling how much heat and pressure the tool experiences. Properly balancing these factors can ensure longer tool life and better performance.

Wear Mechanisms in Milling Cutters

Explanation of different wear mechanisms affecting corner wear.. Case studies or examples illustrating wear mechanisms in action..

Various wear mechanisms affect milling cutters, especially at their corners. Understanding these can help us improve their life. Some key mechanisms include:

- Abrasive wear: Small particles scratch the cutter surface.

- Adhesive wear: Metal binds to the surface during cutting.

- Fatigue wear: Repeated stress weakens the cutter material.

In practical cases, studies show that abrasive wear can reduce cutter life by up to 30%. Observations reveal that adhesive wear becomes prominent in high-speed operations. Fatigue wear often appears when cutters run for long periods. Choosing the right materials and speeds can help combat these issues.

What are common wear mechanisms in milling cutters?

Common wear mechanisms include abrasive wear, adhesive wear, and fatigue wear. Each mechanism plays a significant role in how well a milling cutter lasts. Understanding these helps in making better choices for cutter material.

Best Practices for Maintenance and Inspection

Recommended maintenance techniques for prolonging cutter life.. Inspection methods to monitor wear and ensure optimal performance..

Keeping your milling cutters in top shape is key to their performance. Regular cleaning is a must—think of it like a spa day for your tools. Remove any chips and debris after each use. It’s an easy way to keep them healthy.

Also, use the right coolant! This helps cool the cutters and reduces wear. Regularly check for signs of wear, like chips or dull edges. Early detection can save money. And remember, dull cutters are like tired puppies; they won’t perform!

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Clean cutters | After each use | Prevents blockage |

| Inspect for wear | Weekly | Prolongs life |

| Use proper coolant | Always | Reduces heat |

Following these practices will help keep your cutters sharp and ready to work! Plus, who doesn’t enjoy a little preventive maintenance humor? It cuts down on future headaches!

Conclusion

In conclusion, evaluating milling cutter corner wear resistance is crucial for better machining results. You learn that different materials can increase durability. Regular checks can help you catch wear early. By understanding how to evaluate wear, we can improve tool life and efficiency. For more tips on this topic, consider reading further or asking an expert for advice!

FAQs

Here Are Five Questions Related To The Evaluation Of Milling Cutter Corner Wear Resistance:

Sure! Here’s a simple answer to one of the questions about milling cutter corner wear resistance: Milling cutters are tools we use to cut materials. We check how well they last after cutting. If they wear out quickly, we can try new types of materials or shapes for better cutting. It’s important to find a cutter that stays strong so we can do our work well. We should always look for ways to make our tools last longer!

Sure! Please provide the question you’d like me to answer.

What Are The Primary Factors Affecting The Wear Resistance Of Milling Cutter Corners During Machining Operations?

The wear resistance of milling cutter corners depends on a few main things. First, the material of the cutter matters; hard materials last longer. Second, the way we use the cutter, like the speed and pressure, affects how much it wears out. Third, the type of things we are cutting, like metal or wood, can change how quickly it wears down. Finally, keeping the cutter sharp helps it last longer, too.

How Do Different Cutting Materials And Coatings Influence The Corner Wear Resistance Of Milling Cutters?

Different cutting materials, like steel or carbide, affect how long a milling cutter lasts. Harder materials cut better and wear less at the corners. Coatings, like ceramic or titanium, help protect the cutter from heat and damage. This means the cutter can stay sharp longer and make cleaner cuts. So, using the right materials and coatings helps the cutter work better and last longer!

What Experimental Methods Can Be Employed To Quantitatively Assess The Corner Wear Of Milling Cutters Under Various Machining Conditions?

We can use a few methods to measure corner wear on milling cutters. First, we could take photos of the cutter’s corners before and after using them. Then, we can compare the two pictures to see how much wear happened. We could also use a special tool to measure the size of the worn corners accurately. Lastly, testing cutters under different speeds and materials helps us understand how wear changes in each condition.

How Does The Geometry Of The Milling Cutter, Such As Corner Radius And Cutting Edge Angle, Impact Its Wear Resistance?

The shape of a milling cutter affects how long it lasts while cutting. If the corners are rounded, they are less likely to chip or break. A good cutting edge angle helps the cutter slice easily through materials. This means it can stay sharp for longer, which is better for wear resistance. Overall, a well-designed cutter lasts longer.

What Role Does Cutting Fluid Or Lubrication Play In Enhancing The Corner Wear Resistance Of Milling Cutters During Operations?

Cutting fluid or lubrication helps cool down the milling cutter while it works. This cooling prevents the cutter from getting too hot and wearing out quickly. The fluid also makes it easier for the cutter to slide through the material. This means the corners last longer and can cut better for more time.