Have you ever wondered how manufacturers create strong and precise parts? It all starts with tools called milling cutters. These tools are essential in shaping materials. But what about the forces that act on them during cutting? We can map these cutting forces using a special tool known as a milling cutter cutting force map generator.

This generator helps engineers understand how much force is at play. Imagine trying to cut through a cake. If you push too hard, you might end up with a messy slice. The same idea applies to machining materials. Finding the right balance of cutting force is crucial for a clean and successful cut.

Studies show that knowing cutting forces can save time and resources. Isn’t that interesting? By using a milling cutter cutting force map generator, we can visualize these forces. This makes it easier to design better tools and improve the manufacturing process.

In this article, we will explore how this generator works and why it matters so much. Get ready to dive into a fascinating world where science meets creativity!

Milling Cutter Cutting Force Map Generator: An Overview

Milling Cutter Cutting Force Map Generator

Discover how the milling cutter cutting force map generator transforms machining processes. This tool helps predict cutting forces during milling operations, improving accuracy and efficiency. Imagine having a roadmap that shows where to apply more power and where to ease off. It can save time and reduce wear on equipment. With accurate force mapping, manufacturers can optimize their operations. This means better quality parts and less waste. Isn’t it amazing how technology can simplify complex tasks?Types of Milling Cutters

Description of different milling cutter types (end mills, face mills, etc.). Comparison of physical characteristics and performance metrics.Milling cutters come in different shapes and sizes, each designed for specific tasks. For example, end mills have sharp ends for precision cutting, while face mills cut flat surfaces. End mills are like the ninjas of machining, sneaking into tight spots! On the other hand, face mills act like bulldozers, flattening large areas in no time. Here’s a quick comparison to help you understand:

| Type | Shape | Best Use |

|---|---|---|

| End Mill | Pointed | Detail work! |

| Face Mill | Flat | Surface finishing |

Each cutter has its own secret superpowers. Knowing these differences helps in choosing the right tool for your mill. Choose wisely, and you’ll be the superhero of your workshop!

Importance of Cutting Force Maps

Explanation of cutting force maps and their applications in milling. Benefits of using cutting force maps for machining optimization.Cutting force maps show how much force is needed when cutting materials. They help in milling, a process to shape objects. These maps provide important insights about cutting conditions. This information allows makers to improve their methods. Benefits of using cutting force maps include:

- Better machine performance

- Less waste of materials

- Longer tool life

- Improved product quality

Using these maps can make a big difference in machining.

Why Are Cutting Force Maps Important?

The importance of cutting force maps lies in their role in helping manufacturers enhance efficiency. They provide data to optimize the cutting process. It leads to cost savings and higher quality products.

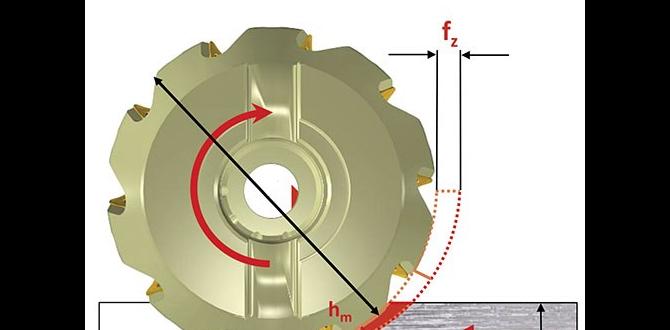

Components of a Cutting Force Map

Key elements typically included in a cutting force map (force components, angles, etc.). How these components influence milling performance.Understanding the key parts of a cutting force map is like solving a fun puzzle. First, we have force components, which tell us how much strength is needed during milling. Think of it as muscles doing all the heavy lifting! Then, there are angles that show how the cutter meets the material. This angle is like the secret handshake between the cutter and the workpiece. Both of these components greatly affect how well the milling performs. If the force is too high, it’s like trying to lift a giant donut; if the angle is wrong, it’s like hitting the wrong notes in a song!

| Component | Description |

|---|---|

| Force Components | Indicates strength needed for cutting. |

| Angles | Shows cutter’s position against the material. |

Software and Tools for Cutting Force Map Generation

Popular software packages used in the industry for generating cutting force maps. Comparison of features and ease of use among different tools.Many workers in the industry use software to create cutting force maps. These tools help understand how much force a milling cutter needs. Here are some popular ones:

- CAMotics: This tool is user-friendly and great for beginners.

- Mach3: It offers lots of features but can be complex.

- Fusion 360: A favorite among experts, known for its accuracy.

Comparing these tools shows differences in features and ease of use. Some are simpler, while others offer advanced capabilities for experienced users.

What is the best software for generating cutting force maps?

The best software can depend on your needs. Many choose Fusion 360 for its accuracy, while beginners prefer CAMotics. It’s important to find a tool that suits your skill level.

Case Studies: Successes in Force Map Implementation

Realworld examples of businesses that improved efficiency using cutting force maps. Lessons learned and best practices from these case studies.Many businesses have found success by using cutting force maps. For example, a machine shop in Chicago cut its production time by 30%! They used these maps to plan better and avoid problems. Another factory in Texas increased tool life by 25% just by studying their maps. They learned that knowing the right force saves money and time. Here are some key lessons:

| Business | Improvement | Lesson Learned |

|---|---|---|

| Chicago Machine Shop | 30% less time | Plan ahead! |

| Texas Factory | 25% more tool life | Know your force. |

These stories show that using cutting force maps can really pay off. Remember, it’s about working smarter, not harder. Who knew maps could lead to treasure in productivity?

Future Trends in Cutting Force Mapping Technology

Emerging technologies and their potential impact on cutting force map generation. Predictions for the future of milling process optimization through cutting force analysis.New technologies are changing the game for cutting force mapping. We may soon see advanced sensors that give more precise data. Artificial intelligence will also help analyze this data quickly. This could make milling processes faster and safer. Experts predict these tools will allow businesses to create better products with less waste. Every piece of information will matter in making improvements.

How will technology affect cutting force mapping?

Technology will lead to faster and more accurate cutting force maps. With better tools, manufacturers can make smarter decisions and improve their processes.

Key Predictions:

- Increased automation in milling processes

- More accurate force readings

- Smarter analysis through AI

Challenges in Cutting Force Map Generation

Common issues faced during the generation of cutting force maps. Strategies to mitigate these challenges for more accurate results.Generating cutting force maps can feel like trying to find a unicorn – tricky and elusive. Common challenges include fluctuating data and machine vibrations that distort results. You might even end up with maps that look like abstract art! To tackle these issues, use consistent testing conditions and high-quality sensors to capture vibrant data. Also, consider using software that smooths out noise. Trust me; your cutting force maps will thank you by looking much more professional!

| Challenge | Solution |

|---|---|

| Data Fluctuations | Consistent testing conditions |

| Machine Vibrations | High-quality sensors |

| Noisy Data | Use smoothing software |

Conclusion

In conclusion, a milling cutter cutting force map generator helps you understand how forces work during milling. It shows how different factors affect cutting performance. By using this tool, you can improve your machining results. We encourage you to explore this topic further and try using the generator in your projects. It can really boost your skills and knowledge!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Cutting Force Map Generators:Milling cutters are tools that help shape materials like metal or wood. Cutting force map generators show us how hard the cutter works. They help us see where the most strength is needed. This makes it easier to cut things correctly. You can think of it like a treasure map that shows the best path to take!

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Cutting Forces Generated During Milling Operations With Different Types Of Milling Cutters?When we use milling cutters, the cutting forces can change. First, the type of cutter matters. Some cutters are sharp, while others are thicker. The speed at which we move the cutter affects the force too. Finally, the material we cut, like wood or metal, also impacts the force needed.

How Can A Cutting Force Map Generator Assist In Optimizing Milling Parameters Such As Feed Rate, Depth Of Cut, And Spindle Speed?A cutting force map generator helps you see how different settings affect the machine’s work. For example, it shows how fast you should feed the material, how deep the cut should be, and how fast the spindle should spin. With this information, you can find the best settings for your job. This means you can cut better and save time. Using it makes your work easier and helps you get better results.

What Are The Key Components And Algorithms Used In Developing A Cutting Force Map Generator For Milling Operations?To make a cutting force map for milling, we need some important parts. First, we gather data about the tools and materials we are using. Next, we use calculations to predict how much force the tool will need when cutting. This involves special programs called algorithms, which help organize and analyze the data. By combining all this information, we can see where the tool will work best.

How Does The Geometry Of A Milling Cutter Affect The Resultant Cutting Forces During Machining Processes?The shape of a milling cutter changes how it cuts materials. If the cutter has sharp edges, it cuts easily and uses less force. A wider or flatter cutter might need more force to cut through. This means that how the cutter is designed can make our job easier or harder when machining materials.

What Role Does Simulation Software Play In Visualizing And Analyzing The Cutting Force Maps Generated For Different Milling Cutter Configurations?Simulation software helps us see and understand cutting force maps for milling machines. When we change cutter shapes, the software shows how these changes affect cutting strength. This way, we can choose the best cutter for our work. It also helps us find problems before we start cutting, making our work safer and smarter.