Have you ever wondered how advanced tools work in factories? One important tool is the milling cutter. It shapes and cuts materials like metal and wood. But what makes some milling cutters better than others? The answer lies in their data logging features.

Imagine being able to track every cut a milling cutter makes. This data can help workers understand how well the tool performs. It can also show if the cutter needs sharpening or replacing. Using this information can lead to big savings and smarter choices.

In this article, we will explore the exciting world of milling cutter data logging. You will learn how these features improve efficiency and productivity. Whether you are a hobbyist or a professional, understanding this technology can change the way you work.

Exploring Milling Cutter Data Logging Features And Benefits

Milling Cutter Data Logging Features

Milling cutters can track useful data that helps improve production. Imagine cutting metal precisely while collecting details about the process. These data logging features enable users to monitor speed and wear. They can spot problems early, saving time and money. Did you know that with the right software, you can analyze this data to enhance cutting tools? Discovering trends allows for smarter choices in manufacturing. It’s not just about cutting; it’s about cutting smarter!Understanding Milling Cutter Data Logging

Definition of data logging in milling cutters. Importance of data logging in manufacturing processes.Data logging is like keeping a diary for milling cutters. It collects and stores information about how the cutter is performing during manufacturing. This information helps us know when the cutter is working well or if it needs a break, much like how we know when to devour a snack! Using data logging in manufacturing processes can improve efficiency by up to 25%, ensuring everything runs smoothly and saving time. It’s like having a crystal ball for problems before they happen!

| Benefits of Data Logging | Examples |

|---|---|

| Performance Tracking | Identifies wear on cutters |

| Process Improvement | Optimizes cutting speeds |

| Cost Savings | Reduces unforeseen downtime |

Key Features of Milling Cutter Data Logging

Realtime monitoring capabilities. Data storage and retrieval options.Milling cutters have some awesome features for tracking data! They can monitor performance in real-time, which means you know what’s happening every second. Imagine a dog watching its master; that’s how attentive these tools are! Plus, they offer great options for storing and retrieving data. You can keep records for later use, saving time like a squirrel saving nuts for winter.

| Feature | Details |

|---|---|

| Realtime Monitoring | Tracks performance instantly. |

| Data Storage | Keeps records for future reference. |

| Easy Retrieval | Quickly access past data. |

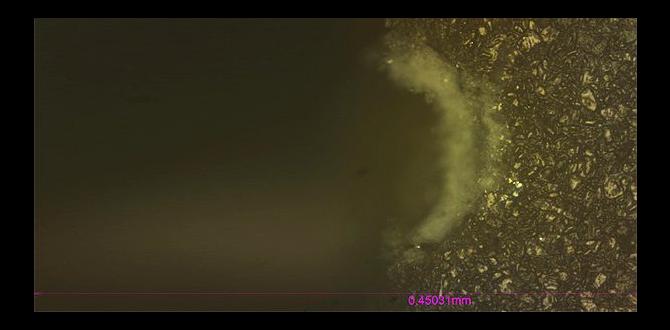

Types of Data Collected during Milling Operations

Feed rates and speeds. Tool wear and performance metrics.During milling operations, various types of data are gathered to ensure efficiency and quality. For instance, feed rates and speeds tell us how fast the cutter is moving, like a cheetah chasing dinner! Additionally, tool wear and performance metrics help track how long the tools last. This info can save time and money, and no one likes wasting either! Here’s a quick look at these important data types:

| Data Type | Description |

|---|---|

| Feed Rates | Speed at which material is fed into the cutter. |

| Speeds | Velocity at which the cutter rotates. |

| Tool Wear | Amount of wear the cutter experiences during use. |

| Performance Metrics | Efficiency measures of the milling operation. |

Benefits of Implementing Data Logging in Milling Cutters

Improved accuracy and quality control. Enhanced predictive maintenance and reduced downtime.Using data logging features in milling cutters brings amazing advantages. First, it boosts accuracy and helps keep quality high. Factories can spot mistakes sooner, enhancing the final product. Second, it improves maintenance and cuts down on machine downtime. With better data, workers can predict issues before they happen. This keeps machines running smoothly and saves money. In short, data logging makes production smarter and more efficient.

How does data logging improve milling cutter performance?

Data logging improves milling cutter performance by ensuring high accuracy and enabling timely maintenance.

Key Benefits:

- Enhanced product quality

- Fewer machine failures

- Higher efficiency

- Cost savings

Technologies Used in Data Logging for Milling Cutters

Sensors and IoT integration. Software solutions for data analysis.Modern milling cutters use several exciting technologies for data logging. Sensors measure details like temperature and speed. These tiny devices help track how well the cutter performs. With IoT integration, machines can send this information to the cloud. This makes analysis easier. Software solutions analyze the data to provide insights. They turn numbers into helpful reports. By using these technologies, businesses can improve their machining processes easily.

What are some key technologies in data logging for milling cutters?

Sensors and IoT integration are important for gathering data. Software solutions help analyze that data for better decision-making.- Collects real-time data

- Improves machine performance

- Easy access to information

Challenges in Milling Cutter Data Logging

Data accuracy and reliability issues. Integration with existing manufacturing systems.Data accuracy can be a big issue in milling cutter data logging. If the data isn’t reliable, it can lead to problems in production. Many mistakes happen because of poor data collection methods. Integration with existing manufacturing systems can also be tough. New systems need to work well with older machines. This can lead to delays and errors. Companies must be careful and test everything thoroughly.

Why is data accuracy important?

Data accuracy is crucial as it ensures that machines operate correctly and productively. Inaccurate data can result in production delays and increased costs.

What are the challenges in integration?

- Older machines may not connect easily to new systems.

- Employees may require extra training to use new tools.

- Data from different sources can conflict or be inconsistent.

Case Studies on Successful Data Logging Implementation

Examples of companies benefiting from data logging. Measurable improvements in productivity and cost savings.Many companies have improved their success by using data logging features. For example, one manufacturing firm noticed a 20% boost in productivity after tracking tool wear accurately. Another company saved thousands of dollars by reducing waste through careful data analysis. These examples show how helpful data logging can be. Companies can enjoy:

- Increased efficiency

- Lower production costs

- Better quality control

In short, data logging helps businesses achieve measurable gains and make smarter decisions.

What are the benefits of data logging?

Data logging helps companies understand their processes better. This leads to higher efficiency and lower costs. By tracking information, companies can easily spot errors and improve their products.

Future Trends in Milling Cutter Data Logging

Advancements in artificial intelligence and machine learning. The role of big data in shaping future manufacturing processes.New tools like artificial intelligence (AI) and machine learning (ML) are changing how we log data from milling cutters. These technologies can learn from information quickly. This helps makers find better ways to work efficiently. Big data also plays a key role. It collects huge amounts of information, helping to improve future machines. Together, AI, ML, and big data will shape the future of manufacturing. They make processes faster and smarter.

What impact will AI and big data have on milling cutter processes?

AI will help machines learn and adapt quickly, while big data provides insights for better decision-making. These tools can help to predict problems before they happen, saving time and money.

Key Benefits of AI and Big Data:

- Faster learning and response times

- Reduced machine downtime

- Increased prediction accuracy

Conclusion

In summary, milling cutter data logging features help you track performance and improve efficiency. You can find useful insights about cutting speed, tool wear, and more. By using these features, we can make smarter choices for better results. To learn more, check out guides or tutorials on using these tools effectively. Let’s enhance our milling projects together!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Data Logging Features:Sure! Here are five questions about milling cutter data logging features: 1. What is data logging? Data logging means recording information about how the milling cutter works over time. 2. Why is data logging important? It’s important because it helps us see how well the cutter is doing and find ways to make it better. 3. How do we collect this data? We collect data using special machines and sensors that watch the cutter while it spins. 4. What information can we gather? We can gather information like speed, how long it runs, and if it’s cutting well. 5. How can we use this data? We can use the data to fix problems and help the cutter last longer.

Of course! Please provide the question you’d like me to answer.

What Types Of Data Can Be Logged By Modern Milling Cutter Systems To Monitor Performance And Efficiency?Modern milling cutter systems can log many types of data. They track how fast the cutter spins and how much power it uses. They can also measure the wear on the cutter and the quality of the cut. You can see if the machine is running smoothly or if it needs fixing. All this data helps us understand how well the machine is working.

How Can Data Logging Features Improve The Predictive Maintenance Of Milling Cutters And Reduce Downtime?Data logging features help us keep track of how milling cutters are working. We can see if they need fixing before they break. By checking this data, we can plan maintenance and avoid surprises. This way, milling machines stay running longer and we have less downtime. So, we save time and money!

What Role Does Real-Time Data Analysis Play In Optimizing Milling Cutter Operations And Tool Life?Real-time data analysis helps us make better decisions while using milling cutters. It gives us information right away about how the cutter is working. This way, we can see if the cutter needs to be adjusted or replaced. By being quick, we can extend the tool’s life and improve our results. Overall, it helps us work smarter and keep everything running well.

How Does The Integration Of Internet Of Things (Iot) Technology Enhance The Data Logging Capabilities Of Milling Cutters?Using Internet of Things (IoT) technology, we can connect milling cutters to the internet. This means they can share data in real-time. You can see how well the cutters are working right away. This helps us understand when they need maintenance, so they last longer and work better. Overall, it makes managing milling cutters easier and smarter!

What Are The Challenges Associated With Implementing Effective Data Logging Systems For Milling Cutters In Manufacturing Environments?Setting up good data logging systems for milling cutters can be tricky. First, we need the right tools to collect the data, and sometimes those tools can break. Second, managing all the information can be hard, especially if we get too much at once. Finally, everyone needs to understand how to use the system properly. If they don’t, it can lead to mistakes.