Have you ever wondered how machines can cut metal so smoothly? One secret lies in a milling cutter designed for minimum quantity lubrication. This special tool works wonders by using just a tiny amount of oil. Imagine running a marathon, but only needing a sip of water to stay hydrated. That’s the beauty of this technology!

These milling cutters help factories save money and protect the environment. They make cutting easier and cleaner, using less oil while still getting the job done. Isn’t it amazing how something so small can have such a big impact?

In this article, we will dive deeper into how these tools work and why they are important. You’ll discover some fun facts and stories that show the power of innovation. So, let’s jump in and explore the world of milling cutters designed for minimum quantity lubrication!

Milling Cutter Designed For Minimum Quantity Lubrication Solutions

Milling Cutter Designed for Minimum Quantity Lubrication

Milling cutters designed for minimum quantity lubrication (MQL) are innovative tools. They use less oil, which makes them eco-friendly and cost-effective. You’ll discover how these cutters improve machining efficiency while reducing waste. Did you know using MQL can extend tool life and enhance surface finish? This means better quality products with fewer resources. As industries focus on sustainability, these advanced milling cutters play a crucial role in modern manufacturing practices.What is Minimum Quantity Lubrication (MQL)?

Definition and principles of MQL. Advantages of utilizing MQL in machining processes.Minimum quantity lubrication (MQL) is a machining technique that uses only a small amount of coolant. This helps to cool and lubricate cutting tools while machining metal. The principles of MQL focus on efficiency and reduced waste. Instead of flooding the area with liquid, MQL applies just enough lubricant for effective cooling.

The advantages of using MQL include:

- Reduced waste – Less fluid means less mess.

- Lower costs – Less lubricant saves money.

- Cleaner work environment – Less coolant leads to a tidier space.

- Better tool life – Tools last longer with proper lubrication.

This method is growing in popularity, making machining more efficient and eco-friendly.

What are the benefits of MQL?

The benefits of MQL include reduced waste, lower costs, and longer tool life.Benefits of Using MQL with Milling Cutters

Enhanced tool life and performance. Environmental and economic advantages of MQL.Using minimal quantity lubrication (MQL) with milling cutters has some truly awesome benefits! For starters, it can boost tool life significantly. Think of it as giving your tools a spa day—less friction means they last longer! Plus, MQL saves money and helps the planet by using less oil. So, it’s like saving cash while saving trees! Here’s a fun fact: tools can last up to 50% longer when using MQL. That sounds like a winning combo!

| Benefits | Details |

|---|---|

| Enhanced Tool Life | Can last up to 50% longer with MQL |

| Eco-Friendly | Uses less oil, reducing waste |

| Cost-Effective | Saves money on oil and tool replacements |

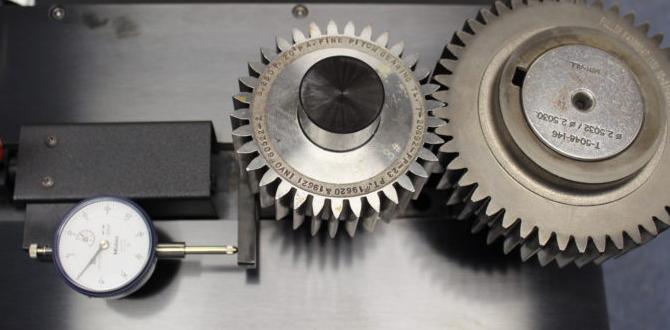

Factors to Consider When Selecting MQL Milling Cutters

Material composition and geometry of milling cutters. Compatibility with machining processes and materials.Choosing the right milling cutter is important. Material composition affects strength and durability. For example, cutters made from carbide last longer but cost more. The geometry of the cutter influences cutting speed and accuracy. Consider how the cutter works with your machines and materials. Each machine has different needs, so check compatibility. A good match ensures smooth operation. Asking questions can lead to better choices.

What should I consider when choosing a milling cutter?

Focus on the material and shape of the cutter and how it fits with your tools. Here are some key points:

- Material composition affects cutter life.

- Geometry influences cutting efficiency.

- Compatibility ensures smooth machining.

How to Implement MQL with Milling Cutters

Required equipment and setup for MQL. Best practices for optimal MQL performance in milling operations.Setting up for Minimum Quantity Lubrication (MQL) in milling is easy peasy! First, you need a suitable milling cutter. A high-speed spindle works wonders, too. Next, look for a tight-fitting nozzle to deliver that magical mist. Proper placement is key to reduce waste. Then, embrace the right lubricant. Choose a good one that won’t break the bank. Follow these best practices: keep the pressure on low but steady, and use small amounts of lube. It’ll keep your cutter happy and work like a charm!

| Equipment | Purpose |

|---|---|

| Milling Cutter | For precise cutting |

| Nozzle | Delivers MQL |

| Lubricant | Reduces friction |

Challenges and Considerations in MQL Milling

Common issues faced when using MQL. Ways to troubleshoot and optimize MQL usage.Using MQL in milling can feel like trying to teach a cat to swim. Common issues pop up, like inconsistent lubrication or strange sounds from your machine. But fear not! Troubleshooting can be simpler than you think. Check if the oil is mixed well or if the nozzle is clogged. Making adjustments can boost efficiency and keep your machine happy. Here’s a quick look at factors to consider:

| Common Issues | Solutions |

|---|---|

| Inconsistent lubrication | Mix oil properly, check nozzles |

| Strange machine noises | Inspect parts for wear |

| Tool wear | Optimize cutting speed |

With these tips, you’ll master MQL milling in no time, kind of like turning a cranky cat into a playful pup!

Future Trends in MQL and Milling Cutter Development

Innovations in milling cutter technology for MQL. The future landscape of machining with MQL techniques.Exciting changes are coming to milling cutters, especially for those designed for minimum quantity lubrication (MQL). New technologies will make milling more efficient and eco-friendly. Imagine cutting metal while using less oil—like dressing up a burger with a sprinkle of salt instead of drowning it in ketchup! These innovations will help machines run smoother and save money.

| Innovations | Benefits |

|---|---|

| Advanced Coatings | Less wear and tear on cutters. |

| Smart Sensors | Optimal lubrication control. |

| Eco-Friendly Materials | Safer for the planet. |

In the future, machining will look very different with MQL. Expect less waste and more precise cuts. As they say, “Less is more,” especially when it comes to oil!

Conclusion

In summary, a milling cutter designed for minimum quantity lubrication helps you cut more efficiently. It reduces oil use and keeps parts cool. This saves money and improves your work quality. If you want to learn more about this technology, explore related articles or talk to experts. Remember, using the right tools makes your tasks easier and better!FAQs

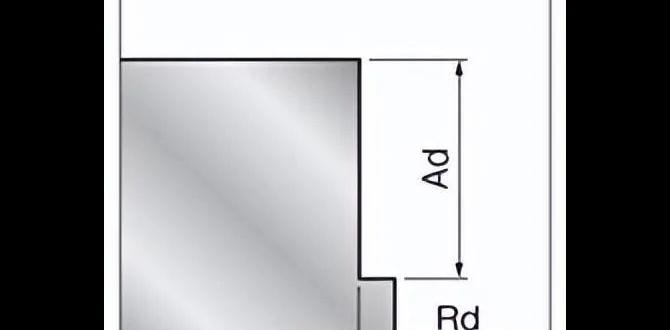

What Are The Key Design Features Of Milling Cutters That Enable Effective Performance Under Minimum Quantity Lubrication (Mql) Conditions?Milling cutters used with minimum quantity lubrication (MQL) have special designs. They often have sharp edges to cut easily. Smooth surfaces help reduce friction, making them work better. Some have special shapes that allow oil to reach the cutting area easily. These features help the cutter stay cool and last longer.

Sure! Please go ahead and ask your question.

How Does The Use Of Minimum Quantity Lubrication During Milling Affect Tool Wear And Overall Tool Life Compared To Traditional Lubrication Methods?Using minimum quantity lubrication during milling helps keep tools cool and reduces friction. This means tools don’t wear out as quickly. In contrast, traditional methods use more oil, which can create a mess and doesn’t always help as much. So, with less oil, we can make tools last longer and work better. Overall, it’s a cleaner and smarter way to do the job!

Sure! Please provide the question you want me to answer, and I’ll be happy to help!

What Materials And Coatings Are Commonly Used In The Manufacturing Of Milling Cutters Designed For Minimum Quantity Lubrication Applications?Milling cutters for minimum quantity lubrication, or MQL, use special materials like high-speed steel and carbide. These materials are strong and last a long time. We often cover these cutters with coatings like titanium nitride or cobalt to make them even tougher. This helps them work better and stay sharp while using little oil.

Sure! Please provide the question you’d like me to answer.

In What Types Of Milling Operations Or Materials Is Minimum Quantity Lubrication Most Beneficial, And Why?Minimum quantity lubrication, or MQL, works best for hard materials like metals and during milling. MQL uses very little oil, which helps keep parts cool. This is important because it stops pieces from getting too hot and breaking. We save oil and make less mess while working!

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.

What Are The Environmental And Economic Advantages Of Using Milling Cutters Optimized For Minimum Quantity Lubrication In Industrial Machining Processes?Using special milling cutters with minimum quantity lubrication (MQL) helps the environment. They use less coolant, which means less waste to clean up. This is good for our planet. Economically, these cutters save money because they need less coolant and last longer. When we use them, we spend less on materials and reduce our costs.