Have you ever wondered how a milling cutter handles tough jobs? Imagine a small tool spinning at high speed, effortlessly slicing through metal. That’s the milling cutter, a hero in the world of machining. But what happens when this tool faces different forces during work? This is where the concept of dynamic load response comes in. It’s like asking how a player adjusts when the game gets intense.

When a milling cutter works, it doesn’t just cut evenly. It feels the pressure, vibrations, and sudden changes in speed. This means the cutter must be strong and smart. Understanding how it reacts to these challenges can help engineers make better tools and keep machines running smoothly.

Did you know that the right design can make a huge difference in performance? Just like athletes train for different events, milling cutters are designed for specific tasks. By exploring their dynamic load response, we can learn a lot about their performance and lifespan.

Are you ready to dive deeper into the world of milling cutters? Let’s discover how they react to challenges, and why this matters to everyone who uses them!

Milling Cutter Dynamic Load Response: An In-Depth Analysis

Milling cutter dynamic load response refers to how these tools react under different stress levels during cutting. Understanding this helps improve performance and lifespan. Have you ever wondered why some tools wear out quickly? It often comes down to how they handle loads. By studying their responses, engineers can design better cutters that manage forces effectively. This knowledge ensures smoother operations and efficient machining. Your work can benefit from these insights, leading to stronger tools and high-quality results!

Understanding Dynamic Load in Milling Operations

Definition of dynamic load and its significance in machining.. Factors influencing dynamic load during milling processes..

Dynamic load refers to the forces that act on a milling cutter while it cuts through materials. This load changes quickly due to vibrations or tool changes. It’s important because it affects how long tools last and how well they perform. Many factors can influence this load, including:

- Tool speed: Faster speeds can increase vibration.

- Material type: Harder materials create more load.

- Cut depth: A deeper cut raises the dynamic load.

- Tool shape: Different shapes impact how the load is distributed.

Understanding these factors helps improve machining quality and efficiency.

What is dynamic load?

Dynamic load is the variable force acting on the milling cutter during machining. It influences the cutter’s performance and lifespan.

Factors Affecting Dynamic Load Response in Milling Cutters

Material properties of milling cutters and workpieces.. Impact of cutting speed, feed rate, and depth of cut..

Several factors can impact how milling cutters handle dynamic loads. First, the material properties of both the cutter and the workpiece play a big role. Harder materials can resist deformation, but they may also be more brittle. Next, cutting speed is crucial. Faster speeds often increase heat, which can lead to faster wear. Lastly, feed rate and depth of cut must be just right. Too deep or fast, and your cutter might throw a tantrum, sending sparks and chips flying everywhere!

| Factor | Impact |

|---|---|

| Material Properties | Hardness affects wear resistance |

| Cutting Speed | High speeds increase heat |

| Feed Rate | Faster feed can cause excess load |

| Depth of Cut | Deeper cuts increase cutting force |

Analyzing the Dynamic Behavior of Milling Cutters

Description of analytical and experimental methods used for analysis.. Case studies on dynamic behavior in realworld applications..

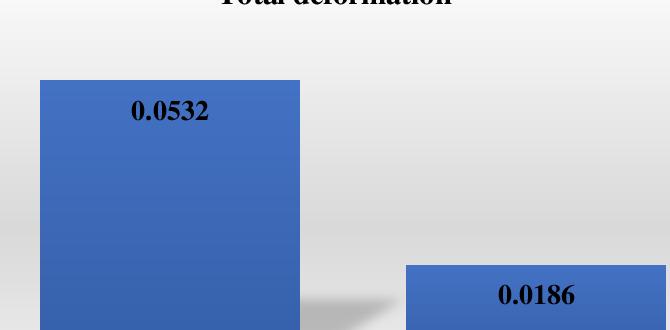

Understanding how milling cutters behave is important for better performance. Engineers use both analytical and experimental methods to study this behavior. Analytical methods involve math and models to predict how a cutting tool will react. In contrast, experimental methods test real tools in real situations to see how they perform.

In many case studies, researchers observe dynamic responses in actual manufacturing settings. These findings help improve design and efficiency. Here’s a quick summary of common methods:

- Finite Element Analysis: A computer-based method to simulate cutting conditions.

- Modal Testing: Measures how tools respond to vibrations.

- Field Testing: Uses real-world data to validate analytical models.

What are common methods used to analyze milling cutters?

Engineers typically use Finite Element Analysis, Modal Testing, and Field Testing to study milling cutters’ dynamic behavior.

Optimizing Milling Cutter Performance Under Dynamic Loads

Techniques for optimizing cutter geometry to reduce dynamic loads.. Best practices for machining parameters to enhance cutter stability..

Using the right cutter geometry is like putting on your favorite shoes. Too tight, and it won’t work. Too loose, and you might trip! Adjust the angles and sizes of milling cutters to cut down on pesky dynamic loads. This can lead to better stability. Also, consider your machining parameters. Optimal speed and feed rates help keep vibrations at bay. Remember, smoother cuts mean fewer headaches! Check out this handy table:

| Cutter Geometry Adjustments | Best Machining Practices |

|---|---|

| Sharp edges reduce friction. | Choose moderate speeds. |

| Balanced shapes improve stability. | Use proper tool paths. |

| Tweaked angles enhance cutting. | Watch those feed rates! |

With these tips, your milling cutter will dance through materials like a pro! Who said manufacturing can’t be fun?

The Role of Vibration in Milling Cutter Performance

Explanation of how vibrations affect cutting efficiency and cutter life.. Methods of measuring and mitigating vibrations during milling..

Vibrations can make milling cutters work poorly. They reduce cutting efficiency and shorten the cutter’s life. When a cutter shakes too much, it can cause bad cuts. This wastes time and materials. Measuring vibrations helps us understand these problems. We can use tools like accelerometers to find out how much a cutter vibrates. We can also reduce vibrations by changing the cutter’s speed or using dampeners. This keeps the cutter healthy and makes work easier.

How do vibrations impact cutting efficiency?

Vibrations can lead to bad cuts, lower speeds, and quicker tool wear. Cutting too hard or fast can make vibrations worse. This leads to wasted time and bad quality.

Methods to measure and reduce vibrations

- Use accelerometers to measure vibrations.

- Adjust cutter speed for better performance.

- Incorporate dampeners to absorb shocks.

Future Trends in Milling Cutter Design and Technology

Innovations in materials and designs that enhance load response.. Predictions for future advancements in milling cutter technology..

Exciting changes are on the horizon for milling cutters! Engineers are discovering new materials that make cutters stronger and lighter. Just imagine cutting through metal like butter! Innovations like composite materials and clever designs help milling cutters handle heavy loads without breaking a sweat.

In the future, we can expect even bolder advancements. Researchers predict smarter milling cutters will be designed with sensors that can talk to machines. They might even adjust themselves based on the job! Now, that’s a team player!

| Innovation | Description |

|---|---|

| Composite materials | Stronger and lighter material for better performance. |

| Smart sensors | Adjust cutter response based on workload. |

Get ready, because the future sounds thrilling for milling cutter technology!

Conclusion

In conclusion, understanding milling cutter dynamic load response helps improve machining efficiency. You learn how cutters react to forces during operation. This knowledge allows you to choose the right tools and settings. To dive deeper, explore resources on tool materials and cutting speeds. By doing this, you can enhance your skills and achieve better results in your projects.

FAQs

What Factors Influence The Dynamic Load Response Of Milling Cutters During Machining Operations?

The dynamic load response of milling cutters is affected by several factors. First, the speed of the cutter matters; faster speeds can cause more vibrations. Second, the type of material we are cutting can change how the cutter reacts. Also, the shape and sharpness of the cutter play a big role in how it cuts. Finally, the way we hold the cutter and machine also impacts how it performs.

How Can The Dynamic Behavior Of Milling Cutters Affect Surface Quality And Precision In Machining Processes?

The way milling cutters move can change how smooth or rough a surface is. If the cutter wobbles or shakes, it can leave bumps on the surface. This makes the piece not fit well with other parts. For good results, we need the cutter to move steadily and smoothly. That way, we get nice-looking and precise shapes.

What Are The Common Methods For Modeling And Analyzing The Dynamic Load Response Of Milling Cutters?

To study how milling cutters react when they cut materials, we use different methods. One common way is to create computer models that simulate how cutters move and work. We can also run tests in a lab to see how the cutters behave with real materials. Another method is to use special sensors to measure forces while cutting. These methods help us understand and improve cutting tools better.

How Do Variations In Cutting Speed, Feed Rate, And Tool Geometry Impact The Dynamic Load Response Of Milling Cutters?

When you change the cutting speed, feed rate, and tool shape, it affects how the milling cutter works. Faster speeds can make the cutter vibrate more. If you push the cutter harder (higher feed rate), it can also cause more strain. Different shapes of the tool can change how it cuts through the material. All these changes impact how well the cutter stays steady while working.

What Role Does The Material Composition Of Milling Cutters Play In Their Ability To Withstand Dynamic Loads During Operation?

The material of milling cutters affects how strong and tough they are. Stronger materials can handle heavy forces while cutting. If the material is weak, it can break or wear out quickly. So, choosing the right material helps the cutter last longer and work better. You want your tools to be tough for the job!