Have you ever wondered how to make your milling cutter work better? One way is by exploring milling cutter edge pre-treatment options. These treatments prepare the cutter’s edges to last longer and cut smoother. Imagine you are trying to slice a cake with a dull knife. It just doesn’t work well, right?

In the world of machining, a sharp, well-treated edge can make all the difference. Studies show that pre-treated milling cutters can improve the quality of your work. This small step can lead to big results!

So, what are the different pre-treatment options? Why should we care about them? These questions lead to exciting answers. Join us as we dive deeper into how these options can change your machining projects for the better.

Milling Cutter Edge Pre-Treatment Options: A Comprehensive Guide

Milling Cutter Edge Pre-Treatment Options

Milling cutter edge pre-treatment options are crucial for enhancing tool performance. Did you know that a well-prepared edge can extend tool life significantly? Techniques like coatings, grinding, and honing improve the cutter’s durability and efficiency. This means smoother cuts and less wear over time. Choosing the right pre-treatment can also save you money and time during production. Explore these methods to get the best results from your milling cutters!Understanding Milling Cutters

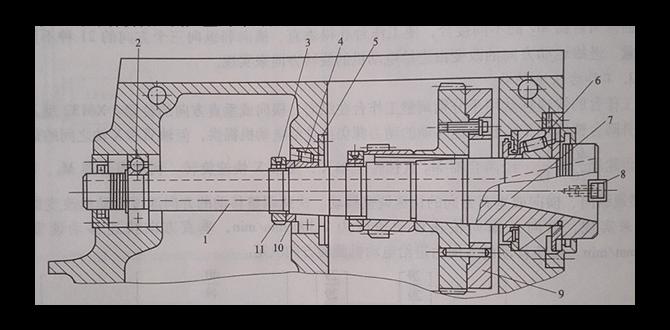

Definition and function of milling cutters in machining. Types of milling cutters commonly used in industrial applications.Milling cutters are sharp tools used in machining to carve out shapes from materials like metal and wood. They work like magic scissors, snipping away extra bits to make parts fit just right. There are various types of milling cutters, each with its own special job. For example, end mills are perfect for drilling holes, while slab mills are great for flat surfaces. Let’s look at some common types:

| Type of Milling Cutter | Function |

|---|---|

| End Mill | Used for drilling and contouring |

| Slab Mill | Ideal for flattening surfaces |

| Face Mill | Great for large flat areas |

These cutters help create everything from toys to cars. It’s like having a chef with special knives for every ingredient! Remember, having the right cutter makes all the difference in machining. After all, you wouldn’t slice bread with a butter knife, would you?

The Importance of Edge Pre-Treatment

Impact of edge pretreatment on tool performance. Benefits of enhanced wear resistance and cutting efficiency.Taking care of tool edges is like feeding your pet—miss a meal, and you’ll have a grumpy animal on your hands! Edge pretreatment boosts tool performance by enhancing wear resistance and cutting efficiency. With strong edges, tools cut smoother and longer. This means less time sharpening and more time creating! Plus, happy edges mean less wear and tear, saving you money in the long run. Think of it as giving your tools a superhero cape!

| Benefit | Description |

|---|---|

| Wear Resistance | Tools last longer and need fewer replacements. |

| Cutting Efficiency | Smoother cuts lead to better results and less effort. |

Coating Options for Milling Cutters

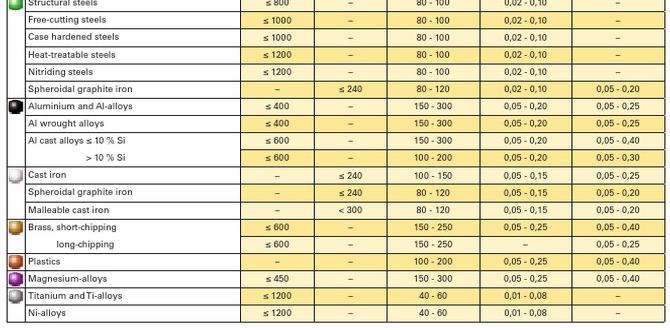

Description of various coatings (TiN, TiAlN, etc.) and their properties. Benefits and drawbacks of each coating type.Milling cutters use different coatings to improve their performance. Each coating has unique properties that help in various ways. Here are some common options:

- TiN (Titanium Nitride): This coating is hard and wear-resistant. It helps tools last longer but can be brittle.

- TiAlN (Titanium Aluminum Nitride): This one handles heat really well. It is great for high-speed cutting but may cost more.

- CrN (Chromium Nitride): This coating resists corrosion and is tough. However, it might not be as hard as Ti coatings.

Choosing the right coating can make a difference. Think about what the job needs. Some coatings are better for speed, while others help with durability.

What is the best coating for milling cutters?

The best coating depends on your project needs. If you are cutting tough materials, consider TiAlN for heat resistance. For general tasks, TiN is a solid choice.

Sharpening Techniques for Optimal Performance

Different methods of sharpening (grinding, honing, etc.). Best practices for achieving precise edge geometry.Sharpening milling cutters keeps them strong and efficient. There are several popular methods to make those edges shine. For instance, grinding uses wheels to shape the tool, while honing smooths the edges for a sharp finish. Following best practices helps maintain the perfect edge geometry. Remember, a well-shaped edge is like a sharp pencil—ready to write great stories!

| Method | Description | Best Use |

|---|---|---|

| Grinding | Shapes the edge with wheel abrasives. | Rough shaping or major repairs. |

| Honing | Smoothes the edge for precision. | Final touch for sharpness. |

Innovative Technologies in Edge Pre-Treatment

Emerging trends in pretreatment technology (e.g., laser treatment). Case studies demonstrating improved performance through advanced techniques.New technologies are making edge pretreatment exciting. One example is laser treatment. It uses focused light to improve cutter edges. This method helps to make them tougher and last longer. Case studies have shown great results. For instance, manufacturers noted a 30% boost in cutting speed with laser-treated tools. Here are some key points:

- Laser treatment enhances durability.

- Advanced techniques speed up production.

- Investing in technology can result in savings.

What are the benefits of laser treatment?

Laser treatment improves performance. It makes tools sharper and increases their lifespan. Many companies see faster production and less downtime due to tool wear.

Choosing the Right Pre-Treatment for Your Application

Factors to consider based on material and machining requirements. Guideline for selecting the most suitable pretreatment option.Choosing the right pre-treatment for your milling cutter is like picking the best topping for your pizza. It depends on what you have on hand! Consider the material you’re working with and how you plan to use the cutter. For softer metals, a simple cleaning might do, while tougher materials could need a deeper treatment. Remember, the goal is to improve performance without creating a donut hole in your budget.

| Material Type | Recommended Pre-treatment |

|---|---|

| Aluminum | Light cleaning |

| Steel | Coating or polishing |

| Stainless Steel | Passivation |

Finding the right fit ensures your cutter lasts longer and works better. It’s like wearing the right shoes for running. Slip on a pair of high-tops for basketball, and you might trip! So, think carefully before diving in.

Cost vs. Benefit Analysis of Pre-Treatment Options

Evaluation of the economic implications of pretreatments. Longterm savings associated with using treated edges in milling operations.Evaluating the costs and benefits of pretreatment options is crucial for smart milling. It may seem pricey upfront, but think of it as an investment in your tools. Treated edges can actually save money over time. They last longer, which means fewer replacements and less downtime. Imagine having a super tool that works like a charm all day! Plus, increased efficiency means more chips in your pocket.

| Cost of Pretreatment | Long-term Savings |

|---|---|

| $100 per cutter | $500 saved over time |

| Time spent on maintenance | Less frequent replacements |

In short, spending on pre-treating your milling cutter edges can be worth it. It’s not just about pennies now but about big bucks later!

FAQs About Milling Cutter Edge Pre-Treatment

Common questions regarding the effectiveness and methods of pretreatment. Expert answers to enhance understanding and application of pretreatment strategies.Many people wonder about milling cutter edge pretreatment. It’s important to know how effective these methods are. Here are some common questions and clear answers:

What are the benefits of edge pretreatment?

Edge pretreatment can improve tool life and reduce wear. This helps cutters stay sharp longer. Using pretreatment also enhances performance.

What methods are used for pretreatment?

- Coating with materials like titanium or ceramic.

- Mechanical treatments such as shot peening.

- Chemical treatments that remove impurities.

Understanding these options can help you choose the best method. When tools work better, they make tasks easier and safer.

Conclusion

In summary, milling cutter edge pre-treatment options improve tool performance and lifespan. We learned about different methods like coating and grinding. Choosing the right option helps you achieve better results in your projects. For better performance in your work, consider these treatments next time you use milling cutters. Keep exploring and learning for even more tips on tool maintenance!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Edge Pre-Treatment Options:Sure! Pre-treating milling cutter edges makes them better for cutting. You can sharpen them, change their shape, or coat them with special materials. These treatments help the cutters last longer and work better. It’s important to choose the right method for the job.

Sure! Please give me the question you want me to answer, and I’ll do my best to help you.

What Are The Most Common Milling Cutter Edge Pre-Treatment Methods, And How Do They Influence Tool Performance?Some common ways to prepare milling cutter edges include coating, sharpening, and grinding. Coatings help reduce friction and make the tool last longer. Sharpening gives a sharper edge for better cuts. Grinding smooths the edge, making it more precise. All these methods make the tool perform better and cut faster.

How Do Various Pre-Treatment Processes, Such As Coating Or Sharpening, Affect The Wear Resistance Of Milling Cutters?When we treat milling cutters, they last longer. Coating them with special materials makes them harder and helps them resist wear. Sharpening gives them a nice, sharp edge that cuts better. Both ways help the cutters work well and reduce how quickly they get worn down. So, treating them is really important for their strength!

In What Ways Can Edge Pre-Treatment Contribute To Improved Precision In Machining Operations?Edge pre-treatment helps make cuts in materials cleaner and more accurate. When we smooth the edges first, tools can work better. This means less waste and better shapes. You get a final product that fits perfectly and looks nicer. Overall, it makes our work faster and easier!

What Role Does The Material Composition Of Milling Cutters Play In Determining The Most Effective Edge Pre-Treatment Options?The material of the milling cutter affects how well it cuts. Different materials need different ways to prepare their edges. For example, a harder cutter might need a special sharpening method. This helps the cutter work better and last longer. So, the right edge treatment depends on the cutter’s material.

How Do Advancements In Edge Pre-Treatment Technologies Impact The Longevity And Efficiency Of Milling Operations In Industrial Applications?Advancements in edge pre-treatment technologies help make milling machines last longer and work better. These new techniques treat the edges of materials before we start milling. This means less wear and tear on the machines, so they don’t break down as often. When machines run smoothly, they can cut materials faster and more accurately. This all saves time and money for businesses!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Edge Pre-Treatment Options:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Pre-treating milling cutter edges makes them better for cutting. You can sharpen them, change their shape, or coat them with special materials. These treatments help the cutters last longer and work better. It’s important to choose the right method for the job.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer, and I’ll do my best to help you.”}},{“@type”: “Question”,”name”: “What Are The Most Common Milling Cutter Edge Pre-Treatment Methods, And How Do They Influence Tool Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some common ways to prepare milling cutter edges include coating, sharpening, and grinding. Coatings help reduce friction and make the tool last longer. Sharpening gives a sharper edge for better cuts. Grinding smooths the edge, making it more precise. All these methods make the tool perform better and cut faster.”}},{“@type”: “Question”,”name”: “How Do Various Pre-Treatment Processes, Such As Coating Or Sharpening, Affect The Wear Resistance Of Milling Cutters?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we treat milling cutters, they last longer. Coating them with special materials makes them harder and helps them resist wear. Sharpening gives them a nice, sharp edge that cuts better. Both ways help the cutters work well and reduce how quickly they get worn down. So, treating them is really important for their strength!”}},{“@type”: “Question”,”name”: “In What Ways Can Edge Pre-Treatment Contribute To Improved Precision In Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Edge pre-treatment helps make cuts in materials cleaner and more accurate. When we smooth the edges first, tools can work better. This means less waste and better shapes. You get a final product that fits perfectly and looks nicer. Overall, it makes our work faster and easier!”}},{“@type”: “Question”,”name”: “What Role Does The Material Composition Of Milling Cutters Play In Determining The Most Effective Edge Pre-Treatment Options?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material of the milling cutter affects how well it cuts. Different materials need different ways to prepare their edges. For example, a harder cutter might need a special sharpening method. This helps the cutter work better and last longer. So, the right edge treatment depends on the cutter’s material.”}},{“@type”: “Question”,”name”: “How Do Advancements In Edge Pre-Treatment Technologies Impact The Longevity And Efficiency Of Milling Operations In Industrial Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advancements in edge pre-treatment technologies help make milling machines last longer and work better. These new techniques treat the edges of materials before we start milling. This means less wear and tear on the machines, so they don’t break down as often. When machines run smoothly, they can cut materials faster and more accurately. This all saves time and money for businesses!”}}]}