Have you ever wondered how a tiny change can make a big difference in manufacturing? Imagine trying to cut a cake with a dull knife. It just doesn’t work, right? The same idea applies to milling cutter edge preparation standards.

Milling cutters help shape materials in factories. They need sharp edges to do their job well. If the edges are not prepared correctly, it leads to poor cuts. Poor cuts waste time and material. So, what’s the secret behind the best milling cutter edges?

Standards for edge preparation are there to help manufacturers. These rules ensure that every cutting tool is sharp and ready for action. By using these standards, companies can save money and improve their products.

Let’s dive deeper into the world of milling cutter edge preparation standards. You may find surprising facts that could change how you think about cutting tools!

Milling Cutter Edge Preparation Standards: Essential Guidelines

Milling Cutter Edge Preparation Standards

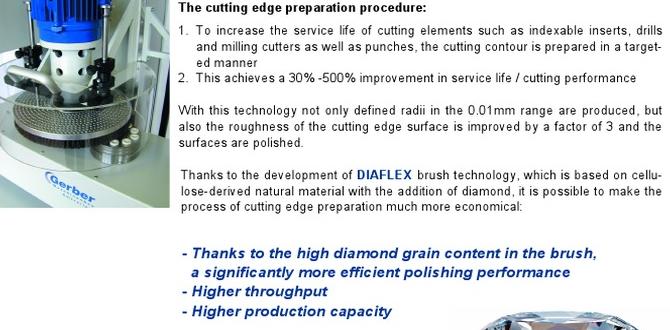

Milling cutter edge preparation standards ensure better cutting performance and longer tool life. Did you know that the shape and sharpness of a milling cutter can affect its efficiency? Proper edge preparation reduces friction and improves chip removal, leading to higher precision in machining. Different materials require specific edge treatments. Understanding these standards can help manufacturers choose the right cutter, ultimately saving time and resources. Embracing these guidelines can transform your milling processes!Understanding Milling Cutters

Definition and types of milling cutters. Importance of edge preparation in milling operations.Milling cutters are special tools that help shape materials like metal and wood. They come in different types, such as end mills and face mills. Each type has its own job, just like a superhero with a unique power! Edge preparation is very important for these cutters. Well-prepared edges help them slice through materials smoothly and last longer. If not, it’s like trying to spread butter with a spoon—messy and not very effective!

| Type of Milling Cutter | Best For |

|---|---|

| End Mill | Creating precise cuts |

| Face Mill | Flat surfaces and large areas |

| Ball Nose Mill | Curved and complex shapes |

Ensuring the right edge shape can mean the difference between a clean cut and a jammed machine. So, always remember: smooth edges equal smooth journeys!

Benefits of Proper Edge Preparation

Enhancements in tool life and performance. Impact on finished product quality.Proper edge preparation makes tools last longer and work better. Think of it as giving your tools a refreshing spa day! When the edges are sharp and correctly shaped, they cut more smoothly and need less effort. This can also mean less wear and tear. Plus, a well-prepared edge can improve the quality of the final product. If the edges are rough, you might end up with jagged results—like a cake that looks like it had a fight with a wild animal!

| Benefit | Impact |

|---|---|

| Tool Life | Increases significantly |

| Performance | Smoother cutting action |

| Product Quality | Fewer defects |

Challenges in Edge Preparation

Common issues faced during preparation. Solutions and best practices to overcome these challenges.Edge preparation can feel like a comedy of errors. Common issues include uneven surfaces and incorrect angles. Ever tried cutting a cake with a spoon? That’s how rough edges act in milling. But fear not! To tackle these challenges, regular inspection and correct tools are key. Use sharpening guides to keep edges just right. With a little humor and practice, your milling adventures can be smooth sailing!

| Common Issues | Solutions |

|---|---|

| Uneven surfaces | Inspect regularly and adjust settings |

| Incorrect angles | Utilize sharpening guides |

Future Trends in Edge Preparation Standards

Innovations and technological advancements in milling cutters. Predictions for future standards and practices in the industry.New ideas in milling cutter edge preparation are popping up like popcorn at a movie theater! Just imagine faster and sharper tools that can slice through tough materials. Innovations in materials and designs will set new standards for the industry. Experts predict more efficient practices will save time and money, making everyone’s life easier. Buckle up—this is one exciting ride into the future of milling!

| Innovation | Impact |

|---|---|

| Advanced Coatings | Increased Durability |

| Smart Sensors | Real-Time Monitoring |

| Eco-Friendly Materials | Less Waste |

Conclusion

In summary, milling cutter edge preparation standards are essential for better cutting performance. These standards help ensure accuracy and efficiency in machining. By understanding and applying these practices, you can improve your work. We encourage you to explore more about these standards and consider how they can benefit your projects. Dive deeper and sharpen your skills today!FAQs

Certainly! Here Are Five Related Questions On Milling Cutter Edge Preparation Standards:Sure! Milling cutters are tools that help shape materials like metal or wood. Edge preparation means getting the cutting edges ready for use. We want these edges to be sharp and smooth. This helps the cutters work better and last longer. Taking care of the edges is very important for good results!

Sure! Please go ahead and ask your question. I’m here to help!

What Are The Specific Edge Preparation Standards Commonly Used For Milling Cutters In Industrial Applications?Milling cutters are tools used to shape materials. We often prepare their edges in specific ways. Two common standards are “flat” and “radius” edges. Flat edges are sharp and straight, while radius edges have a small curve. These shapes help the cutter work better and last longer.

How Does The Edge Preparation Of A Milling Cutter Affect The Overall Performance And Tool Life During Machining Operations?The edge preparation of a milling cutter is very important. If the edges are sharp and smooth, the cutter works better and lasts longer. This means you can cut materials more easily without the tool getting damaged. When edges are not well prepared, the tool can wear out quickly, and you might need to replace it more often. So, good edge preparation helps you save money and do a better job!

What Are The Differences Between Common Edge Preparation Methods, Such As Honing, Chamfering, And Polishing, And How Do They Impact Cutting Efficiency?Honing makes the edge very smooth, helping it cut better. Chamfering gives the edge a slanted tip, which can prevent chipping. Polishing makes the edge shiny and also smooth. Each method helps tools cut more easily but in different ways. Using the right method can make your cutting tasks faster and cleaner.

In What Ways Do Different Materials Used In Milling Cutters Necessitate Variations In Edge Preparation Standards?Different materials for milling cutters, like steel or carbide, change how we prepare their edges. Harder materials might need sharper edges to cut better. Softer materials can work with blunter edges. Each type of material behaves differently during cutting. So, we adjust edge preparation for the best results.

How Can Adherence To Industry Standards For Milling Cutter Edge Preparation Improve Safety And Reduce The Risk Of Tool Failure During Machining Processes?Following industry standards for preparing milling cutter edges helps keep you safe while working. When cutters are made correctly, they are less likely to break. This means fewer accidents and less mess. It also makes your work easier and helps your machines last longer. So, taking the time to prepare tools right is very important!