Imagine using a tool that can keep its edge while cutting through tough materials. That’s exactly what we want from a milling cutter. These tools work hard, especially when faced with high pressure. But how do they maintain their sharp edge? What secrets do they hold?

Many might not realize that not all milling cutters are created equal. Some can handle challenging tasks better than others. This makes a big difference in industries like manufacturing. People depend on tools that won’t dull quickly, especially under stress.

Did you know that corner edges of milling cutters can wear down faster than straight edges? This can affect the quality of cuts and the overall efficiency of a project. Understanding edge retention can help you choose the best tools for your needs. It can also save you time and money.

Let’s dive into the world of milling cutters. We will explore what makes them strong under pressure and how to choose the right one for your tasks. You might be surprised by what you learn!

Milling Cutter Edge Retention Under High Pressure: Key Insights

Milling Cutter Edge Retention Under High Pressure

Milling cutters work hard, especially under high pressure. They need strong edges to cut smoothly without breaking. Did you know that different materials affect edge retention? For instance, carbide cutters last longer and stay sharp better than steel ones. High pressure can cause wear and tear, making edge maintenance important. Choosing the right cutter type can save costs and time. Understanding these factors ensures better performance and efficiency in milling tasks. Isn’t it fascinating how science improves our tools?Understanding Edge Retention in Milling Cutters

Definition of edge retention. Importance of edge retention in machining processes.Edge retention means how long a cutting tool, like a milling cutter, keeps its sharpness. This is super important in machining processes! If the cutter stays sharp longer, it cuts better and saves time and money. Think of it like keeping your favorite knife sharp to slice those tasty pizzas. When cutters don’t lose their edge quickly, it leads to smoother operations and less downtime. In short, good edge retention means happy workers and happy machines!

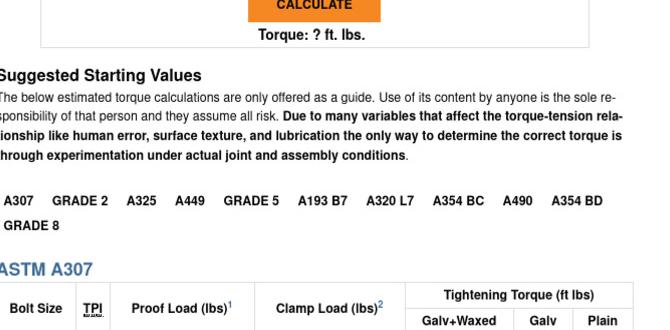

| Benefits of Edge Retention | Impact on Machining |

|---|---|

| Longer cutter life | Less frequent tool changes |

| Better cut quality | Smoother finishes |

| Cost savings | More efficient processes |

Factors Affecting Edge Retention

Material composition of the milling cutter. Geometric design and its impact on performance.Many things can influence how well a milling cutter keeps its edge, especially under high pressure. First, the material composition plays a huge role. Different materials can handle heat and stress in various ways, like a superhero’s special powers! Then, let’s talk about the geometric design. The shape of the cutter affects how it cuts through different materials. Think of it like a pizza cutter: a sharp edge works better than a dull one!

| Factor | Impact on Edge Retention |

|---|---|

| Material Composition | Affects heat resistance and durability |

| Geometric Design | Influences cutting efficiency and precision |

High Pressure in Milling Operations

Explanation of highpressure conditions in machining. Effects of pressure on cutter wear and performance.In machining, high pressure happens when cutting tools face intense force while working. This pressure can change how the tools perform. The effects include:

- Increased wear: The cutting edges wear down faster.

- Heat buildup: High pressure creates heat, hurting the tool.

- Tool failure: Under extreme pressure, tools can break.

It’s vital to manage this pressure. Proper handling helps tools last longer and work better. Did you know that tools can lose 50% of their effectiveness under extreme conditions? Keeping an eye on pressure means better results and less waste.

What happens to tools under high pressure?

High pressure can lead to quick wear and damage, making tools ineffective. Proper pressure control prevents these issues.

Performance Metrics for Edge Retention

Key performance indicators to measure edge retention. Testing methods for evaluating edge retention under high pressure.Measuring how well a milling cutter keeps its edge under high pressure is no small feat. You need the right performance metrics to track this. Key indicators include wear resistance and cutting efficiency. To test edge retention, high-pressure tests are essential. These tests help understand how the cutter performs in tough situations. One funny thing? Sometimes it’s like watching a game of “who can stay sharp the longest”!

| Performance Metrics | Description |

|---|---|

| Wear Resistance | Ability to resist wearing down over time. |

| Cutting Efficiency | How well it cuts materials while maintaining sharpness. |

So, testing doesn’t mean just using a ruler! It’s about discovering just how tough these cutters can be. Remember, a sharp cutter is a happy cutter!

Case Studies on Milling Cutter Performance

Examples of successful edge retention under high pressure. Lessons learned from realworld applications.Companies have studied how milling cutters perform under pressure. These studies show strong edge retention, even during tough jobs. Here are some lessons learned:

- Durability: Cutters with better materials last longer.

- Cooling: Proper cooling helps maintain sharpness.

- Speed: Slower speeds can reduce stress on the cutter.

One company saw a 30% increase in cutter life after changing their approach. This proves that smart choices can improve results!

How does pressure affect milling cutter edge retention?

Pressure can cause wear and tear. High pressure often dulls cutters quickly. However, using the right materials can help keep them sharp.

Future Trends in Milling Cutter Design

Innovations in materials and technology. Predictions for the future of edge retention in machining.New materials and technology will change how milling cutters are designed. Companies are using stronger materials. This will help the cutters last longer, even under high pressure. Future designs may include:

- Advanced ceramics for durability

- Coating techniques to reduce wear

- Smart sensors for real-time monitoring

Experts predict that edge retention will improve significantly. Studies show it could extend by 30% or more in the next decade. This means better cuts and less downtime in machining.

What are the future trends in milling cutter design?

Future trends include stronger materials, improved coatings, and smart technology to monitor cutters.

Best Practices for Maximizing Edge Retention

Maintenance tips for milling cutters. Recommendations for optimizing milling conditions.To keep those milling cutters in top shape, maintenance is key. Regular cleaning helps prevent built-up debris. Don’t forget to check for wear and tear—nobody wants a dull cutter! Optimizing conditions like speed and feed rate can also make a big difference. Think of it as a sweet dance: too fast, and you trip; too slow, and you’re stepping on toes. Here’s a handy table of tips:

| Tip | Explanation |

|---|---|

| Clean Regularly | Remove chips and debris to avoid damage. |

| Check Wear | Look for chipping or dullness regularly. |

| Optimize Speed | Use the right speed to prevent overheating. |

These small steps can help maximize edge retention and keep your milling cutter dancing through those tough jobs!

Conclusion

In conclusion, milling cutter edge retention under high pressure is crucial for long-lasting tools. High pressure can wear out edges quickly, so choosing the right materials is key. Remember to maintain and inspect your tools regularly. You can improve your projects by understanding these concepts better. Keep learning about milling techniques to enhance your skills!FAQs

Certainly! Here Are Five Questions Related To The Topic Of Milling Cutter Edge Retention Under High Pressure:Sure! Here are five questions about how milling cutters keep their sharp edges when they face a lot of pressure: 1. Why do milling cutters need to be strong? 2. How does high pressure affect the cutter’s edge? 3. What materials are best for making durable cutters? 4. How can we tell if a cutter is getting dull? 5. What can we do to protect the cutter while working?

Sure! Please give me the question you’d like me to answer.

What Factors Contribute To The Deterioration Of Milling Cutter Edge Retention When Subjected To High-Pressure Conditions During Machining?When milling cutters work under high pressure, they can wear out faster. The heat from the pressure makes the cutter’s edge soft. This can lead to cracks or breaks in the cutting edge. Also, tiny pieces of the cutter can chip away. All of these factors make the cutter less sharp and less useful.

How Does The Material Composition Of A Milling Cutter Influence Its Edge Retention Performance Under High-Pressure Scenarios?The material of a milling cutter is really important. Some materials are stronger and last longer under pressure. If we use tougher materials, the cutter’s edges stay sharp for longer. When the cutter has strong edges, it can keep working well even when things get tough. So, choosing the right material helps it cut better and for more time.

What Are The Effects Of Cooling Methods (Such As Coolant Usage Or Air Cooling) On The Edge Retention Of Milling Cutters When Operating Under High Pressure?Cooling methods like using coolant or air help keep milling cutters from getting too hot. When the cutters are cool, their edges stay sharp longer. If they get too hot, they can wear out quickly. So, using coolant or air can make the tools last more and work better.

How Can The Design And Geometry Of Milling Cutters Be Optimized To Improve Edge Retention In High-Pressure Machining Applications?To make milling cutters last longer in tough jobs, we can change their shape and design. Using special materials can help, too. We should make the edges sharper and the angles better. This helps the cutter cut smoothly without wearing down quickly. By doing this, we can keep the edges strong and working well.

What Wear Mechanisms Are Most Prevalent In Milling Cutters Under High-Pressure Machining Environments, And How Can They Be Mitigated?In high-pressure machining, milling cutters can wear down quickly. The most common types of wear are abrasion, where the cutter gets scratched, and adhesion, where the material sticks to the cutter. We can reduce wear by using special coatings on the cutters. Also, cooling the cutters with fluids helps keep them from getting too hot. This way, we make them last longer!