Have you ever wondered why some milling cutters work better than others? The secret often lies in the flute length selection. Choosing the right flute length can make a big difference in your projects.

Imagine trying to cut a thick piece of wood with a very short cutter. It wouldn’t go well, right? However, if you pick the right length, you can slice through materials easily.

Fun fact: Milling cutters can come in different flute lengths! Each is designed for specific tasks. This choice affects how well the cutter performs.

In this article, we will explore how to select the perfect milling cutter flute length. You will learn tips and tricks to make your milling tasks smoother. Let’s dive in and discover the world of milling cutters together!

Milling Cutter Flute Length Selection: Key Factors Explained

Milling Cutter Flute Length Selection

Choosing the right flute length for a milling cutter matters more than you might think. The flute length affects how well the cutter removes material. A shorter flute can improve strength, while a longer flute helps in chip removal. Did you know that choosing the wrong length can lead to poor performance? Consider the material you’re cutting and the depth needed. Making the right selection can save time and money in your projects, making milling easier and more efficient!Understanding Flute Length

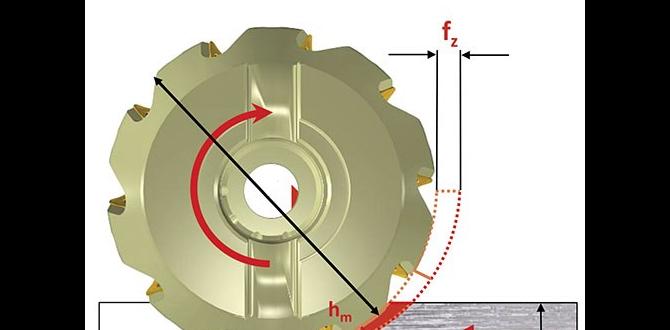

Definition of flute length in milling cutters. Importance of flute length in milling operations.Flute length is the distance from the tip of a milling cutter to where the flutes start. This length matters because it affects how well the cutter works. A longer flute can remove more chips, helping the tool stay cooler. It also leads to a smoother finish. On the other hand, a shorter flute can be stronger and better for tough materials. Choosing the right length can make your projects go smoother and faster!

Why is flute length important?

Flute length is important because it affects cutting speed and quality. A proper flute length helps in efficient chip removal and smoother cuts.

Key aspects of flute length:

- Longer flutes clear chips quickly.

- Shorter flutes are stronger for tougher materials.

- Right length enhances overall performance.

Factors Influencing Flute Length Selection

Material type and its impact on flute length. Depth of cut and its relationship to flute length.Choosing the right flute length for a milling cutter is important. The material type affects flute length choices. Harder materials need shorter flutes for strength. Softer materials allow longer flutes for better chip removal. Depth of cut plays a big role too. If you’re cutting deep, shorter flutes help prevent breakage. For shallow cuts, longer flutes can manage the movement easily.

How does material type affect flute length?

Different materials require different flute lengths to work best. Hard materials need shorter flutes for strength, while softer materials can use longer flutes for better performance.

What is the relationship between depth of cut and flute length?

If the cut is deep, shorter flutes are safer. For shallow cuts, longer flutes are more effective. This ensures better control during milling.

Types of Flute Designs

Standard flute designs and their applications. Variations in flute length and design (e.g., short vs. long).Milling cutters have different flute designs for different tasks. Standard designs like two-flute, four-flute, and six-flute work better with certain materials. For example, a two-flute cutter removes chips faster but isn’t great for fine finishes. Flute length matters too! Short flutes are sturdy and keep things steady, while long flutes help with deep cuts. Remember, using the right flute is like wearing the right shoes for a race—nobody wants a twisted ankle!

| Flute Type | Applications |

|---|---|

| Two-Flute | Best for soft materials; fast chip removal |

| Four-Flute | Great for harder materials; smoother finishes |

| Six-Flute | Effective in high-speed machining |

Performance Implications of Flute Length

Effects of flute length on chip removal and breakage. Correlation between flute length and cutting speed.The length of milling cutter flutes plays a big role in performance. Longer flutes help move chips away from cutting areas. Shorter flutes tend to break chips easily. This means that flute choice can affect how smoothly cutting happens.

Also, flute length impacts cutting speed. Longer flutes can slow down cuts, while shorter flutes allow faster speeds. Finding the right flute length can improve efficiency and reduce waste.

- Longer flutes: Better chip removal, less chance of breakage.

- Shorter flutes: Higher cutting speeds, but may lead to more chip breakage.

How does flute length affect milling?

Flute length influences chip removal and cutting speed. Longer flutes are great for clearing chips, but shorter ones cut faster.

Recommended Flute Lengths for Different Applications

Optimal flute lengths for various materials (metal, wood, plastics). Specific recommendations based on machining operations.Selecting the right flute length for milling cutters can greatly affect your work. Here are some tips for different materials:

- Metal: A flute length of 3 to 4 times the diameter works well for tough metals.

- Wood: Use shorter flutes, about 2 to 3 times the diameter for clean cuts.

- Plastics: A length of 2 times the diameter helps prevent melting.

Choosing the right flute length helps get the best results from your machining operations. Always consider the material before starting.

What are the best flute lengths for different machining tasks?

For drilling holes, shorter flutes are better. For shaping and contouring, longer flutes provide a smoother finish.

Common Mistakes in Flute Length Selection

Mistakes to avoid when selecting flute lengths. Consequences of improper flute length on machining performance.Selecting the wrong flute length can lead to big problems. Common errors include choosing too long or too short flutes. If flutes are too long, they can flex, causing poor cuts. On the flip side, short flutes may not remove enough material. The result? Inefficiency and frustration!

Here’s a table summarizing some mistakes:

| Mistake | Consequence |

|---|---|

| Choosing Flutes Too Long | Flexing and poor cuts |

| Choosing Flutes Too Short | Insufficient material removal |

| Ignoring Material Type | Poor performance and wear |

Remember, the right flute length can save you time and keep your machine happy. As they say, “It’s better to measure twice than to cut once… or in this case, to flute!”

Adjusting Flute Length for Enhanced Machining

Techniques for modifying existing milling cutters. When to consider custom flute length options.Choosing the right flute length can make a big difference in machining. Shorter flutes can help with precision, while longer ones can remove more material. If you have existing milling cutters, you can adjust them with techniques like grinding or re-tip options. Custom flute lengths are also available, especially when standard options just won’t cut it—or when your cutter feels like a weird giraffe at a short-stature convention!

| Flute Length | Best For |

|---|---|

| Short | Fine details and precision cuts. |

| Medium | Versatile use in various materials. |

| Long | Heavy material removal and deep cuts. |

Keep in mind, customizing flute length usually pays off if you’re working on tough projects. It’s like getting a haircut; sometimes, a trim is all you need to look sharp and get the job done!

Industry Trends and Innovations in Flute Length Design

Latest advancements in milling cutter technology. Future trends impacting flute length and design selection.New technology changes how we make milling cutters. Flute design is better than ever. Recent advancements focus on longer, more precise flutes for smoother cuts. This leads to faster production and better surfaces. Future trends may include:

- Smart materials that adapt to the job.

- 3D printing for custom flute designs.

- Eco-friendly options with less waste.

These updates help manufacturers stay ahead and adjust flute length based on new needs. Innovations continue to reshape milling cutter design for future success.

What are the latest advancements in milling cutter technology?

The latest advancements include improved flute lengths for enhanced cutting efficiency and smart materials that respond to different machining tasks.

Conclusion

In conclusion, selecting the right milling cutter flute length is crucial for your projects. Shorter flutes provide faster cuts, while longer flutes improve material removal. Consider your material and the desired finish when choosing. Remember to practice and experiment with different lengths to find what works best for you. For more tips, check out our other articles on milling tools!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Flute Length Selection:Sure! Here are some questions about choosing how long the flutes on a milling cutter should be: 1. Why is flute length important? It helps the cutter remove material quickly. If it’s too short, it won’t do its job well. 2. How do you know the right flute length? You should consider the material you’re cutting. Softer materials can use shorter flutes, while harder ones need longer ones. 3. What happens with a flute that’s too long? It can bend or break easily. Shorter flutes are stronger and safer for many cuts. 4. Can you change the flute length yourself? No, you usually need to buy a different cutter to get the right length. 5. How do I pick the right cutter? Check the material type and the thickness of what you’re working on. That will help you choose wisely!

Sure! Please provide the question you’d like me to answer.

What Factors Should Be Considered When Determining The Optimal Flute Length For A Milling Cutter?When choosing the best flute length for a milling cutter, you should think about how deep you want to cut. A longer flute can reach deeper but can be weak. The material you are cutting also matters; hard materials need strong cutters. Finally, consider the speed of the machine and how quickly you need to work. This will help you pick the right length!

How Does Flute Length Affect The Chip Removal Efficiency During The Milling Process?Flute length is how long the grooves are on the end of the tool we use to cut metal. When the flutes are longer, they can carry away more tiny pieces, called chips. This helps the tool cut better and stay cool. If the flutes are too short, the chips can get stuck, making it harder to cut. So, longer flutes usually mean better chip removal.

In What Situations Would A Longer Flute Length Be Beneficial Compared To A Shorter Flute Length In Milling Applications?A longer flute length can help when you need to cut deeper into a material. It lets you reach tough spots that a shorter flute can’t touch. If you’re working on thick materials, longer flutes are better. They also help remove chips more easily, making your work smoother. So, a longer flute can be useful for deeper and harder jobs!

How Does The Material Being Machined Influence The Choice Of Flute Length For Milling Cutters?The material we are cutting affects the flute length we choose for milling cutters. Softer materials, like wood, might need shorter flutes because they cut easily. Harder materials, like metal, usually need longer flutes to help remove the material better. The right flute length helps us make clean and smooth cuts. So, we always think about the material when picking flute lengths!

What Are The Potential Consequences Of Selecting An Inappropriate Flute Length For A Specific Milling Operation?If you choose the wrong flute length for milling, it can cause problems. The tool might break easily, which is dangerous. It can also make a mess and create rough surfaces. You might have to fix mistakes, wasting time and materials. Overall, using the right flute length helps everything go smoothly.