Have you ever wondered how airplanes and race cars are made lighter and faster? The secret often lies in amazing materials like CFRP, or carbon fiber reinforced plastics. These materials are super strong and very light. But working with CFRP can be tricky. That’s where a special tool called a milling cutter comes in.

Milling cutters are designed to cut these unique materials safely and effectively. But why are they so important? Imagine trying to use regular tools on something as tough as CFRP. It wouldn’t end well!

Here’s a fun fact: using the right milling cutter can make the difference between a smooth finish and a lot of frustration. Knowing how to choose the best milling cutter for CFRP materials can help you create amazing things. So, let’s dive into the world of milling cutters and uncover more about their role in shaping the future of engineering!

Milling Cutter For Cfrp Materials: Choosing The Right Tool

Milling Cutter for CFRP Materials

Using a milling cutter for CFRP materials requires special attention. CFRP, or carbon fiber reinforced polymer, is strong but tricky to cut. The right milling cutter can make the job easier and cleaner. Did you know that dull cutters can cause damage? They can also lead to poor finishes. Choosing the right speed and feed rate is essential. This ensures you get the best results when working with these materials. Proper tools make all the difference!Understanding CFRP Materials

Definition and characteristics of CFRP (Carbon Fiber Reinforced Polymer). Applications and significance in various industries.Carbon Fiber Reinforced Polymer (CFRP) is like a superhero of materials! It combines carbon fibers with a polymer resin. This makes it super strong yet surprisingly light. You can find CFRP in many places, from airplanes to sports cars. In fact, its use can reduce weight by up to 50% compared to other materials, like metals. So, if you ever find yourself flying through the sky in a sleek jet, thank CFRP for keeping it light and zippy!

| Characteristic | Benefit |

|---|---|

| Lightweight | Improves fuel efficiency |

| High strength | Increases durability |

| Corrosion-resistant | Longevity in harsh conditions |

Types of Milling Cutters Suitable for CFRP

Carbide vs. HSS milling cutters. Specialized milling cutter designs for CFRP (e.g., diamondcoated, polycrystalline).There are different types of milling cutters for CFRP materials. You can choose between carbide and HSS cutters. Carbide cutters are strong and last longer, while HSS cutters are cheaper but wear out faster. For CFRP, specialized designs work best.

- Diamond-coated cutters are excellent for durability. They cut cleanly and are very sharp.

- Polycrystalline cutters also perform well on CFRP. They offer better heat resistance and precision.

What types of milling cutters are best for CFRP materials?

Carbide and specialized cutters like diamond-coated and polycrystalline are best for CFRP materials. They cut smoothly and last longer, making them ideal for this hard material.

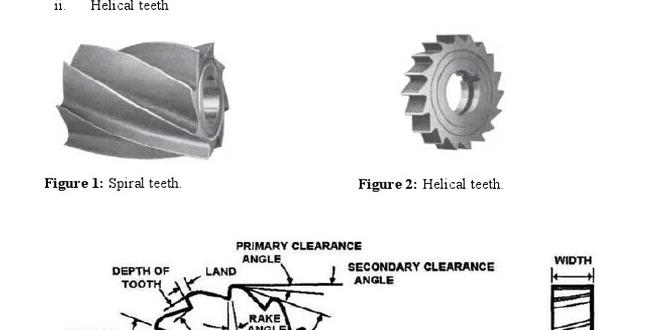

Key Features to Look for in a Milling Cutter for CFRP

Cutting edge geometry and its importance. Tool coating options and their benefits.Choosing the right milling cutter is important for cutting CFRP materials. The cutting edge geometry affects how well the cutter performs. A sharp shape helps in making clean cuts and reduces damage to the material. Tool coating options also matter. Different coatings can make the cutter last longer and resist heat. Here are some features to consider:

- Sharpness: Helps in quick and clean cuts.

- Shape: Angular edges cut better through tough materials.

- Coatings: Options like TiN or TiALN improve durability.

What is cutting edge geometry?

Cutting edge geometry refers to the shape of the cutter’s edge. It must be sharp for smooth cutting.

Why are tool coatings important?

Tool coatings protect the cutter from heat and wear. They help keep the cutter sharp for longer, making work easier.

Milling Techniques and Best Practices for CFRP Machining

Recommended cutting speeds and feeds. Cooling methods and their effect on tool life.Successful machining of CFRP materials requires proper milling techniques. First, choose cutting speeds between 80 to 120 meters per minute. Adjust the feed rates based on your tool diameter, typically ranging from 0.1 to 0.5 mm per tooth. Now, let’s get to cooling! Using coolant can be a game-changer, extending tool life by up to 50% while reducing dust clouds, which can look like a bad science experiment gone wrong!

| Parameter | Recommendations |

|---|---|

| Cutting Speed | 80-120 m/min |

| Feed Rate | 0.1-0.5 mm/tooth |

Remember, a cool cutter is a happy cutter!

Common Problems and Solutions in CFRP Milling

Delamination and surface quality issues. Tool wear and selection of appropriate feed rates.Milling CFRP materials can feel like trying to slice a tough sandwich. Two big challenges are delamination and keeping a smooth surface. Delamination is when layers separate, and it’s no fun! The tools can wear out quickly, which can mess up your work. To fix these problems, pick the right tool for the job and adjust your feed rates like a chef seasoning a dish. Below is a handy table for quick tips!

| Problem | Solution |

|---|---|

| Delamination | Select sharp tooling and use optimized speeds. |

| Poor Surface Quality | Use proper feed rates and cooling techniques. |

| Tool Wear | Choose high-quality cutters for CFRP. |

Case Studies: Successful CFRP Milling Projects

Examples of industries that benefited from optimized milling. Lessons learned from realworld applications.Many industries have seen huge wins from using the right milling cutters for CFRP materials. For example, the aerospace sector improved aircraft parts’ lifespans by 30% just by optimizing their milling processes. A few car manufacturers also learned that smarter milling means lighter cars, boosting performance. Less weight often means better speed! “If you can’t race it, you can’t chase it!” These real-world applications teach us that choosing the right tools can lead to success.

| Industry | Benefit |

|---|---|

| Aerospace | 30% longer lifespan for parts |

| Automotive | Improved performance with lighter materials |

Future Trends in Milling Cutters for CFRP Materials

Innovations in milling cutter technology. Predictions for the future of CFRP machining techniques.Milling cutter technology is changing at lightning speed! New tools are smarter, sharper, and ready to tackle CFRP materials like pros. In the future, we may see *super-materials* that are lighter and tougher, making cutting even easier. Expect innovations like smart sensors that help avoid mistakes while machining. Plus, with green technology on the rise, eco-friendly milling cutters are around the corner. Imagine a tool so sharp, it could cut through boredom too!

| Emerging Innovations | Future Predictions |

|---|---|

| Smart technology | Eco-friendly materials |

| Advanced coatings | Improved efficiency |

| Telematics integration | Automation in machining |

Conclusion

In conclusion, using the right milling cutter for CFRP materials is crucial for smooth, accurate cuts. You should consider factors like tool type, coatings, and speeds. This knowledge helps you choose the best cutter for your projects. We encourage you to research and explore different milling options to enhance your work with CFRP materials. Happy milling!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutters For Cfrp (Carbon Fiber Reinforced Polymer) Materials:Sure! Milling cutters for CFRP help us cut carbon fiber materials easily. They are like special tools that make clean and smooth edges. These cutters need to be very strong to handle the tough fibers. When using them, we have to be careful to avoid breaking the tool. It’s important to choose the right cutter for the job!

Sure! Please provide the question you want me to answer.

What Are The Key Design Features Of Milling Cutters That Make Them Effective For Machining Cfrp Materials?Milling cutters for CFRP, or carbon fiber reinforced plastic, have special features. They often have sharp edges to slice through the tough material. Their shape helps to remove small pieces easily, which keeps the cutting smooth. Many cutters are made from strong materials to stay sharp longer. These designs help us machine CFRP without damaging it.

How Do Different Cutting Materials (Such As Carbide Or Diamond-Coated) Influence The Performance And Tool Life Of Milling Cutters When Processing Cfrp?Different cutting materials help tools cut better and last longer. Carbide tools are strong and work well with CFRP, which stands for carbon fiber-reinforced polymer. Diamond-coated tools are even tougher and stay sharp longer. This means they can cut more pieces before getting dull. So, choosing the right material helps us do our job faster and easier!

What Are The Common Challenges Faced When Milling Cfrp Materials, And How Can They Be Mitigated Through Tool Selection And Machining Parameters?When we mill CFRP, which stands for Carbon Fiber Reinforced Polymer, we face some challenges. The material can splinter and get too hot, leading to rough edges. We can choose special tools made for hard materials to cut better. We also need to adjust the speed and pressure while machining to keep it cool and smooth. This way, we can make better cuts and avoid problems!

In Terms Of Surface Finish And Dimensional Accuracy, How Does The Choice Of Milling Cutter Geometry Affect The Outcome When Working With Cfrp?The shape of the milling cutter can change how well we cut Carbon Fiber Reinforced Plastic (CFRP). A good cutter makes smooth surfaces, while a bad one can leave rough spots. It also helps keep the size of the cut part just right. So, choosing the right cutter is very important for a nice finish and accuracy.

What Advancements In Milling Cutter Technology Have Been Made Recently To Enhance The Efficiency And Precision Of Cfrp Machining?Recently, milling cutters have improved a lot to help us cut carbon fiber reinforced plastic (CFRP) better. These new cutters have sharper edges, which makes them cut smoother and faster. They also use special coatings that help them last longer and reduce wear. With these changes, we can create cleaner shapes and save time when making things from CFRP. It’s exciting to see how tools can get better and help us work more efficiently!