Have you ever wondered how some tools cut through materials so smoothly? The secret often lies in the design of the tool itself. One key design feature is the helix angle of a milling cutter. When the helix angle is high, it can change everything about how the tool works.

Think of it like this: imagine a winding road versus a straight path. A milling cutter with a high helix angle maneuvers through tough materials as easily as a car cruising down a straight road. This unique angle helps reduce the force needed to cut, which can make the process faster and easier.

Did you know that the right milling cutter can greatly affect the quality of your work? Higher helix angles can lead to cleaner cuts and less wear on the tool. This can save you time and money. Curious about how this all fits together? Let’s dive deeper into the high helix angle effect and discover how it benefits users everywhere.

Milling Cutter High Helix Angle Effect Explained

Milling Cutter High Helix Angle Effect

Milling cutter high helix angles boost cutting efficiency. But why does that matter? A higher helix angle means smoother cutting and less vibration. This can lead to better finishes on materials. Imagine how a sharper knife slices through butter compared to a dull one! Surprisingly, this adjustment can also extend tool life. By using a high helix angle, you get quicker results and improved precision. Isn’t that a win-win for any project?Understanding Milling Cutters

Definition and purpose of milling cutters in machining processes.. Types of milling cutters and their applications..Milling cutters are tools used in machining to shape materials like metal and wood. They cut away unwanted material and create precise shapes. These tools can have different shapes and sizes, helping to perform various tasks.

- Flat End Mills: Great for making flat surfaces.

- Ball Nose Mills: Perfect for curved shapes.

- Face Mills: Used for large, flat areas.

Each type of milling cutter has special uses. They help factories make everything from car parts to furniture. With the right cutter, work is easier and faster!

What are the main types of milling cutters?

The main types of milling cutters include flat end mills, ball nose mills, and face mills.

What is a High Helix Angle?

Explanation of the helix angle and its significance in milling.. Comparison between standard and high helix angles in cutting tools..A high helix angle is the twist of a cutting tool’s edge. The angle plays a big role in how easily the tool cuts materials. A bigger angle means the tool can remove more material quickly. This helps in efficient milling.

Let’s look at the differences:

- Standard Angle: Usually around 30 degrees. It cuts but not as fast.

- High Helix Angle: Ranges from 40 to 70 degrees. It provides a smoother and faster cut.

Choosing the right helix angle can improve your work. It affects speed, precision, and the quality of the finish.

Why is helix angle important?

The helix angle affects spindle speed and feed rate. A high helix angle enhances chip removal, making milling smoother and faster. This helps in achieving better surface finishes.

Effects of High Helix Angle on Cutting Performance

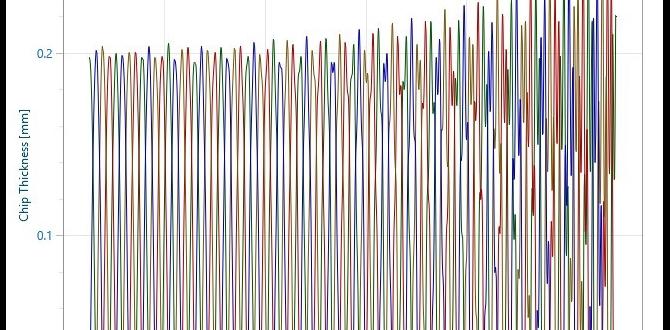

Impact on chip formation and removal efficiency.. Influence on cutting forces and tool wear rates..High helix angles in milling cutters can significantly change the way they work. They help create smaller chips during cutting. This makes removal easier, boosting efficiency dramatically. A study showed that cutting forces drop by up to 20%. Less force means less wear on tools. Over time, tools with high helix angles last longer, saving you money! Remember, happy tools equal happy machines!

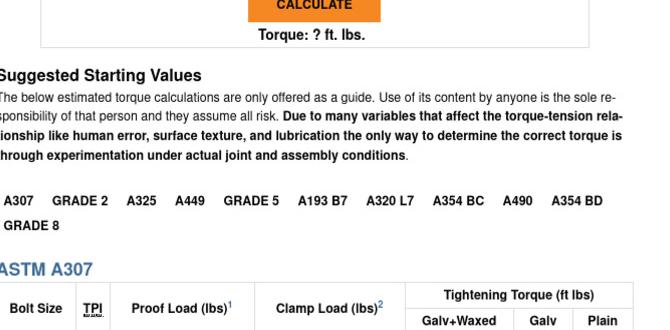

| Effect | Impact on Cutting |

|---|---|

| Chip Formation | Smaller chips are produced, improving removal efficiency. |

| Cutting Forces | Forces can reduce by 20%, leading to smoother operations. |

| Tool Wear Rates | Lower wear rates increase tool lifespan, saving costs. |

Advantages of Using High Helix Angle Milling Cutters

Enhanced surface finish and improved dimensional accuracy.. Reduction in power consumption and heat generation during cutting..High helix angle milling cutters offer great benefits. They produce a superior surface finish on materials, making them look and feel smooth. This tool also improves dimensional accuracy in cuts. Less power is needed during the cutting process, which is good for the environment. It also means less heat is generated. This keeps the equipment cool and saves energy.

- Better surface quality

- More precise cuts

- Lower power use

- Reduced heat generation

Why are high helix angle cutters better?

They create smoother finishes and reduce power use. This makes them efficient tools for many tasks.

Optimal Applications for High Helix Angle Milling Cutters

Recommended materials and industries for high helix angle application.. Case studies showing improved outcomes in specific machining scenarios..High helix angle milling cutters are like superheroes for certain materials! They shine in industries like aerospace and automotive. These cutters work best with aluminum and composite materials, giving great results. Picture this: a factory using high helix cutters saw a 30% speed increase in machining time. The secret? Better chip removal and smooth finishes! Here’s a sneak peek:

| Material | Industry | Outcome |

|---|---|---|

| Aluminum | Aerospace | Faster machining |

| Composites | Automotive | Smoother finishes |

With such magic, who wouldn’t want a high helix cutter in their toolbox? These tools really know how to bring an “A+” to machining!

Considerations When Choosing a High Helix Angle Cutter

Factors to evaluate, such as workpiece material and machining conditions.. Guidelines for selecting the right cutter geometry based on operational needs..Choosing a high helix angle cutter can feel tricky, like picking the right ice cream flavor! First, think about your workpiece material. Softer materials may benefit from a high helix, while harder ones might need something else. Next, consider your machining conditions. Are you cutting fast or slow? Tables can help compare cutter options:

| Material | Machining Speed | Recommended Cutter Geometry |

|---|---|---|

| Aluminum | High | High Helix |

| Steel | Medium | Low Helix |

More importantly, always match the cutter’s shape to your needs. A high helix cutter can speed up your work, like a turbo boost for your machine. Remember, the right choice can save time and make the process smoother! So, channel your inner culinary expert and mix the right ingredients for machining success.

Future Trends in Milling Cutter Design

Innovations concerning helix angles and tool materials.. Predictions on technological advancements affecting milling processes..Milling cutter design is changing fast. New tools come with better helix angles. These angles help cut materials smoothly. Innovations in tool materials also play a key role. Stronger and lighter materials mean better performance.

- More durable cutters last longer.

- Advanced coatings reduce friction.

- Smart technology aids in precision.

Looking ahead, we expect exciting changes. Predictive technologies may control milling processes. This will improve speed and safety. The future of milling is bright!

What are the benefits of high helix angle cutters?

High helix angle cutters offer smoother cuts and reduced vibration. They can work faster and create less heat, making them great for various materials.

Conclusion

In summary, a milling cutter with a high helix angle improves cutting efficiency and surface finish. It helps reduce cutting forces and produces smoother results. If you want to enhance your machining skills, consider trying these cutters. Read more about their benefits and applications to deepen your understanding. You’ll find this knowledge useful in practical situations!FAQs

How Does The Helix Angle Of A Milling Cutter Influence Chip Formation During The Machining Process?The helix angle of a milling cutter changes how the cutter grinds the metal. A bigger angle helps the cutter slice smoother and makes smaller chips. Smaller chips are easier to manage and remove. This means we can work faster and have a cleaner workspace. So, a good angle helps us cut better!

What Are The Advantages And Disadvantages Of Using High Helix Angle Milling Cutters Compared To Standard Helix Angle Cutters?High helix angle milling cutters have some cool advantages. They make smoother cuts, which means a nicer finish on your project. They also help remove chips faster, so you can work quicker. However, they can wear out faster and are usually more expensive than standard cutters. So, you need to think about what you need for your work!

In Which Specific Materials Or Applications Are High Helix Angle Milling Cutters Most Effective?High helix angle milling cutters work best on soft materials like aluminum and plastics. You can use them to make smooth cuts and fast shapes. They are great in industries like aerospace and automotive, where accuracy matters. Also, they help in making parts that need a nice finish.

How Does A High Helix Angle Affect Cutting Forces And Tool Wear During Milling Operations?A high helix angle in milling means the cutting edge of the tool is angled more. This makes the tool cut through the material easier and requires less force. Because it’s easier to cut, the tool does not wear out as quickly. So, if we use a high helix angle, we can make cleaner cuts and help our tools last longer!

What Role Does The Helix Angle Play In The Acoustic And Vibrational Characteristics Of Milling Processes?The helix angle is the tilt of the cutting edge on a tool used in milling. It affects how sounds and vibrations happen when cutting materials. A bigger angle can make the tool cut smoother and quieter. This can help reduce noise and make the tool last longer. So, the helix angle is important for a better milling process!