Imagine you’re in a workshop, surrounded by tools. You see machines whirring and sparks flying. This is where the magic of milling cutter insert indexing techniques happens. Have you ever wondered how these tiny, but powerful, tools can change the way we shape metal? Each insert is designed to fit perfectly and can be flipped or rotated. This helps keep the work going without stopping to change the whole cutter.

Using the right indexing technique can make a big difference. It can save time and money, while improving the final product too. Did you know that some shops can boost their efficiency just by learning these techniques? In this article, we will explore the best milling cutter insert indexing techniques. Get ready to uncover tips that can make your work easier and faster!

Milling Cutter Insert Indexing Techniques: A Comprehensive Guide

Milling Cutter Insert Indexing Techniques

Milling cutter insert indexing techniques can make your machining projects easier and more efficient. By properly indexing your inserts, you extend their life and ensure better cutting performance. Did you know that most cutting inserts can be rotated to use four different edges? This can save time and money while boosting productivity. Understanding these techniques helps you work smarter, not harder. Explore these valuable tips to transform your milling process!Understanding Milling Cutter Inserts

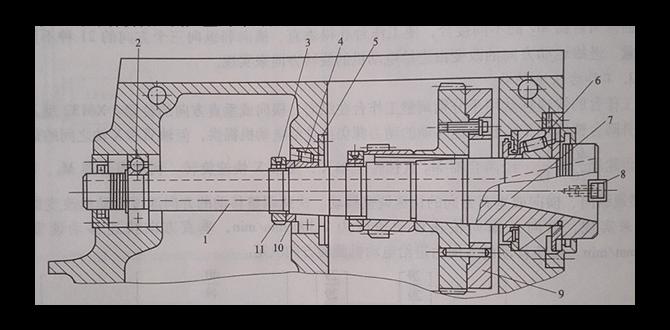

Definition and purpose of milling cutter inserts. Types of materials used in milling cutter inserts.Milling cutter inserts are special cutting tools used in milling machines. They help shape and cut materials with precision, making tasks easier and faster. Think of them as the tiny superheroes of the cutting world! There are different types of materials for inserts, like carbide and ceramic, each suited for specific jobs. Some are tough and can handle high speeds, while others are great for softer materials. Here’s a quick look at what these materials are:

| Material Type | Characteristics |

|---|---|

| Carbide | Strong, durable, and perfect for high-speed jobs. |

| Ceramic | Hard and heat-resistant, ideal for tough materials. |

| High-speed steel | Less expensive and used for softer materials. |

Understanding these inserts helps you pick the right one for your work.Just like choosing the right tool in a toolbox, it makes a big difference!

Importance of Indexing in Milling

Explanation of indexing and its role in milling operations. Benefits of proper indexing techniques for tool longevity and performance.Indexing is the process of adjusting tools during milling operations. This helps keep tools sharp and efficient. Proper indexing techniques are important for several reasons. They can enhance tool lifespan and ensure better performance. Here are some key benefits:

- Improves cutting efficiency

- Reduces wear and tear

- Enhances accuracy of cuts

- Minimizes downtime for replacements

Using effective indexing techniques can save money and time. Overall, indexing plays a crucial role in maintaining tools and achieving great results in milling.

What is indexing in milling?

Indexing in milling is adjusting the position of a tool to keep it effective. This helps provide better angles for cutting materials during the milling process.

Factors Influencing the Choice of Indexing Technique

Material characteristics and machining conditions. Tool geometry and design considerations.Choosing the right indexing technique can feel like picking the perfect pizza topping. It all comes down to material characteristics and machining conditions. For instance, hard materials need tougher tools. Meanwhile, soft materials can be played with using lighter tools. The tool’s shape also matters a lot. Broad or narrow, each design has its strengths. Be sure to consider these factors to keep your machining smooth and efficient!

| Factor | Consideration |

|---|---|

| Material Characteristics | Hard vs. Soft |

| Machining Conditions | Speed, Temperature |

| Tool Geometry | Design, Size |

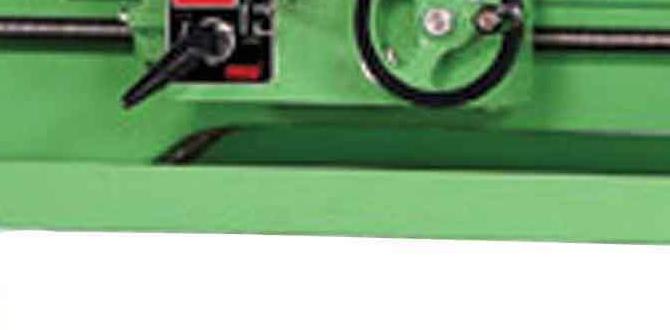

Step-by-Step Guide to Effective Indexing

Preparation and setup for indexing. Detailed procedure for common indexing techniques.Before diving into indexing, it’s like preparing your toolbox. Start with the right tools and a clean workspace. Measure your milling cutter inserts carefully. Keep them organized, so they’re not playing hide and seek! Next, when you’re ready to index, follow the steps below for some common techniques:

| Step | Action |

|---|---|

| 1 | Choose the right insert based on your material. |

| 2 | Align the cutter in the machine. |

| 3 | Secure it snugly! No wobbles allowed. |

| 4 | Run a trial cut to check accuracy. |

Follow these steps, and you’ll be a pro in no time! Remember, proper setup makes indexing smooth and easy. Happy milling!

Case Studies: Successful Indexing Techniques in Industry

Realworld examples of effective indexing implementations. Analysis of performance improvements and cost savings from using specific techniques.In the world of manufacturing, effective indexing techniques can make a huge difference. For instance, a factory recently switched to a new indexing method for their milling cutter inserts. This change boosted productivity by 30% and saved them thousands of dollars! Another company found that their tool life increased by 50% using a specific indexing technique. These real-world examples show how smart indexing can lead to great gains. Just remember, every well-indexed cutter is like a well-oiled machine—happy and efficient!

| Company | Improvement | Cost Savings |

|---|---|---|

| Tech Tools Inc. | 30% Productivity Boost | $15,000/year |

| Fast Cuts Ltd. | 50% Longer Tool Life | $8,000/year |

Future Trends in Milling Cutter Insert Indexing

Emerging technologies and innovations in indexing. Predictions for the future of milling cutter insert performance and efficiency.New technologies are shaking up the world of milling cutter insert indexing. Imagine machines that can think for themselves! Soon, **smart indexing systems** might predict tool wear and suggest changes before you even notice. The future looks bright for performance and efficiency in this field. Experts believe technology will boost productivity by up to 30%. With faster, more accurate tools, we’ll not only save time but maybe also find a way to add more snack breaks! So, let’s gear up for a fun, cutting-edge ride!

| Trend | Description | Impact |

|---|---|---|

| AI Integration | Machines learn from past data | Improved precision and fewer errors |

| Material Innovations | Stronger, lighter materials | Less wear and tear on tools |

| Automated Indexing | Self-adjusting inserts | More efficient setup times |

Conclusion

In conclusion, milling cutter insert indexing techniques help improve efficiency and reduce waste. By using these techniques, you can extend tool life and save time. Remember to try different methods to see which works best for you. Explore more resources or ask fellow machinists for tips to deepen your understanding and improve your skills further! Happy milling!FAQs

Certainly! Here Are Five Questions Related To Milling Cutter Insert Indexing Techniques:Sure! Here are five questions you might ask about milling cutter insert indexing techniques: 1. What is a milling cutter insert? 2. Why do we need to index the cutter inserts? 3. How do we change the inserts on a milling cutter? 4. When should we index an insert? 5. What tools do we need for indexing? These questions help us understand how to work with milling cutters better!

Sure! I’m ready to help you with your question. Just go ahead and ask!

What Are The Primary Benefits Of Using Indexed Milling Cutter Inserts Compared To Traditional Solid Tools In Machining Operations?Using indexed milling cutter inserts has some great benefits. First, they last longer than solid tools, so you don’t have to change them often. Second, you can easily replace just the insert when it gets dull. This saves you money and time. Finally, they are lighter and easier to handle, making your work smoother.

How Do Different Indexing Techniques Affect The Overall Efficiency And Lifespan Of Milling Cutter Inserts?Different indexing techniques change how we use milling cutter inserts. When we index, we flip or turn the insert to use a fresh edge. This helps the insert last longer because it doesn’t wear out in one spot. By using each side carefully, you can improve cutting speed and make better shapes. So, good indexing makes our tools work better and last longer!

What Factors Should Be Considered When Selecting The Appropriate Indexing Method For A Specific Machining Application?When choosing the right indexing method for machining, think about a few things. First, you should look at the type of piece you are making. Next, consider how fast you need to work. You also want to check how accurate the cuts need to be. Finally, think about how much money you can spend on the tools.

Can You Explain The Process Of Changing And Indexing Milling Cutter Inserts On A Machine Tool? What Best Practices Should Be Followed?To change milling cutter inserts, you first turn off the machine. Then, you use a special tool to unscrew the old insert. Next, place the new insert in the right spot and tighten it. Indexing means adjusting the insert so it cuts correctly. Always wear safety gear, keep your work area clean, and check your tools regularly!

How Has Advancements In Material Science And Technology Influenced The Design And Functionality Of Milling Cutter Inserts For Indexing?Advancements in material science and technology have made milling cutter inserts stronger and last longer. They use new materials that can handle heat better, so they don’t wear out quickly. This means we can cut through tougher materials easily. Because of these improvements, we can make better and more precise shapes in our work. This helps us save time and money, making our jobs easier!