Milling Cutter Iso Geometry Naming Structure Explained

Milling Cutter ISO Geometry Naming Structure

Understanding the milling cutter ISO geometry naming structure helps machinists choose the right tools. The ISO system uses specific codes to describe cutter features like diameter, type, and number of flutes. Imagine trying to find the perfect key for a lock; each detail matters! For instance, a single-digit code could indicate the cutter’s shape. Learning these codes can save time and ensure better results in machining projects. Knowing this structure can make all the difference in your work.Understanding ISO Geometry

Definition of ISO geometry in manufacturing.. Importance of ISO standards in milling cutter design..ISO geometry is a system used in manufacturing. It helps define the shapes and sizes of tools like milling cutters. This organization creates clear guidelines that make it easy for manufacturers to design tools. Following ISO standards in milling cutter design ensures everyone uses the same measurements and specifications. This consistency leads to better quality products and boosts productivity. Knowing these guidelines makes it easier to understand how tools work together in production.

What is the importance of ISO standards in milling cutter design?

ISO standards ensure safety, quality, and compatibility in milling cutter design.Key benefits include:

- Improved tool efficiency

- Enhanced safety in manufacturing

- Better communication between companies

Components of ISO Geometry Naming Structure

Breakdown of the naming structure components.. Explanation of each component’s significance..The ISO geometry naming structure has different parts. Each part helps us understand the tool better. Here are the main components:

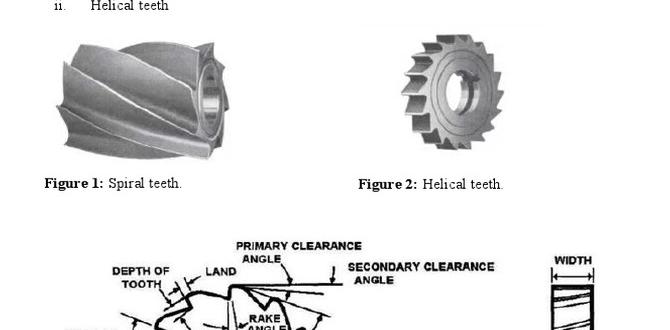

- Shape: Refers to the contour of the milling cutter.

- Diameter: Indicates the width of the cutter.

- Flutes: Tells how many spiral grooves are on the cutter.

- Coating: Shows what material is used to protect the cutter.

- Length: Signifies the total size of the tool.

Each part is important. For example, the shape affects how the tool cuts. The flutes help remove material smoothly. Knowing these details makes it easier to pick the right cutter for your work.

Why is knowing the naming structure important?

It helps users choose the right cutter for their tasks, ensuring better performance and efficiency.

Reading ISO Geometry Names

Stepbystep guide on how to interpret ISO geometry names.. Common abbreviations and symbols used in ISO naming..Understanding ISO geometry names can be fun and helpful! Here’s how to break it down step by step:

- Look for the letters. They tell you about the cutter type. For example, “T” means a tool cutter.

- Check the numbers. They show dimensions like diameter and angles.

- Symbols often appear too. These give more details, like whether a cutter has a specific shape.

Common abbreviations include:

- Ø: Means diameter.

- R: Stands for radius.

- P: Indicates pitch.

With practice, reading these names will become easy!

Common Questions

What do the letters mean in ISO names?

The letters give important clues about the tool type. For example, T indicates a tool cutter, and S may represent a shaft. Understanding these can help you choose the right cutter!

Applications of Milling Cutters with ISO Geometry

Industries utilizing ISO geometric standards.. Case studies on the effectiveness of standardized naming in practice..Milling cutters with ISO geometry standards are everywhere! They are widely used in industries like automotive, aerospace, and even furniture making. By using these standards, manufacturers ensure that their tools fit perfectly, making work smoother. Imagine trying to fit a square peg in a round hole—frustrating, right? Standardized naming helps avoid these mishaps. A case study showed that an automobile company reduced production time by 20% just by following ISO naming conventions!

| Industry | Effectiveness |

|---|---|

| Automotive | 20% faster production |

| Aerospace | Improved accuracy |

| Furniture | Less waste |

This shows that embracing ISO geometry is not just smart; it’s also a little bit like having a secret superhero on your team!

Benefits of Using ISO Geometry in Milling

Enhanced precision and consistency in manufacturing.. Streamlining communication between engineers and machinists..Using ISO geometry in milling is like having your cake and eating it too! It boosts precision and keeps things consistent in manufacturing. Engineers and machinists can talk the same language, which reduces confusion and mistakes. Say goodbye to the ‘lost in translation’ moments! Plus, a good reference system solves many headaches. It’s teamwork at its best—everyone wins!

| Benefit | Description |

|---|---|

| Enhanced Precision | More accurate cuts lead to higher quality products. |

| Streamlined Communication | Clear standards mean less mix-up between teams. |

Challenges in Implementing ISO Geometry

Common hurdles faced by manufacturers.. Solutions and best practices for overcoming these challenges..Manufacturers face many problems when using the milling cutter ISO geometry naming structure. Common issues include:

- Difficulty in understanding complex designs.

- Lack of standardization in naming conventions.

- Problems with training staff on new systems.

To overcome these challenges, businesses can:

- Simplify naming rules for easier learning.

- Provide hands-on workshops and training.

- Encourage teamwork to share knowledge.

Addressing these hurdles can improve efficiency and understanding in manufacturing processes.

What are the common challenges in implementing ISO geometry?

Challenges include understanding complex designs, inconsistent naming, and training issues.

The Future of ISO Geometry in Milling Cutters

Emerging trends in milling cutter technology.. Predictions for future ISO standards developments..The world of milling cutters is changing fast. New technology is making them better and smarter than ever. Right now, trends show that automation and smart materials are becoming popular. These changes help machines work more efficiently.

Looking to the future, we might see new ISO standards. These could improve how we name milling cutter geometries. Predictions suggest that standards will adapt to meet energy efficiency and precision needs. This means less waste and more quality in our work.

- Increased use of smart technology.

- Focus on environmental sustainability.

- Better naming systems based on user needs.

What trends are shaping milling cutter technology?

Emerging trends like automation and smart materials are leading the way. These changes make milling cutters more efficient and precise.

What will future ISO standards look like?

- Standards may prioritize energy efficiency.

- Improved naming systems could become common.

- Quality control will be emphasized.

Conclusion

In summary, the milling cutter ISO geometry naming structure helps us understand cutter design. It includes important details like size, shape, and angles. Knowing this system makes it easier for you to choose the right cutter for your projects. Always explore more resources or articles to enhance your skills and understanding of milling tools. Happy learning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Iso Geometry Naming Structure:The ISO geometry naming structure helps us understand how milling cutters work. Each part has a special name and code. This makes it easy for us to pick the right tool. If you ever see a number, it tells you about the shape or size. Knowing this helps us do our work better!

Sure! Please share the question you want me to answer.

What Is The Significance Of The Iso Geometry Naming Structure In The Classification Of Milling Cutters?The ISO geometry naming structure helps us understand different milling cutters easily. Each part of the name tells us something important, like the shape or size. This makes it simple for us to choose the right cutter for our projects. Using this system, we can talk clearly about tools, helping everyone work better together.

How Does The Iso System Categorize The Various Geometrical Features Of Milling Cutters, Such As Cutting Edge Shape And Number Of Flutes?The ISO system helps us understand different shapes and features of milling cutters. It tells us about the cutting edge shape, like if it’s sharp or flat. It also shows how many flutes, or grooves, are on the cutter. More flutes can mean faster cutting. This way, you can choose the right cutter for your work!

Can You Explain The Components Of An Iso Code For A Specific Type Of Milling Cutter And How Each Part Contributes To Its Identification?An ISO code helps us understand what kind of milling cutter we have. The first letters tell us the shape, like if it’s flat or curved. The numbers show the size, like how big the cutter is. Other letters can describe special features, like if it’s for hard materials. Each part of the code helps us know exactly what the cutter can do.

In What Ways Does Understanding The Iso Geometry Naming Structure Benefit Manufacturers And Machinists In Selecting The Appropriate Milling Cutter For A Specific Application?Understanding the ISO geometry naming system helps you pick the right milling cutter. Each name tells you important details, like shape and size. This means you can find the best cutter for your job quickly. You avoid mistakes and save time and money. Overall, it’s like having a special guide to help you choose!

How Does The Iso Geometry Naming Structure Compare To Other Classification Systems Used In The Machining Industry, And What Are The Advantages Or Disadvantages Of Using Iso?The ISO geometry naming system helps us understand machine parts clearly. It is used around the world, which makes it easier to share ideas. Other systems can be confusing and different in each country. The main advantage of ISO is that it creates a common language for everyone. However, it can be a bit complex at first for new learners.