Have you ever wondered what makes a milling cutter last longer? The secret often lies in the material hardness chart used to choose the right cutter. Choosing the right milling cutter can be a game-changer for any project. It can save time, money, and frustration.

Imagine cutting through metal like slicing through butter. Sounds great, right? The right hardness in a milling cutter helps achieve that smooth cut. Not all milling cutters are created equal. Understanding the hardness of materials can help you pick the best tool for the job.

Did you know that some materials are softer and wear out faster? Others are tougher and can handle heavy use. A hardness chart shows you exactly how different materials stack up against each other. This can guide you in making smart choices for your projects.

In this article, we’ll explore the milling cutter material hardness chart. You’ll learn how to use it to make better decisions. Get ready to discover tips that can make your cutting tasks easier and more effective!

Milling Cutter Material Hardness Chart: Understanding Key Metrics

Milling Cutter Material Hardness Chart

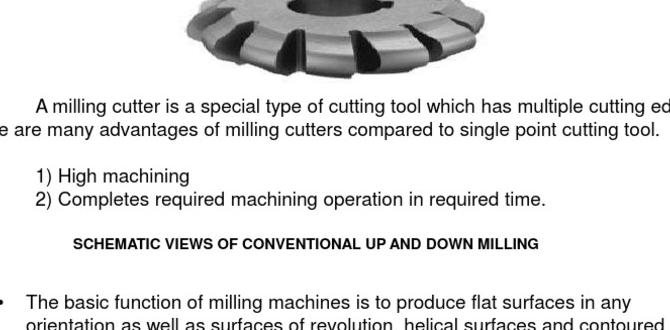

Milling cutters come in various materials, each with different hardness levels. Understanding this hardness chart is important for choosing the right cutter. For example, high-speed steel (HSS) is tough but softer, while carbide is harder and more durable. This knowledge helps you select the best tool for your project, whether you’re crafting something simple or tackling a complex design. Did you know that the right milling cutter can improve precision and extend tool life?2. Common Materials Used in Milling Cutters

Description of various materials such as HighSpeed Steel (HSS), Carbide, and Cobalt.. Pros and cons of each material in relation to hardness and application..Two common materials for milling cutters are High-Speed Steel (HSS) and Carbide. HSS is tough and can withstand high temperatures, making it great for flexible jobs. However, it’s not as hard as Carbide. Carbide, on the other hand, is like the superhero of cutter materials—it’s very hard and wears slowly. But, it can be brittle, like a cookie that crumbles under pressure. Here’s a quick comparison:

| Material | Hardness | Pros | Cons |

|---|---|---|---|

| HSS | Moderate | Flexible, Versatile | Less hard |

| Carbide | High | Durable, Long-lasting | Brittle |

In short, HSS is good for general use, while Carbide shines in complex tasks, but remember to handle it gently!

4. Hardness Chart for Common Milling Cutter Materials

Detailed chart showcasing hardness values for different milling cutter materials.. Comparison of hardness values across various materials..In the world of milling, knowing the hardness of your cutter materials is key. A hardness chart can be your best friend here. It shows you the toughness of different materials, helping you choose the right one for your job. Did you know that harder materials usually last longer? That’s like choosing a pet rock over a fluffy puppy. Let’s take a look at how various cutter materials stack up in terms of hardness:

| Material | Hardness (HRC) |

|---|---|

| High-Speed Steel (HSS) | 60-65 |

| Cemented Carbide | 80-85 |

| Inconel | 45-55 |

| Diamond | 90+ |

This chart makes it easier to compare hardness values. For instance, cemented carbide is much tougher than high-speed steel. Choosing the right material can save you time and effort. So, pick wisely, or you might end up with a cutter that quits on you faster than a kid eating ice cream in the summer sun!

5. Factors Influencing Cutter Material Selection

Discussion on choosing materials based on machining requirements and environments.. How workpiece materials, speeds, and feeds impact cutter effectiveness..Choosing the right material for milling cutters depends on several key factors. Workpiece materials play a big role in this decision. For example, harder materials need tougher cutting tools. Speeds and feeds also matter. Using high speeds can improve cutting but might wear out the cutter faster. Here are some important points to consider:

- Machining requirements: Different jobs need different cutter materials.

- Workpiece material hardness: Match cutter hardness to the part being worked on.

- Cutting conditions: Extreme heat or pressure can influence performance.

Always check the milling cutter material hardness chart to find the best match!

What should I know about cutter material selection?

Cutter material selection challenges include matching hardness to various workpiece needs and managing speed and feed conditions.

6. Best Practices for Maintaining Cutter Hardness

Tips on storage, cleaning, and care for maintaining milling cutter integrity.. Techniques for sharpening and reconditioning milling cutters for prolonged use..Keeping your milling cutters sharp and ready is important for good work. Here are six best practices to help. First, make sure to store your cutters in a dry place. A cool, clean area keeps them safe. Next, always clean them after use. This wipes away dirt and helps them last longer. To sharpen your cutters, use a proper sharpening tool. This can help restore their shape and sharpness. Regular maintenance can save time and money.

How can I improve my milling cutter maintenance?

You can follow storage, cleaning, and proper sharpening techniques to improve your milling cutter maintenance.Additional Tips:

- Keep the cutters dry and dust-free.

- Use a soft cloth for cleaning.

- Sharpen at the right angle.

7. Future Trends in Milling Cutter Material Development

Insight into advancements in material science and manufacturing techniques.. Predictions on emerging materials and their potential hardness benefits..Exciting changes are ahead in milling cutter materials! Thanks to clever scientists and clever machines, we might see new materials that can handle tougher jobs. Imagine cutters made from super strong stuff that stays sharp longer. With these advancements, hardness may take a giant leap! Think of it like a superhero for your cutting tools. Here’s a peek at what we might see:

| Material | Predicted Hardness | Benefit |

|---|---|---|

| Carbide Composites | 85-90 HRC | Longer Life |

| Diamond Coatings | 90+ HRC | Extreme Durability |

| Advanced Steels | 70-80 HRC | Cost-Effective |

So, buckle up! The future looks sharp, and your tools might get an upgrade worthy of a sci-fi movie. Let’s see which material will take the lead!

8. Frequently Asked Questions about Milling Cutter Materials

Common queries regarding hardness and material selection in milling.. Clarification of misconceptions related to cutter hardness and performance..Many people wonder about the right milling cutter materials. One big question is, “Does cutter hardness really matter?” The answer is a big yes! Hardness affects performance, like a superhero’s strength. Another common query is about the best materials for different tasks. Don’t worry! There’s a chart to make it easy. Some think softer cutters wear out faster, but that’s not always the case! The secret lies in matching the cutter to your job.

| Material | Hardness | Best Use |

|---|---|---|

| HSS | High | General purposes |

| Cobalt | Very High | Heavy-duty tasks |

| Carbide | Super High | Precision work |

Conclusion

In conclusion, understanding a milling cutter material hardness chart helps you choose the right tool for your projects. Harder materials last longer and cut better but can be more expensive. We encourage you to explore different materials and their uses. By doing this, you’ll make smarter choices and improve your milling skills. Happy milling!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Material Hardness:Sure! Here are five related questions about milling cutter material hardness: 1. What is milling cutter material hardness? Milling cutter material hardness tells us how tough a cutter is. The harder it is, the longer it lasts. 2. Why is hardness important for milling cutters? Hardness is important because it helps cutters work better. A hard cutter can cut through tough materials without breaking. 3. What materials are used to make hard milling cutters? Cutter materials can include steel and carbide. These are strong and can handle lots of use. 4. How do we know if a milling cutter is hard? We can test hardness with special tools. They measure how well the cutter resists scratches or cuts. 5. Can I use a hard cutter for all jobs? Not always! Hard cutters are great for tough jobs but may not work well on soft materials.

Sure! Please ask your question, and I’ll be happy to help.

What Are The Common Materials Used For Milling Cutters, And How Do Their Hardness Levels Compare?Common materials used for milling cutters are high-speed steel (HSS), carbide, and even cobalt. High-speed steel is tough but not as hard as carbide. Carbide is very hard and can cut through tough materials. Cobalt is harder than HSS but not quite as hard as carbide. Each material works well for different jobs, depending on how hard the material is that we’re cutting.

How Does The Hardness Of A Milling Cutter Material Affect Its Performance And Durability During Machining?The hardness of a milling cutter is really important. Harder materials stay sharp longer while cutting. This means they can work better and last more time before needing to be replaced. If a cutter is too soft, it might wear out quickly and not cut well. So, choosing a hard milling cutter can help you do a good job for a longer time!

What Is The Significance Of The Rockwell Hardness Scale In Evaluating Milling Cutter Materials?The Rockwell hardness scale helps us know how tough a milling cutter is. A higher number means it’s harder and can cut better. When we choose materials for cutters, we want them to be strong. This makes cutting easier and lasts longer. So, the scale is important for picking the best tools for work.

How Does Coating On Milling Cutters Influence Their Hardness And Cutting Efficiency?Coatings on milling cutters make them harder and help them cut better. A hard cutter stays sharp longer, which means you don’t have to change it as often. The coating also reduces the heat when cutting, so the tool works smoothly. This helps you finish your work faster and with less effort!

What Factors Should Be Considered When Selecting A Milling Cutter Material Based On Hardness For Specific Machining Applications?When picking a milling cutter, think about the material you’ll be cutting. Harder materials need harder cutters. You should also consider how fast you want to cut. A tougher cutter can last longer but might cost more. Always match the cutter to your machine and the job you want to do.