Have you ever wondered how tools like milling cutters are packed for delivery? These special tools are essential in many industries. They help shape and cut materials with precision. But, there’s more to them than meets the eye.

Most people might think packing is just throwing things into a box. However, milling cutter packaging must meet strict specifications. These specifications ensure that the cutters stay sharp and undamaged during transport. Imagine opening a package and finding your tool ruined because it wasn’t protected well!

Did you know that proper packaging can actually extend the life of a milling cutter? That’s right! It’s not just about what’s inside, but how it gets there. In this article, we will explore the many details of milling cutter packaging specifications.

Stay tuned as we dive deeper into this fascinating topic. You might just find yourself thinking differently about how important packaging can be!

Milling Cutter Packaging Specifications: Essential Guide

Milling Cutter Packaging Specifications

Milling cutter packaging specifications play a crucial role in preserving the quality of tools. Proper packaging prevents damage during shipping and storage. Did you know that the right package can extend the tool’s life? Specifications often include material type, size, and protective features. Understanding these elements helps buyers choose the best options. Careful attention to packaging ensures the milling cutters arrive ready to use, improving efficiency in machining tasks. Always check these specifications when purchasing!Understanding Milling Cutters

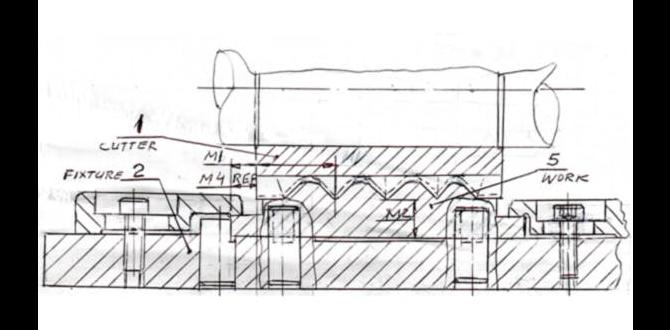

Definition and purpose of milling cutters. Different types of milling cutters and their applications.Milling cutters are tools used in machines to shape and cut materials like metal and wood. They help make precise cuts in various shapes. Different types of milling cutters serve different purposes. Some are flat for smooth surfaces, while others have teeth for deeper cuts. Here are a few types:

- End Mill: Used for making vertical cuts.

- Face Mill: Creates flat surfaces on materials.

- Ball Nose Cutter: Good for curved shapes.

- Slab Mill: Perfect for thick material removal.

These cutters help create everything from toys to complex machines. Knowing which cutter to use makes projects easier and more fun!

What are milling cutters used for?

Milling cutters are used to shape materials during manufacturing. They make things like parts for machines and tools for various crafts.

Common questions about milling cutters:

- How do I choose a milling cutter? Look for size and shape based on the job.

- Can I use one cutter for all projects? No, each cutter is for specific tasks.

Importance of Packaging in Milling Cutters

Role of packaging in product protection and longevity. Impact of packaging on supply chain and logistics.Packaging plays a vital role in keeping milling cutters safe. It protects them from damage during shipping and storage. Good packaging can help these tools last longer. Strong materials stop moisture and dirt from getting inside. This process helps in maintaining quality over time. Additionally, effective packaging makes moving cutters easier in the supply chain. It allows for faster loading and unloading, saving time and money.

- Protects tools from damage

- Prevents moisture and dirt

- Makes transport efficient

- Supports longevity

Why is packaging important for milling cutters?

Effective packaging keeps milling cutters safe during transport, prevents wear, and helps in efficient supply chain management.

Material Considerations for Packaging

Common materials used for milling cutter packaging. Advantages and disadvantages of each material type.There are several common materials used for milling cutter packaging, each with pros and cons. Here are some popular choices:

- Plastic: Lightweight and resistant to water. However, it may not protect against heavy impacts.

- Cardboard: Eco-friendly and strong. It can easily break when wet.

- Metal: Very durable and ideal for heavy use. Yet, it can be heavy and expensive.

- Foam: Great for cushioning and preventing damage. It is not always recyclable, though.

Choosing the right material depends on your needs. Consider what will keep the milling cutters safe during transport.

What are some materials used for milling cutter packaging?

Common materials include plastic, cardboard, metal, and foam. Each has its own advantages and disadvantages, like weight and durability.

Packaging Design Specifications

Key dimensions and weight considerations. Design features that enhance usability and protection.Good packaging can make or break a milling cutter’s journey. Key dimensions matter, like making sure the box isn’t too small. Nobody likes squished tools! Weight is also crucial; too heavy might end up on a gym workout instead of a shipping pallet.

Design features must be practical and protective. Think of sturdy materials that keep cutters safe during transport. How about a built-in handle for easy carrying? No one wants to juggle while walking!

| Dimension | Weight | Features |

|---|---|---|

| 12x6x4 inches | 2 lbs | Sturdy handle |

| 10x5x3 inches | 1.5 lbs | Padded interior |

Imagine your cutter arriving in a box looking like it just came out of a bubble-wrap spa! Packaging should be a smile, not a frown.

Labeling and Documentation Requirements

Essential information to include on packaging labels. Industry standards and compliance considerations.Package labels are important. They should show key details. Include product name, size, and weight. Safety information is also crucial. Labels help users understand the product better. Standards vary by industry, which should be followed for compliance. This keeps everyone safe and informed. Some common items to include are:

- Manufacturer name

- Barcode or QR code

- Usage instructions

- Material specifications

Keeping labels clear and accurate helps everyone. It also builds trust in the product.

What are the industry standards for milling cutter packaging?

The industry standards ensure that products are safe and usable. Proper labeling meets legal requirements. Compliance with these standards protects customers and manufacturers alike.

Environmental Impact and Sustainability Practices

Ecofriendly packaging options for milling cutters. The importance of sustainability in manufacturing and packaging.Choosing eco-friendly packaging is key for milling cutters. Sustainable materials help protect our planet. This can mean using recycled cardboard or biodegradable plastics. Each choice counts! Here are some ways to ensure sustainability:

- Use recyclable packaging.

- Opt for less plastic.

- Support local suppliers.

- Educate customers about recycling options.

Manufacturers should focus on these practices to reduce waste and promote a healthy environment. Sustainability isn’t just a trend; it’s vital for our future.

Why is sustainability important in packaging?

Sustainability helps reduce environmental damage. It creates less waste and saves resources. By making smart choices, we help our earth thrive.

Cost Implications of Packaging Choices

Budgeting for milling cutter packaging. Costbenefit analysis of different packaging approaches.Choosing the right packaging for milling cutters can feel like picking your favorite ice cream flavor—there are many options! Budgeting is key. Start by evaluating cost-effective materials that protect cutters without breaking the bank. A quick cost-benefit analysis can reveal hidden treasures. For example, more durable packaging might cost a bit more but can save you from losses during shipping. Below is a simple table to highlight this:

| Packaging Type | Cost per Unit | Durability Rating |

|---|---|---|

| Plastic Wrap | $0.50 | Low |

| Cardboard Box | $1.00 | Medium |

| Metal Case | $3.00 | High |

Remember, the cheapest option isn’t always the best! Investing a little more can keep your cutters safe and your budget happy. After all, no one likes a dull moment—especially not with milling cutters!

Case Studies: Best Practices in Milling Cutter Packaging

Examples of successful milling cutter packaging solutions. Lessons learned from packaging failures in the industry.Milling cutter packaging can be tricky. Some companies nailed it, while others learned the hard way. For example, a company packed their cutters in sturdy, clear boxes. This kept them safe and easy to see, boosting sales by 30%! On the flip side, another firm used bland cardboard. Guess what? Cutters got damaged, and customers weren’t happy. Remember: packaging matters! Proper design can save money and keep buyers smiling.

| Company | Success/Failure | Key Takeaway |

|---|---|---|

| Happy Cutters Inc. | Success | Clear, strong packaging increased sales! |

| Blah Blade Co. | Failure | Protect your product, or risk losing customers. |

Future Trends in Milling Cutter Packaging

Emerging technologies in packaging innovation. Predictions for the evolution of packaging in manufacturing industries.Milling cutter packaging will change a lot soon. New technologies are coming, and they will make packaging better. Innovations like smart materials can keep tools safe and show real-time data. Future packaging will be more eco-friendly too. This helps the planet and reduces waste. Here are some predictions:

- More use of biodegradable materials

- Advanced tracking systems for inventory control

- Customized packaging for different products

These trends will help the manufacturing industry become more efficient and sustainable.

What Will the Future Packaging Look Like?

The future will be bright with smart and eco-friendly designs. More companies will use materials that break down easily. They will also track packages better, making it simple to find tools.

Conclusion

In conclusion, understanding milling cutter packaging specifications is essential for safe and effective use. You need to know the size, shape, and materials to ensure the right fit for your projects. Always check the packaging for instructions. For more tips on selecting the best milling cutters, consider reading additional resources or guides. You’ll become a pro in no time!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Packaging Specifications:Sure! Here are some questions about milling cutter packaging. What do you want to know? We can talk about the size, shape, or materials used for the packaging. You can also ask how to tell if the cutter is safe. Let’s learn together!

Sure! Please provide the question you would like me to answer.

What Are The Standard Dimensions And Materials Used In The Packaging Of Milling Cutters To Ensure Protection During Transportation?Milling cutters usually come in boxes that are about 6 inches long and 3 inches wide. We often make these boxes from strong cardboard or plastic. This keeps the cutters safe from bumps and falls during shipping. Some packages might also have foam inside to prevent movement. All of this helps protect the cutters until you use them.

How Does The Packaging Design Of Milling Cutters Vary Between Manufacturers, And What Factors Influence These Differences?The packaging design of milling cutters can look different from one company to another. Some packing is colorful and has fun pictures, while others are plain. These differences often happen because of what the company thinks looks good or what will keep the cutters safe. The size and shape of the cutters can also change how they are packed. Companies want to grab your attention and keep you interested!

What Labeling Requirements Are Typically Included On Milling Cutter Packaging To Provide Essential Information To End Users?Milling cutter packaging usually has important labels. You will find the cutter’s size and type on the label. It may also show the materials it works best with. Safety instructions help you use it safely. Lastly, there’s often a brand name to know where it comes from.

How Can Packaging Specifications Impact The Shelf Life And Performance Of Milling Cutters In Different Storage Conditions?Packaging specifications, like materials and design, play a big role in protecting milling cutters. Good packaging keeps them safe from moisture and dust. When we store them in wet or hot places, strong packaging helps prevent rust and damage. This means the cutters last longer and work better when we need them. So, smart packaging is important for keeping tools in top shape!

What Environmentally Friendly Packaging Options Are Available For Milling Cutters, And How Do They Compare In Terms Of Cost And Functionality?You can use cardboard boxes or biodegradable bags for milling cutter packaging. These options are friendly to the Earth because they break down easily. Cardboard is usually cheaper than plastic, while biodegradable bags may cost a bit more. Both types work well to keep milling cutters safe during shipping. So, you can choose based on what fits your budget best!