Have you ever wondered how perfect cuts are made in wood or metal? One of the secrets lies in the milling cutter plunge depth control. This tool helps ensure that every cut is just right. Imagine trying to slice a cake without knowing how deep to cut. It’s messy and can ruin the cake!

In the same way, the plunge depth in milling can affect the quality of the finished product. A well-controlled plunge depth can lead to smooth, clean edges. On the other hand, poor control can create rough surfaces and waste materials.

Did you know that adjusting the plunge depth can improve not only the cut quality but also the life of your milling cutter? Just a small tweak can make a big difference. Understanding how to master milling cutter plunge depth control is key for anyone who wants to make precise cuts.

Milling Cutter Plunge Depth Control: Essential Techniques

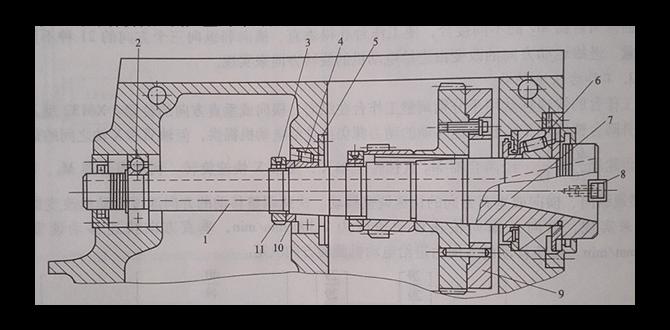

Milling Cutter Plunge Depth Control

Understanding milling cutter plunge depth control can greatly improve your machining skills. It helps in getting accurate cuts while ensuring safety. Did you know that improper plunge depth can lead to tool damage? Adjusting the depth correctly preserves the cutter and enhances surface finish. Imagine saving time and materials just by controlling depth wisely! Learning this technique is essential for any serious machinist. Master it, and you’ll see amazing results in your projects!Understanding Milling Cutter Basics

Definition and types of milling cutters. Importance of plunge depth control in machining processes.Milling cutters are vital tools used in machining. They come in various types, like the end mill, face mill, and slab mill. Each type serves a specific purpose. For example, end mills cut slots and shapes, while face mills create flat surfaces. Plunge depth control is crucial too. It helps ensure accuracy in cutting. A defined plunge depth prevents damage to both the cutter and the material. This control leads to smoother cuts and better results.

What are milling cutter types?

There are several milling cutter types:

- End Mill

- Face Mill

- Slab Mill

- Ball Nose Mill

Why is plunge depth control important?

Plunge depth affects cut quality and tool life. Accurate control leads to better surface finishes and prevents tool wear. This is especially important in tight spaces, where precision counts.

The Fundamentals of Plunge Cutting

Explanation of plunge cutting techniques. Advantages of plunge cutting over other methods.Plunge cutting is a special technique used in machining. It allows the tool to go straight down into the material. This way, the cuts are cleaner and more precise. Plunge cutting offers benefits over other methods. For example:

- It creates less waste.

- It saves time in setup.

- It requires fewer passes to finish a job.

Many find it easier to control the depth of cuts too. This gives workers confidence and helps them create better projects.

What are the advantages of plunge cutting?

Plunge cutting can speed up work. It minimizes errors and improves results. Many users prefer this method for its simplicity and effectiveness. It helps get jobs done quickly!

Factors Influencing Plunge Depth Control

Material properties and their impact on cutting depth. Machine settings that affect plunge depth accuracy.Different factors affect how deep a milling cutter can plunge into material. First, the properties of the material are key. Hard materials require more power, which can limit plunge depth. Soft materials, on the other hand, let you go deeper without much fuss. Next, machine settings are crucial too. If the speed or feed rate isn’t right, plunge depth can suffer. The wrong settings can make a milling cutter act like it’s got a mind of its own!

| Factor | Impact on Plunge Depth |

|---|---|

| Material Hardness | Harder materials restrict depth. |

| Feed Rate | High feed rates can limit depth. |

| Speed Settings | Incorrect speeds affect accuracy. |

Techniques for Achieving Optimal Plunge Depth

Best practices for setting plunge depth on CNC machines. Manual adjustments and considerations for depth control.For the best results in plunge depth on CNC machines, consider these practices:

- Set depth carefully to avoid damage.

- Test with different materials for adjustments.

- Use feed rates that match the material type.

- Monitor the machine during use.

- Consult manuals for specific guidelines.

Manual adjustments are key. Think about the size of the cutting tool. Smaller tools need less depth. Too deep can cause breakage. Pay attention and make changes as needed. This way, you’ll achieve the best performance.

What are the common mistakes in plunge depth control?

Many users forget to check their settings. Not aligning tools properly leads to poor cuts. Proper training can prevent these errors. Always double-check your depth and setup before starting. Remember, a little care goes a long way!

Common Challenges in Plunge Depth Control

Identifying and addressing depth control issues. Solutions for achieving consistent plunge depth.Controlling plunge depth can be tricky. Problems often arise from tool wear or incorrect settings. This can lead to uneven cuts and waste of material. Understanding these issues is key. Here are some solutions:

- Check tool sharpness regularly.

- Adjust machine settings before each use.

- Use depth gauges for accuracy.

- Practice depth control techniques.

With attention to detail, you can achieve consistent plunge depth and improve your work quality.

What are common plunge depth control problems?

Common problems include inconsistent depth and tool breakage. Addressing these issues early helps maintain smooth operation and better results.

Real-World Applications of Plunge Depth Control

Industries that benefit from precise plunge depth control. Case studies highlighting successful plunge depth management.Many industries use precise plunge depth control for better results. For example, in automotive manufacturing, it helps create perfect engine parts. In woodworking, it ensures smooth cuts in furniture. One company, XYZ Corp, improved their production by 30% after mastering this technique. Here’s how various sectors benefit:

| Industry | Benefit |

|---|---|

| Automotive | Improved engine precision |

| Woodworking | Sleek furniture designs |

| Aerospace | Lightweight and strong parts |

Want to hear some numbers? Companies using plunge depth control often see a 20% increase in product quality. It’s like turning a regular pizza into a gourmet one, all thanks to a little attention to depth!

Future Trends in Milling Cutter Technologies

Innovations in milling cutter design for improved depth control. Predictions for the future of machining precision and efficiency.Milling cutter technologies are changing fast. New designs help control plunge depth better than ever. This means machines can cut sharper and deeper without mistakes. In the future, we can expect more efficient and precise machining. Here are some innovations:

- Smart Sensors: These tools help monitor depth as you cut.

- Advanced Materials: Stronger materials make cutters last longer.

- AI Technology: Machines learn from past cuts to improve accuracy.

The future looks bright for milling cutters. As these technologies improve, they will make machining easier and more reliable.

What are smart sensors in milling technology?

Smart sensors are special tools that track how deep the cutter goes during work. They help keep everything on track and improve quality.

Conclusion

In summary, controlling the plunge depth of a milling cutter is crucial for quality work. It helps prevent damage and improves precision. You should always adjust the depth based on the material you’re cutting. Remember to practice regularly to master this skill. For more tips, check out articles or videos on milling techniques. Happy milling!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Plunge Depth Control:Milling cutter plunge depth control helps us decide how deep we want to cut into a material. It’s important so we don’t cut too deep and ruin our piece. We need to set this depth carefully, so our cuts are clean and safe. By using the right tools and settings, we can get the best results in our work. Always remember to check your depth before starting!

Sure! Just ask your question, and I will give you a short and easy answer.

What Are The Key Factors That Influence The Optimal Plunge Depth For A Milling Cutter During Operation?The best plunge depth for a milling cutter depends on a few things. First, consider the material you are cutting. Different materials need different depths. Next, think about the cutter’s size and shape. A larger cutter can go deeper, while a smaller one must stay shallower. Lastly, your machine’s power matters. If it’s strong, you can cut deeper safely.

How Can Operators Ensure Consistent And Accurate Plunge Depth When Using A Cnc Milling Machine?To make sure the plunge depth is the same every time on a CNC milling machine, you can follow a few steps. First, check the machine’s settings before you start. Second, use the same tool and keep it sharp. Third, measure the plunge depth carefully with a ruler or gauge. Finally, practice so you build a steady hand, and you’ll get better at it!

What Role Does Cutting Tool Geometry Play In Determining The Maximum Plunge Depth Achievable Without Damaging The Cutter Or The Workpiece?Cutting tool geometry means the shape and angles of the tool’s edges. This shape helps the tool cut smoothly and evenly. If the shape is wrong, the tool can break or the workpiece can get damaged. By having the right geometry, you can push deeper without causing problems. So, good design helps us work better and safer!

How Can Advanced Milling Machine Features, Such As Depth-Sensing Technology, Enhance Plunge Depth Control During Milling Operations?Advanced milling machines can help us do better work. Depth-sensing technology uses special sensors to feel how deep we are cutting. This way, we can make the cuts just right. It helps us avoid mistakes and gives us more control. With this tech, we can create smoother and more precise shapes in our projects.

What Are The Common Challenges Faced By Machinists When Controlling Plunge Depth, And What Techniques Can Be Employed To Mitigate These Issues?Machinists often struggle with getting the plunge depth just right. Sometimes, the tool might go too deep or not deep enough. This can happen if the machine isn’t set up properly or if the material is tricky to cut. To fix this, you can double-check your settings and use a helper tool to guide the depth. Practicing and taking your time also really helps!