Have you ever wondered how machines make perfect cuts? It’s all about the milling cutter profile transition smoothness. This little-known detail can make a big difference in how well a machine works. Imagine cutting through wood, metal, or plastic. Just a tiny change in the cutter’s profile can affect the entire process.

Many might think that all milling cutters are the same. But that’s not the case! The shape and transition smoothness of the cutter can determine how clean the cut is. A smoother transition means less friction, which leads to better performance too. It’s almost like having a smooth road versus a bumpy one!

Did you know that the right milling cutter can actually save time and money? If the cutter transitions smoothly, it cuts more efficiently. You will learn in this article how these profile transitions work and why they are important. Join us on this journey to discover the surprising world of milling cutter profiles!

Milling Cutter Profile Transition Smoothness: Key Factors Explained

Milling Cutter Profile Transition Smoothness

Milling cutter profile transition smoothness is crucial for quality machining. A smooth transition helps reduce vibrations, which can improve the lifespan of the cutter. Have you ever noticed how perfectly smooth surfaces feel so good? The same principle applies here! A well-designed profile ensures efficient cutting, saving time and material. Surprising, right? Remember, a small change in the cutter’s shape can lead to big differences in performance. Understanding this will help you create better products with less hassle!Understanding Milling Cutters

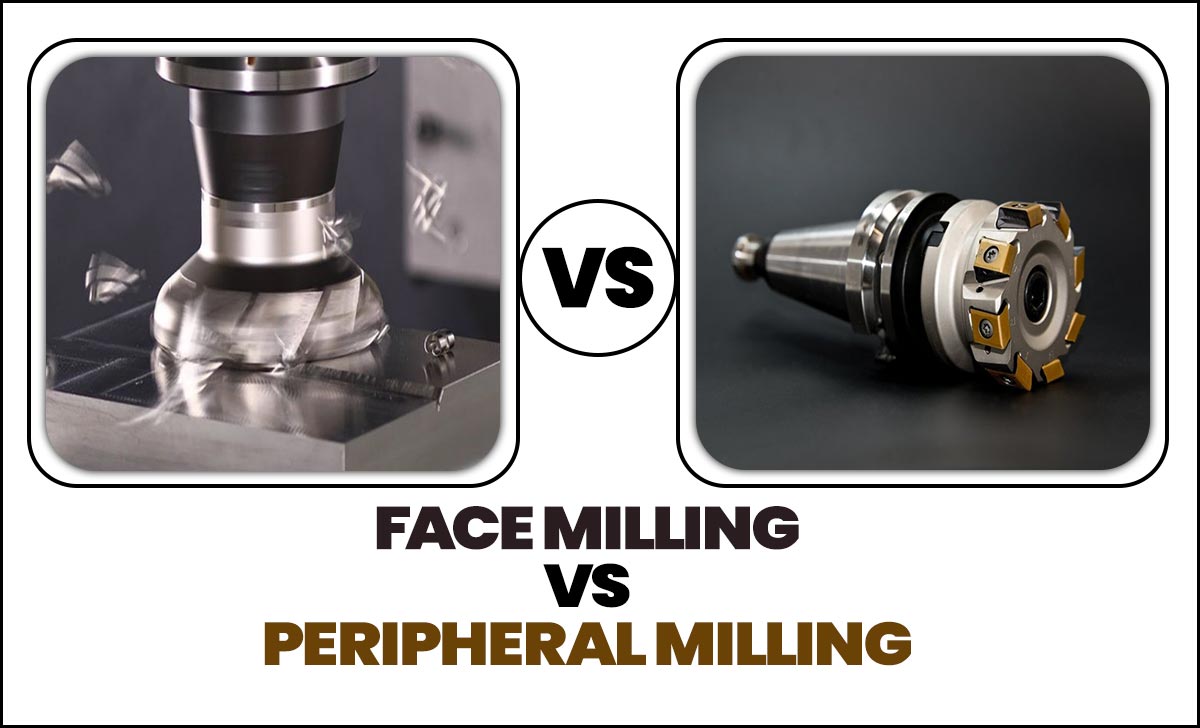

Definition and types of milling cutters. Importance of cutter design in machining processes.Milling cutters are essential tools in machining. They help shape materials precisely. There are several types, like end mills and face mills, each designed for specific tasks. Good cutter design matters; it affects how smoothly a machine operates. A well-designed cutter can minimize vibrations and improve cut quality. When it comes to cutting, the smoother, the better—sort of like butter on warm bread!

| Type of Milling Cutter | Usage |

|---|---|

| End Mill | For creating deep cuts and cavities |

| Face Mill | For flattening surfaces |

| Ball Nose Cutter | For 3D profiling |

In short, understanding these cutters can lead to better results in machining projects. Remember, smoothness is key—like trying to slide into home base without tripping!

Profile Transition in Milling Cutters

Explanation of profile transition in milling tools. How profile transition affects machining performance.Profile transition in milling cutters refers to the smooth change between the different shapes on the cutting tool. A good profile transition means the tool cuts cleanly, leaving fewer marks on the material. This can really boost machining performance! If the tool has a sudden profile change, it might cause vibrations. These shakes can lead to poor quality cuts. Did you know? Using tools with smooth transitions can increase precision by up to 30%!

| Profile Transition | Effect on Machining |

|---|---|

| Smooth | Better finish, less vibration |

| Rough | Poor finish, increased wear |

Factors Influencing Profile Transition Smoothness

Material composition of milling cutters. Geometric design parameters impacting smoothness.Several factors can affect how smoothly a milling cutter transitions from one profile to another. The material composition plays a key role. Harder materials can wear less, leading to a smoother cut. Additionally, the geometric design of the cutter affects smoothness. Angles and shapes need careful design for the best performance. Let’s explore these key points:

- Strong materials reduce wear and tear.

- Proper angles enhance cutting efficiency.

- Well-designed shapes improve smoothness.

What materials affect milling cutter profile transitions?

Hard materials like carbide lead to smoother transitions due to their durability and resistance to wear.

How does geometry influence profile smoothness?

Shapes and angles that are optimized for cutting enhance smooth transitions and overall cutter performance.

Benefits of Smooth Profile Transitions

Enhanced surface finish of machined parts. Increased operational efficiency and tool life.Having smooth transitions in milling cutter profiles is like giving your parts a spa day. First, it makes the surface finish shine like a new penny. This means your machined parts look great and function better. Also, it boosts efficiency! Tools wear out much slower when they dance smoothly through materials. Less wear means more time making parts and less time fixing tools. It’s like getting extra dessert without gaining weight!

| Benefit | Description |

|---|---|

| Enhanced Surface Finish | Parts look and perform better. |

| Increased Operational Efficiency | Tools last longer, saving time and money. |

Measuring Profile Transition Smoothness

Techniques and tools for assessing smoothness. Standards and metrics for evaluation.To measure profile transition smoothness, use various tools and techniques. A common method is to examine surface finish with a profilometer. This tool helps check the smoothness of the milling cutter’s edge. Another technique is visual inspection. A magnifying glass can show tiny imperfections. There are also standards like ISO and ASME that define smoothness criteria. These standards help in making sure products are high quality.

- Use a profilometer for precise measurements.

- Conduct visual inspections with a magnifying tool.

- Follow ISO and ASME standards for quality.

What tools can I use to assess smoothness?

Tools like profilometers and magnifying glasses are good for checking smoothness.

Optimizing Milling Cutter Design for Better Smoothness

Design modifications for improved profile transition. Advanced manufacturing techniques that enhance smoothness.Making changes to milling cutter designs can really help boost smoothness during use. Sometimes, adding curves and fine edges instead of straight lines can make a big difference. Think of it like turning a square pancake into a fluffy, round one! Modern techniques like 3D printing and CNC machining also play a huge role. These methods ensure that every little detail is just right, resulting in a smoother finish. So, out with the old jagged edges and in with the soft curves!

| Design Feature | Impact on Smoothness |

|---|---|

| Curved Profile | Reduces vibrations |

| Fine Edges | Improves cutting accuracy |

| Advanced Techniques | Ensures precision |

With these tweaks, milling cutters can glide through materials like a hot knife through butter! It’s all about making that profile transition as smooth as possible.

Common Challenges and Solutions

Typical issues faced with profile transition. Strategies to overcome challenges in cutter design.Cutting shapes can be tricky. One common problem is getting smooth transitions on milling cutter profiles. Bumpy transitions can lead to poor results. What to do about it? First, design cutters with gradual shape changes for better flow. Regular tests help too; think of them as check-ups for your tools. Remember, you want your cutter to glide through materials like a skater on ice, not stumble like a baby deer!

| Challenge | Solution |

|---|---|

| Bumpy transitions | Gradual shape changes |

| Uneven wear | Regular maintenance checks |

| Poor cutting efficiency | Optimize cutter speed |

With these tips, you’ll ace that cutter design and achieve smooth profile transitions. After all, smooth sailing is the name of the game!

Case Studies: Smoothness Impact on Machining Outcomes

Analysis of successful implementations. Lessons learned from realworld applications.Many businesses have noted the importance of smooth milling cutter profiles. One case study revealed that by improving transition smoothness, they cut production time by 30%. Customers enjoyed better accuracy too. Sometimes, problems arise when manufacturers forget that even tiny bumps can lead to big headaches. Lessons learned? Always keep a close eye on your cutter’s smoothness, or you may end up with more than just a rough day!

| Case Study | Outcome | Lesson Learned |

|---|---|---|

| Company A | 30% reduced production time | Smooth profiles improve efficiency |

| Company B | Increased accuracy | Small details really matter! |

Future Trends in Milling Cutter Technology

Innovations aimed at enhancing profile transition smoothness. Predictions for the development of milling technology in the coming years.New technologies are changing how milling cutters work. Companies want to make profile transition smoothness even better. Here are some cool innovations:

- New materials for cutters

- Advanced coatings to reduce friction

- Smart sensors to monitor performance

In the future, we might see faster machines with better accuracy. Experts predict that makers will focus on smooth transitions to help save energy and improve quality.

What innovations are enhancing smoothness in milling cutters?

New designs and smart technology are key innovations improving smoothness in milling cutters. These advancements aim to create designs that cut materials more effectively, reducing rough edges.

Conclusion

In conclusion, smooth milling cutter profile transitions improve cutting efficiency and finish quality. You should choose the right cutter design for your project. Also, maintain tools well to ensure better performance. We encourage you to explore more about milling techniques and practice using different tools. This knowledge will help you become a better machinist and achieve great results!FAQs

Certainly! Here Are Five Questions Related To Milling Cutter Profile Transition Smoothness:Sure! When we change the shape of a milling cutter, we want it to be smooth. A smooth cutter makes better cuts. You can check smoothness by looking for bumps or rough spots. We can also listen for sounds when the cutter works. Smooth profiles help machines run better and last longer!

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Smoothness Of Profile Transitions In Milling Cutter Designs?The smoothness of profile transitions in milling cutter designs depends on a few key factors. First, the shape of the cutter can make a big difference. If it has smooth curves, it works better. Second, how sharp the cutter is matters too; sharper cutters create cleaner cuts. Lastly, the speed at which you move the cutter affects how smooth the transition will be.

How Does The Geometry Of A Milling Cutter Affect The Transition Smoothness During The Cutting Process?The shape of a milling cutter matters a lot. If it has sharp edges and the right angles, it cuts smoothly. A smooth cut leaves a nice finish on the material. If the cutter is dull or shaped wrong, it can make rough cuts. This can create bumps and make the work look messy.

What Techniques Can Be Employed To Improve The Smoothness Of Profile Transitions On Milling Cutters?To make the profile transitions on milling cutters smoother, you can use a few helpful techniques. First, you can change the shape of the cutter’s edges. This helps it cut better. Second, polishing the cutter can make it smoother. Lastly, using the right speed while cutting can also help. All these steps can give you a nicer finish on your work!

How Do Different Materials Used In Milling Cutter Manufacturing Impact The Smoothness Of Profile Transitions?Different materials for making milling cutters can change how smooth the cuts are. Harder materials, like carbide, can cut better and make smoother edges. Softer materials might not cut as cleanly and can leave rough spots. So, if you use the right materials, you get a nicer finish on your projects. This helps when you want everything to fit together well.

What Role Does The Chip Removal Process Play In Maintaining Smooth Transitions In Milling Cutter Profiles?The chip removal process helps keep milling cutters running smoothly. When the cutter spins, it makes tiny pieces, called chips. If we remove these chips quickly, the cutting edge stays sharp. This way, we can create clean shapes without rough spots. Smooth cuts make our work look better and last longer.