Have you ever watched a chef finely slice vegetables? It looks easy, but there’s a trick to it. In the same way, when using milling cutters, the ramp angle and engagement depth are key to achieving the best results.

But what exactly do these terms mean? The ramp angle affects how smoothly the cutter slices into the material. Meanwhile, engagement depth determines how deep the cutter goes into the workpiece. These factors can make a big difference in performance.

Did you know that even small changes in ramp angle can lead to better cuts? Just like adjusting the angle of your knife can help chop faster, milling cutters need the right settings. Understanding milling cutter ramp angle vs engagement depth can help you improve your projects.

Whether you’re a hobbyist or a professional, mastering these concepts is important. Imagine creating the perfect piece of work without wasting time and materials. Sounds great, right? Let’s dive deeper into how these two elements interact and why they matter so much!

Milling Cutter Ramp Angle vs Engagement Depth

Understanding milling cutter ramp angle and engagement depth can improve machining results. The ramp angle influences how the cutter approaches the workpiece. A larger ramp angle can reduce cutting forces and improve surface finish. Engagement depth, on the other hand, defines how deeply the cutter interacts with the material. Choosing the right combination helps avoid tool wear and enhances efficiency. Did you know that small adjustments in these angles can lead to big changes in performance?

What is Ramp Angle in Milling?

Definition of ramp angle in the context of milling. Importance of ramp angle in effective milling operations.

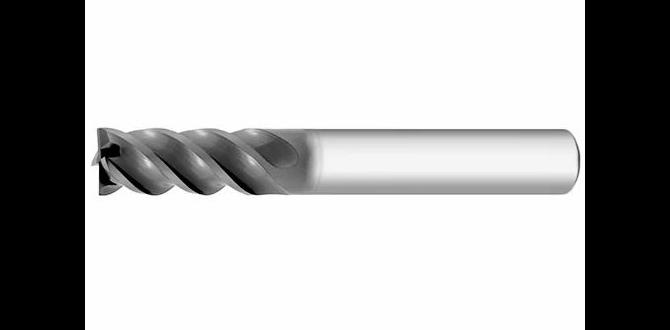

The ramp angle in milling shows how the cutter moves up or down on a surface. It helps create smoother cuts and reduces tool wear. This angle is important for several reasons:

- Improved Efficiency: A proper ramp angle lets the cutter engage with the material smoothly.

- Better Surface Finish: It helps create cleaner and more precise cuts.

- Reduced Tool Damage: A good angle can lower the risk of breaking or wearing down the tool.

Using the right ramp angle makes milling safer and better.

What is the impact of ramp angle on milling?

The ramp angle directly affects how well the cutter performs. A suitable ramp angle ensures that the cutter engages the material effectively. This leads to better cuts and longer tool life.

Understanding Engagement Depth in Milling

Definition of engagement depth and its significance. How engagement depth affects cutting performance and tool longevity.

Engagement depth describes how deeply the cutting tool enters the material. Imagine a kid sinking a spoon into a bowl of ice cream; the deeper the spoon goes, the more ice cream it scoops! This depth is important because it directly affects how well the cutter performs. A right balance means better cutting and longer tool life. Too deep? The tool gets stressed. Too shallow? You miss the good stuff! Staying within the golden range keeps everything happy.

| Engagement Depth | Effects on Performance | Tool Longevity |

|---|---|---|

| Low | Poor cutting effectiveness | Increased wear |

| Optimal | Efficient cutting | Extended tool life |

| High | Excessive stress | Reduced lifespan |

Comparative Analysis: Ramp Angle vs Engagement Depth

Key differences between ramp angle and engagement depth. How each parameter influences machining outcomes.

Two important factors in machining are ramp angle and engagement depth. They both change how a milling cutter works. The ramp angle is the angle at which the cutter enters the material. A steeper angle can cause the cutter to push harder and may lead to better finishes. On the other hand, engagement depth is how deep the cutter goes into the material. A deeper cut removes more material but can also create stress. Understanding these differences helps to choose the right settings for better results in machining.

What is the difference between ramp angle and engagement depth?

The ramp angle influences the entry of the cutter, while engagement depth controls how much material is removed.

Key points:

- Ramp Angle: Affects cutting force and surface finish.

- Engagement Depth: Influences material removal and tool wear.

Optimal Ramp Angles for Different Materials

Recommended ramp angles for metals, plastics, and composites. Factors influencing the choice of ramp angle based on material type.

Choosing the right ramp angle can make a big difference. For metals, a ramp angle of 5-7 degrees is often best. This helps to reduce stress on the material. For plastics, consider a 10-15 degree angle. This allows for smoother cuts. Composites work well with angles of 8-12 degrees. These angles help manage heat and avoid damage. Always think about how tough or flexible the material is when selecting the angle.

What affects ramp angle choices?

Material type, tool wear, and speed all play important roles. These factors help determine the best ramp angle for effective cutting.

Key factors include:

- Material hardness: Harder metals need smaller angles.

- Flexibility: Softer plastics can handle larger angles.

- Cutting speed: Faster speeds may require different angles.

Factors Affecting Engagement Depth

Explanation of how machine settings impact engagement depth. Role of tool geometry in determining optimal engagement depth.

Machine settings can really shake things up in the milling world. If you set the speed too fast, the tool might chatter like a nervous squirrel! The geometry of the cutting tool is also super important. A well-designed cutter can slice through material smoothly, maximizing engagement depth safely. It’s like picking the right spoon for your cereal—too big, and you’ll make a mess; too small, and you’ll be there all morning!

| Factor | Impact on Engagement Depth |

|---|---|

| Machine Speed | Increased speeds can cause chatter and reduce engagement depth. |

| Feed Rate | A faster feed rate allows for deeper engagement but can lead to tool wear. |

| Tool Geometry | Sharper edges and optimal angles give you better depth control. |

Effects on Tool Wear and Performance

Analysis of how ramp angle affects tool wear. Impact of engagement depth on tool performance and efficiency.

Ever wonder how a tool survives the tough world of milling? The ramp angle of the milling cutter plays a big role in tool wear. A steeper ramp can increase wear, while a gentler ramp can help the tool last longer. Meanwhile, the engagement depth impacts performance. Too deep can lead to overheating, like your computer during a marathon gaming session!

| Ramp Angle | Effect on Tool Wear |

|---|---|

| Steep | Higher wear rates |

| Gentle | Lower wear rates |

Balancing these elements can boost efficiency and help your milling machine stay cool and happy. In short, manage your ramp angle and engagement depth wisely to keep your tools running longer!

Practical Applications of Ramp Angle and Engagement Depth

Realworld examples of milling operations utilizing ramp angle and engagement depth. Best practices for optimizing these parameters in different industries.

Different industries often use ramp angles and engagement depths for better milling. For instance, in aerospace, low ramp angles allow for smoother cuts, which helps avoid damage. In automotive, using higher engagement depths improves metal removal rates, saving time. Here are some best practices:

- Adjust ramp angles for smoother finishes.

- Use engagement depth to speed up production.

- Monitor tool wear closely for better results.

Optimizing these settings can lead to higher efficiency and lower costs. Smart choices make all the difference!

What is the best ramp angle to use in milling?

The best ramp angle varies but is often around 5 to 10 degrees for steel. This allows for good balance between cutting efficiency and tool wear.

Common Misconceptions about Ramp Angle and Engagement Depth

Debunking myths surrounding ramp angle and engagement depth. Clarifying the relationship between the two concepts.

Many people think that ramp angle and engagement depth are the same. Spoiler alert: they’re not! Ramp angle is how steep the cut is, while engagement depth shows how deep the tool bites into the material. It’s like trying to compare apples and oranges, or maybe more like comparing a cat to a toaster! Understanding their differences can improve your cutting precision. Misunderstanding these concepts can lead to wrong tool choices and extra headaches.

| Concept | Definition |

|---|---|

| Ramp Angle | Steepness of the cut |

| Engagement Depth | How deep the tool engages with the material |

Choosing the right ramp angle and engagement depth can make your milling experience smoother. Remember, ramp angles don’t do the cha-cha while engagement depths dive deep like a cannonball!

Tools and Techniques for Measuring Ramp Angle and Engagement Depth

Recommended tools for accurately measuring ramp angle. Techniques for assessing engagement depth in milling processes.

Measuring ramp angle and engagement depth in milling can be tricky, but the right tools make it fun and accurate! A protractor gage is great for checking ramp angles. Meanwhile, dial indicators can help you assess engagement depth smoothly. Remember, using a caliper might feel like doing a dance—one wrong move, and you’re back to square one! Accurate measurements improve your work, making it as precise as a cat jumping onto a narrow ledge.

| Tools | Purpose |

|---|---|

| Protractor Gage | Measures ramp angle |

| Dial Indicator | Checks engagement depth |

| Caliper | Measures various dimensions |

Future Trends in Milling: Ramp Angle and Engagement Depth Considerations

Exploration of new technologies affecting ramp angle and engagement depth. Predictions for future advancements in milling practices related to these parameters.

As technology evolves, the world of milling is changing fast. New tools are popping up, impacting ramp angle and engagement depth. These tools help cut materials faster and with better precision. Experts predict the future will see even smarter machines. They might let us adjust angles and depths on the fly. This could mean fewer mistakes and more savings! Imagine saying goodbye to those pesky errors—sounds dreamy, right?

| Trend | Description |

|---|---|

| Smart Tooling | Tools that self-adjust for optimal performance. |

| AI Integration | Artificial Intelligence helps in planning cuts better. |

| Adaptive Technology | Machines that learn from past cuts to improve future ones. |

Conclusion

In summary, the ramp angle of a milling cutter affects how deep it engages with the material. A better ramp angle can lead to smoother cuts and less wear on tools. You can improve your machining skills by experimenting with different angles. For more insights, check out articles on milling techniques and practice regularly to see the benefits firsthand!

FAQs

How Does The Ramp Angle Of A Milling Cutter Affect The Cutting Forces Experienced During Machining Operations?

The ramp angle of a milling cutter changes how hard it pushes against the material. When the angle is steeper, the cutter can dig in more, causing stronger forces. A smaller ramp angle makes it easier to cut, reducing those forces. So, if you change the ramp angle, it can make cutting easier or harder!

What Are The Optimal Ramp Angles For Various Materials To Minimize Tool Wear While Maximizing Efficiency In Milling Operations?

To keep tools safe and working well in milling, we use different ramp angles for different materials. For soft materials like aluminum, a ramp angle of about 5 to 10 degrees is good. For harder materials like steel, a ramp angle of 2 to 5 degrees is better. These angles help the tool cut smoothly, which means it lasts longer and works faster. Remember, the right angle helps you get the best results!

How Does Changing The Engagement Depth Of The Milling Cutter Influence The Stability And Vibration Of The Machining Process?

When you change how deep the milling cutter goes into the material, it affects how steady the machine is. If you cut too deep, the machine can shake more. This shaking is called vibration. It makes it harder to get a smooth cut. So, a shallower cut usually means less vibration and better stability.

What Role Does The Ramp Angle Play In Chip Formation And Evacuation During Milling, And How Can It Impact Surface Finish?

The ramp angle helps the cutting tool slice better through the material. When we adjust the angle, it makes tiny pieces, called chips, come off smoothly. This way, the chips don’t get stuck and can escape easily. If the chips are removed well, the surface we create is smoother and nicer. So, the ramp angle is important for both cutting and making a good finish on the surface!

How Can Cnc Programming Techniques Be Adjusted To Effectively Manage Ramp Angle And Engagement Depth For Complex Milling Geometries?

To manage the ramp angle and engagement depth in CNC programming, you can adjust the settings in the program. First, choose a gentle ramp angle so the tool cuts smoothly. Next, set the right depth for your cuts, so it doesn’t go too deep too fast. This helps the machine work better with tricky shapes. You can test your settings and make changes until everything runs nice and easy.