Have you ever watched a machine slice through metal? It’s fascinating how tools like milling cutters work. These cutting tools help create amazing shapes and designs. But did you know they can also create problems like chatter? Chatter is that annoying noise when a tool vibrates too much. It’s not just noisy; it can ruin your work.

Understanding milling cutter regenerative chatter limits is important. It helps ensure smooth operations. Imagine trying to draw with a shaky pencil. It just doesn’t work! When chatter happens, it might ruin a perfect piece of metal or wood.

In this article, we will explore what regenerative chatter is and why it matters. Have you ever wondered how engineers solve this problem? Let’s dive in and discover the secrets behind smoother cuts and better results.

Milling Cutter Regenerative Chatter Limits Explained Here

Milling Cutter Regenerative Chatter Limits

Milling cutter regenerative chatter limits are crucial in machining. These limits help reduce vibrations during cutting, improving surface quality. Have you ever wondered how machines create smooth finishes? The key lies in controlling these chatter limits. When chatter occurs, it can ruin a part. Understanding these limits allows engineers to select the right cutter and settings. This not only saves time but also enhances the lifespan of tools. Curious about how you can apply these insights?What is Regenerative Chatter?

Definition and explanation of regenerative chatter in milling.. Importance of understanding chatter for machining efficiency..Imagine trying to balance a spoon on your finger—it’s tricky, right? That’s kind of like what happens with regenerative chatter in milling. This funny phenomenon occurs when vibrations during cutting start to grow instead of quieting down. Think of it as a dance gone wrong! Understanding chatter is key for machining efficiency. If we can control it, things run smoother and faster. A smooth operation means less wasted time and money!

| Aspect | Effect of Chatter |

|---|---|

| Machining Quality | Lower surface finish |

| Tool Life | Reduced lifespan |

| Production Rate | Decreased efficiency |

Causes of Regenerative Chatter in Milling Cutters

Analysis of dynamic forces affecting the milling process.. Material properties and their role in chatter generation..Dynamic forces play a big role in milling. They can push or pull on the cutter, causing vibrations. These vibrations are linked to regenerative chatter. Different materials can also affect this chatter. For example, soft materials might make less noise, while hard ones can buzz more. Here are some key points:

- Hard materials create more vibrations.

- Soft materials allow smoother cuts.

- Cutter speed can increase chatter risks.

What affects chatter in milling cutters?

Chatter happens because of machine parts moving against the material. Changes in speeds and materials can spark these vibrations.

Factors Influencing Chatter Limits

Role of cutting speed, feed rate, and depth of cut.. Machine rigidity and tool stability contributions..Several factors affect milling cutter regenerative chatter limits. First, cutting speed plays a crucial role; higher speeds can reduce vibrations. Next, feed rate impacts stability. A slower feed usually means less chatter. Similarly, the depth of cut matters, too. Deeper cuts can increase chatter risk. Also, machine rigidity and tool stability are key. Strong machines and stable tools help cut smoothly, reducing disruptive vibrations.

What are the key influences on chatter limits?

Cutting speed, feed rate, depth of cut, machine rigidity, and tool stability all influence chatter limits.

Key Factors:

- Cutting Speed: Higher speeds often lead to less chatter.

- Feed Rate: Slower rates can reduce vibrations.

- Depth of Cut: Deeper cuts may increase chatter risks.

- Machine Rigidity: Stronger machines support smoother cutting.

- Tool Stability: Firmly held tools prevent vibrations.

Identifying Chatter Symptoms

Visual and auditory indicators of chatter during machining.. Measuring vibrations and their significance in diagnosing issues..Chatter during machining can be tricky to spot, but there are some clear signs. Look for visible vibrations in your machine or notice if the sound gets weird—like a cat meowing on a bad day! If you hear grinding or high-pitched noises, it might be a red flag. Measuring vibrations is key too. It helps diagnose issues before they become headaches. Most machines give off signals, so tuning in can save you time and money.

| Symptoms | Indicators |

|---|---|

| Odd sounds | Grinding or high-pitched noises |

| Visible vibrations | Shaky parts of the machine |

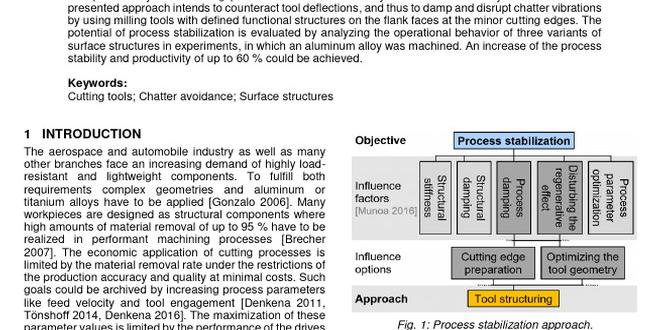

Techniques to Mitigate Regenerative Chatter

Adjusting cutting parameters for optimal performance.. Utilizing advanced tooling designs and materials..To tackle regenerative chatter, fine-tuning your cutting parameters is key. Adjusting speed and feed rates can significantly improve your milling experience. A little tweak here and there can make a big difference—like a magician pulling a rabbit from a hat! Next, consider advanced tooling designs. They are like super-suits for your cutters, made from super-sleek materials that fight off chatter like a superhero. Want to know more? Check the table below for quick insights on optimal settings!

| Parameter | Optimal Range |

|---|---|

| Cutting Speed | 500-1000 RPM |

| Feed Rate | 0.1-0.3 mm/rev |

Case Studies and Success Stories

Examples of successful chatter mitigation in industrial settings.. Lessons learned from machining failures and improvements..Many factories have tackled the pesky issue of chatter. One team used a simple change in cutter speed, and it worked wonders! Chatter dropped by 50%, making the workers do a happy dance. Another company learned the hard way. They saw parts fail due to poor planning. They fixed their mistakes by using better tools and training. The result? Parts were perfect, and the team was smiling. Let’s look at some examples.

| Company | Chatter Mitigation Technique | Success |

|---|---|---|

| Factory A | Speed Adjustment | 50% reduction in chatter |

| Factory B | Improved Training | Zero defective parts |

Future Trends in Milling Cutter Design

Innovations aimed at reducing chatter susceptibility.. Potential impact of new materials and technology on milling..New designs for milling cutters are buzzing with exciting innovations! Engineers are focusing on tools that reduce chatter, which can cause a noisy ruckus during milling. Innovations like vibration-damping materials help keep things smooth and steady. Imagine milling without the annoying chatter; it’s like a quiet library!

New technologies are also popping up! Advanced materials can make cutters tougher and lighter. This means better performance and longer life. With these improvements, machining will be more efficient and cost-effective.

| Innovation | Impact |

|---|---|

| Vibration-Damping Materials | Reduces chatter |

| Advanced Materials | Enhances durability |

| Smart Technology | Improves efficiency |

Faster cutting speeds and better quality are just the start of what’s possible. Buckle up for a smoother journey in the world of milling!

Conclusion

In summary, understanding milling cutter regenerative chatter limits helps you improve your machining processes. This knowledge enhances tool performance and reduces wasted materials. You can explore adjustments like feed rates and spindle speeds to minimize chatter. For deeper insights, consider reading more about vibration control and advanced milling techniques. We can all make our work smoother and more efficient!FAQs

What Factors Contribute To The Onset Of Regenerative Chatter In Milling Operations, And How Can They Be Identified?Regenerative chatter happens when the cutting tool and the material vibrate together. This can start if the tool is dull or if it moves too fast. We can spot chatter by listening for strange sounds or feeling bumps during cutting. Checking the tool and adjusting the speed can help prevent it.

How Can The Stability Lobe Diagram Be Utilized To Determine The Chatter Limits For A Specific Milling Cutter And Workpiece Setup?We can use a stability lobe diagram to see how a milling cutter works with a specific workpiece. This diagram shows safe speeds and depths for cutting. If we stay within these limits, we avoid loud, unwanted vibrations called chatter. By checking the diagram, we can choose the best settings for smooth and safe cutting. This helps our work turn out better!

What Role Does The Spindle Speed Play In Affecting The Regenerative Chatter Limits During Milling?Spindle speed is how fast the cutting tool spins. When we change the spindle speed during milling, we can affect chatter. Chatter is a shaking that makes cutting less smooth. If we find the right speed, we can reduce chatter and make better cuts. So, spindle speed helps us keep our work steady and clean!

How Can Advanced Machining Strategies, Such As Adaptive Control Or Variable Speed Adjustments, Mitigate The Effects Of Regenerative Chatter?Advanced machining strategies help reduce a problem called regenerative chatter, which is like a wobble when machines cut materials. With adaptive control, the machine can change how it cuts right away to stay steady. Variable speed adjustments let the machine speed up or slow down to avoid the chatter. This keeps the cuts smooth and makes the work better. So, using these strategies helps us make good, clean cuts without annoying vibrations.

What Are The Most Effective Techniques For Measuring And Analyzing Regenerative Chatter In Milling Processes, And How Can These Insights Inform Cutter Selection?To measure regenerative chatter in milling, you can use special tools that show vibrations. We can also record sounds while milling to find problems. These measurements help us understand how the tool is working. By analyzing this data, you can choose the right cutter for smoother milling. This way, you can avoid chatter and make better cuts.