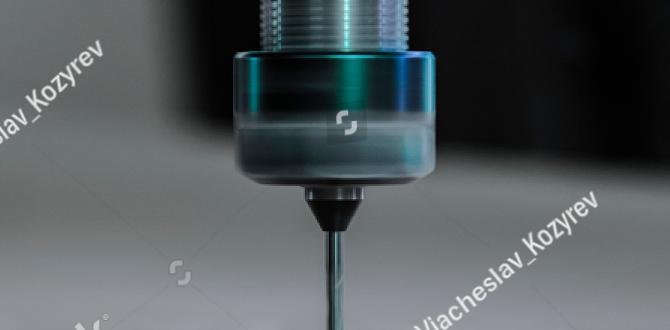

Have you ever wondered how some machines cut metal so smoothly? It’s often thanks to a special tool called a milling cutter. These tools help shape and cut materials in factories. But there’s one thing that makes them even better: cooling.

Imagine using a knife to slice through ice cream on a hot day. Without cooling, the knife might get too warm and messy. The same thing happens with milling cutters. When they work hard, they heat up. That’s where milling cutter spindle cooling integration comes into play. It keeps everything running smoothly.

Did you know that improperly cooled cutters can ruin work pieces? They can even break. This is why the right cooling methods are super important. As we dive deeper into this topic, you’ll discover how these coolers keep machines sharp and efficient. Let’s explore how cooling integration helps in the world of milling!

Milling Cutter Spindle Cooling Integration: Boosting Efficiency

Milling Cutter Spindle Cooling Integration

Milling cutter spindle cooling integration helps machines run smoothly. This cooling system keeps the spindle temperature low during cutting. Why is this important? A cool spindle means better performance and longer life. Imagine a tired worker needing a break; the spindle needs that too! Proper cooling prevents wear and tear, making machining more efficient. It’s interesting that attentive cooling can boost production and quality. This technology showcases how small changes can lead to big improvements in manufacturing.Types of Cooling Systems for Milling Cutters

Description of different cooling methods: air, oil, and liquid cooling.. Pros and cons of each cooling system type in terms of efficiency and cost..Cooling systems help keep milling cutters from overheating. There are three main types: air, oil, and liquid cooling. Each system has its benefits and drawbacks.

- Air Cooling: Uses air to cool the cutter. It is cheap but not very strong.

- Oil Cooling: Uses oil to absorb heat. It is effective but can be expensive.

- Liquid Cooling: Uses a special liquid for cooling. It is very efficient but costs more than air or oil.

Choosing the right cooling method can save money and improve efficiency. For best results, consider efficiency and cost before deciding.

What are the benefits of each cooling method?

Air cooling is affordable and simple. Oil cooling is effective and can handle high heat. Liquid cooling provides the best performance and efficiency. Knowing these can help choose the right system for milling cutter needs.

Benefits of Integrated Cooling Systems

Enhanced tool life and performance through effective heat management.. Improved machining accuracy and surface finish due to temperature stabilization..Integrated cooling systems offer many perks for machining. They help tools last longer and perform better by keeping heat in check. This means fewer trips to the tool shop and more time making stuff! Additionally, with stable temperatures, machining accuracy improves, leading to smoother surfaces. Think of it like giving your tools a refreshing drink instead of making them sweat it out! Here’s a quick look at the benefits:

| Benefit | Description |

|---|---|

| Enhanced Tool Life | Reduces wear, making tools last longer. |

| Improved Performance | Helps tools work better overall by managing heat. |

| Better Accuracy | Stable temperatures lead to precise cuts. |

| Smoother Surfaces | Gives a neat finish, like polishing your favorite toy! |

Key Factors for Successful Cooling Integration

Importance of spindle design compatibility with cooling systems.. Considerations for coolant selection and delivery methods..Cooling systems are vital for the spindle’s performance and lifespan. Design compatibility between the spindle and the cooling system affects efficiency. Proper fit ensures that coolant flows effectively. Choosing the right coolant is also key. It should match the spindle’s material and function. Delivery methods matter too. Some systems use mist, while others use liquid. Each has its benefits. Keep these factors in mind to optimize the milling cutter spindle cooling integration.

Why is spindle design important for cooling systems?

The spindle design ensures proper alignment and flow of coolant, maximizing efficiency and preventing overheating.

Considerations for Coolant Selection

- Material compatibility

- Cooling efficiency

- Environment impact

Delivery Methods

- Mist systems

- Liquid systems

- Airflow assistance

Case Studies: Successful Implementation of Cooling Integration

Examples of industries that have adopted spindle cooling integration.. Analysis of results achieved through these implementations (e.g., increased productivity, reduced tool wear)..Many companies have seen great results by using spindle cooling integration. For instance, the automotive and aerospace industries have adopted this technology. The outcomes speak for themselves:

- Increased productivity: These companies can make parts faster.

- Reduced tool wear: Tools last longer, saving money.

- Better quality: Machined parts have fewer defects.

For example, a factory reported a 30% boost in production after using cooling systems. This positive change helps companies work smarter and more efficiently.

Why is spindle cooling integration important?

Spindle cooling integration is crucial because it helps machines run smoothly. It keeps them cool and allows for faster cutting. This results in high-quality work without breaking tools easily.

Challenges and Solutions in Spindle Cooling Integration

Common challenges faced during the integration process, such as cost and complexity.. Practical solutions and best practices for overcoming these challenges..Milling cutter spindle cooling can be tricky. Many face hurdles like high costs and added complexity. But don’t worry! Here are practical solutions:

- Evaluate different cooling methods.

- Choose cost-effective materials.

- Use simulation tools to plan well.

These steps can ease the integration process. Remember, starting small can help manage costs!

What are some common challenges in spindle cooling integration?

One main challenge is high expenses. Another is increased system complexity. Finding efficient cooling solutions can require careful planning and design.

Best Practices

- Consider modular setups.

- Train your team on maintenance.

With these tips, you can tackle challenges head-on and improve your spindle cooling setup!

The Future of Spindle Cooling Technologies

Emerging technologies and innovations in spindle cooling methods.. Predictions on how these advancements could shape the milling industry..New spindle cooling methods are popping up like dandelions in spring! Innovations like self-cooling spindles and liquid nitrogen systems promise to keep machines cool while boosting efficiency. Imagine a milling cutter that stays chill – it could make work faster and save energy too! In the future, these tech wonders might not just heat things up in the workshop but also cool heads, as they improve productivity. Who knew being cool could be so hot?

| Technology | Benefits |

|---|---|

| Self-Cooling Spindles | Reduced heat, more efficiency |

| Liquid Nitrogen Systems | Extreme cooling, less downtime |

Conclusion

In conclusion, integrating cooling in milling cutter spindles improves performance and tool life. Cool spindles cut better and last longer, saving you time and money. Remember to check your spindle cooling system regularly. You can explore more about this topic online to enhance your machining skills. Let’s keep our tools cool and efficient for the best results!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Spindle Cooling Integration:I’m sorry, but it looks like I don’t have the specific questions you’re talking about. If you share those questions with me, I can help answer them in a simple way!

Sure! Please give me the question you’d like me to answer, and I’ll be happy to help!

What Are The Most Effective Cooling Methods For Milling Cutter Spindles, And How Do They Impact Machining Accuracy And Tool Life?The best ways to cool milling cutter spindles are using water, air, or special oils. These coolers help keep the spindle from getting too hot while working. When the spindle stays cool, it can make better cuts, which means more accuracy in our work. Also, cooler tools last longer, so you won’t need to replace them as often. This saves time and money!

How Can The Integration Of Cooling Systems In Milling Cutter Spindles Improve Thermal Management And Reduce Thermal Deformation During Operation?Cooling systems in milling cutter spindles help keep them cool while they work. When we cool the spindle, it doesn’t heat up as much. This helps to stop it from changing shape, which can happen when things get too hot. With less bending or changing, the cuts we make are smoother and more accurate. So, cooling makes everything work better and last longer!

What Role Does Coolant Type (E.G., Oil-Based Vs. Water-Based) Play In The Efficiency Of Spindle Cooling Systems In Milling Applications?The type of coolant you use in milling machines can really matter. Oil-based coolants keep things slick and can cool better than water-based ones. Water-based coolants are easier to clean up. However, if you need strong cooling power, oil-based might be best. Choosing the right coolant helps the machine work well and last longer!

How Can Sensors And Monitoring Technology Be Utilized To Optimize The Performance Of Cooling Systems Integrated Into Milling Cutter Spindles?We can use sensors to check the temperature of milling cutter spindles. If the temperature gets too high, the sensors send alerts. This helps us know when to cool things down. Monitoring technology also tracks how well the cooling system works. By watching this data, we can make the cooling systems even better and keep everything running smoothly.

What Are The Potential Challenges And Solutions When Implementing Cooling Integration In Existing Milling Machine Designs?Using cooling systems in old milling machines can be hard. First, we might need to change the machine’s design, which can be expensive. Also, finding the right spot for the cooling system is tricky. To solve this, we can work with experts who know about machines and cooling. We can also test small changes before making big ones. This way, we can make sure everything works well together.