Have you ever wondered how machines cut through metal so smoothly? Milling cutters play a big role in that process. These tools help shape materials into the right form. But did you know that the speed at which they spin is super important?

Understanding the milling cutter spindle speed formula can help us unlock better cutting results. It’s like a secret recipe! If we get the speed right, we can improve efficiency and reduce mistakes.

Imagine a baker who mixes the perfect amount of ingredients. They can create delicious treats. In the same way, choosing the right spindle speed can create clean cuts and great finishes on metal pieces.

Many people overlook this vital formula. But, once you grasp it, you’ll see how it fits into the bigger picture of machining. Are you ready to dive in and discover how to calculate that perfect spin speed? Let’s get started!

Understanding Milling Cutter Spindle Speed Formula Efficiently

Understanding the milling cutter spindle speed formula is essential for efficient machining. This formula helps determine the right speed for cutting materials effectively. Imagine you’re baking cookies. If the oven is too hot, your cookies might burn. The same idea applies to milling. If the spindle runs too fast or slow, it can damage your workpiece. The formula typically includes the diameter of the cutter and the cutting speed. Knowing this can improve your machining skills and ensure smoother finishes. It’s like finding the right speed for your bike; it makes all the difference!

Understanding the Basics of Spindle Speed

Definition of spindle speed in milling operations. Importance of spindle speed in machining efficiency and tool life.

Spindle speed is how fast a milling cutter rotates during a job. Think of it as the speed of a bicycle wheel when you pump your legs. A suitable spindle speed improves machining efficiency and helps tools last longer. If it’s too slow, it can take more time. If it’s too fast, tools may wear out quickly. Keep the right speed for the best results!

Why is spindle speed important?

Spindle speed affects how well the tool works. Higher speeds can cut quicker but may damage the tool. Lower speeds can keep tools safe but slow down the process. Balancing speed is key!

Key Points:

- Speed boosts machining efficiency.

- Right speed extends tool life.

- Adjusting speed can save costs.

The Role of Milling Cutters in Spindle Speed

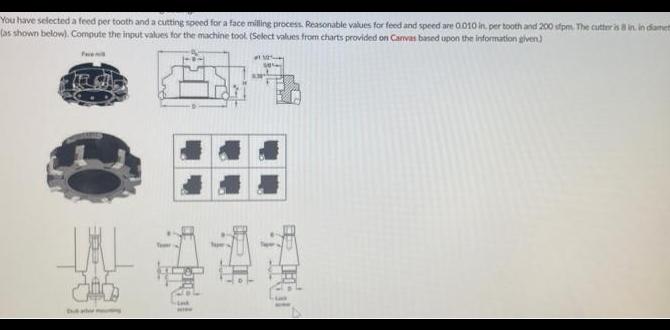

Different types of milling cutters and their applications. How cutter design influences spindle speed requirements.

Milling cutters come in different shapes and sizes, each with a special job. For example, a flat cutter slices smoothly, while a ball cutter chases curves. The cutter’s design can change how fast the spindle should spin. If a cutter’s teeth are big, the spindle might need to turn slower. But if the teeth are tiny, zooming at high speed keeps things cool. This balance is key to making perfect cuts without melting metal!

| Cutter Type | Application |

|---|---|

| Flat Cutter | Used for smooth surfaces. |

| Ball Cutter | Great for rounding edges. |

| End Mill | Versatile for various cuts. |

Factors Affecting Spindle Speed in Milling

Material properties of the workpiece. Type of milling operation (e.g., face milling, slab milling).

Many things affect how fast the spindle spins in milling. The material properties of the workpiece matter. Hard materials need slower speeds to avoid damage. Softer materials can handle faster speeds. The type of milling operation also plays a role. For example, face milling often requires higher speeds than slab milling. Knowing these factors helps in choosing the right speed for your cutter.

What factors impact spindle speed?

Material properties and the type of milling operation affect spindle speed. Different materials and milling types need different speeds for best results.

Key Factors:

- Material Hardness

- Milling Type: Face vs. Slab

The Spindle Speed Formula Explained

Breakdown of the spindle speed formula: N = (CS × 12) / (π × D). Explanation of variables: Cutting speed (CS), Diameter (D), and calculated spindle speed (N).

The spindle speed formula helps us figure out how fast a spindle should rotate. It’s expressed as N = (CS × 12) / (π × D). Here, N is the spindle speed, CS is cutting speed, and D is the diameter of the tool. Imagine telling your friends how fast a roller coaster goes—it’s all about those numbers! The cutting speed (CS) tells us how quickly we want to cut, while D shows how wide the tool is. Think of CS as your speed limit and D as the size of your car—it all matters!

| Variable | Meaning |

|---|---|

| N | Spindle Speed |

| CS | Cutting Speed |

| D | Diameter of Cutting Tool |

Calculating Spindle Speed for Different Materials

Recommended cutting speeds for various materials (steel, aluminum, etc.). How to adjust spindle speed based on material properties.

Different materials need different spindle speeds to cut well. Each one has a unique property that affects how fast the cutter should spin. Here are some recommended speeds:

- Steel: 80-100 feet per minute

- Aluminum: 600-800 feet per minute

- Wood: 4,000-6,000 feet per minute

Choose a lower speed for tougher materials, like steel. Use a higher speed for softer ones, like aluminum. This helps achieve a smooth finish and prolongs tool life.

What is the impact of material properties on cutting speed?

Material properties greatly affect cutting speed. Softer materials cut faster. Harder materials need slower speeds. Always adjust your spindle speed based on the type of material to get the best results.

Real-World Applications of Spindle Speed Calculations

Case studies showcasing optimized spindle speeds in machining. Tools and techniques for accurate spindle speed calculations.

Machining is a precise art, and spindle speed calculations play a huge role in it. Many companies have learned to fine-tune these speeds for better results. For example, a manufacturer found that using the right spindle speed cut production time by 25%! Now that’s what I call a speedy win. Tools like tachometers and software can help figure out the best speeds. They make calculations quicker than a squirrel on caffeine.

| Case Study | Speed Optimization | Improvement (%) |

|---|---|---|

| Company A | Increased spindle speeds | 20% |

| Company B | Adjusted cutting parameters | 30% |

| Company C | Utilized high-speed machining | 25% |

Using spreadsheets can make these calculations as easy as pie (mmm, pie!). Having the right spindle speed can save both time and money. Always remember: the better the calculations, the smoother the machining. So, let’s get those spindles spinning!

Common Mistakes to Avoid in Spindle Speed Calculations

Misestimating cutting speed values. Ignoring tool wear and its impact on spindle speed.

Many people make mistakes in spindle speed calculations. One common error is misestimating cutting speed values. Incorrect values can lead to poor performance. Another mistake is ignoring tool wear. Worn tools can change the cutting speed, affecting results. Always check your tools to ensure they are in good shape. This helps keep your work accurate and safe.

Why is cutting speed important?

It ensures efficiency and prevents damage.

Common mistakes to avoid:

- Using outdated speed values

- Not considering tool condition

- Overlooking material properties

Best Practices for Setting Up Spindle Speed

Steps to take before starting a milling operation. Importance of continuous monitoring and adjustments during machining.

Before starting any milling operation, take some important steps. First, double-check your tools and materials. Ensure everything is ready to go. Next, set the spindle speed correctly to match the task. This helps in getting smooth cuts and saves material. During machining, keep an eye on the process. Continuous monitoring allows you to spot any problems early. Adjustments may be needed to keep everything running smoothly. Here’s a quick list:

- Check tools and materials.

- Set the right spindle speed.

- Monitor the operation closely.

- Make necessary adjustments.

Why is monitoring important during machining?

Monitoring helps catch problems early. It ensures better results and keeps tools from wearing out too fast. Remember, small changes can lead to big improvements!

Conclusion

In conclusion, the milling cutter spindle speed formula helps you determine the right speed for cutting materials. Knowing this formula is crucial for effective machining. We can improve our projects by using the correct spindle speed. For more tips, check out additional resources or tutorials online to enhance your skills. Happy milling!

FAQs

What Is The Formula For Calculating The Spindle Speed (Rpm) Of A Milling Cutter, And What Are The Key Variables Involved?

To find the spindle speed, or how fast the cutter spins, we use this formula: RPM = (Cutting Speed x 12) ÷ (π x Diameter). Here, RPM stands for revolutions per minute. Cutting Speed is how fast the tool should move, and Diameter is how wide the cutter is. You multiply the Cutting Speed by 12 to change it into inches per minute and then divide by the product of π (which is about 3.14) and the Diameter.

How Does The Diameter Of The Milling Cutter Affect The Spindle Speed In Machining Operations?

The diameter of the milling cutter is how wide it is. When the cutter is bigger, it needs to spin slower. This helps prevent breakage and makes better cuts. If the cutter is smaller, it can spin faster. So, we adjust the speed based on the cutter’s size.

What Role Does The Material Being Machined Play In Determining The Appropriate Spindle Speed For A Milling Cutter?

The material you are cutting affects how fast the milling machine can spin. Softer materials like wood need slower speeds, while harder materials like metal can handle faster speeds. If you go too fast with hard materials, you might break the tool or mess up the cut. So, we choose the right speed based on what we are working with. This helps us make smooth, clean cuts.

Can You Explain How To Convert Spindle Speed From Rpm To Surface Speed (Sfm) For Different Milling Applications?

To convert spindle speed from RPM (revolutions per minute) to SFM (surface feet per minute), you first need to know the diameter of the cutting tool in inches. You can use this simple formula: SFM = (RPM × Diameter × π) ÷ 12. Here, π (pi) is about 3.14. This calculation helps you find out how fast the tool moves across the material while you are milling. Remember, you can always ask for help if you get stuck!

What Are The Consequences Of Operating A Milling Cutter At An Incorrect Spindle Speed, And How Can This Affect The Quality Of The Finished Workpiece?

If you use a milling cutter at the wrong speed, the tool can get damaged. It may also create rough marks on the workpiece. This means your final product won’t look or feel good. You might have to redo your work, wasting time and materials. It’s important to use the right speed for the best results!