Have you ever wondered what causes tools to break when they’re working hard? It’s a frustrating problem for many engineers. One common issue is milling cutter surface fatigue failure. This happens when tools wear out too quickly, leading to unexpected breakdowns.

Imagine trying to build something amazing, only to find that your tools keep failing. You might feel stuck and puzzled. This failure not only slows you down but can also increase costs.

Did you know that even tiny cracks on a milling cutter can lead to big problems? These cracks grow slowly, unnoticed at first. Then, one day, the tool can suddenly break. Understanding how this happens can help prevent such failures.

In this article, we will explore milling cutter surface fatigue failure. We will uncover the reasons behind it and share tips to avoid it. By the end, you’ll be better prepared to keep your tools in top shape!

Understanding Milling Cutter Surface Fatigue Failure Causes

Milling Cutter Surface Fatigue Failure

Milling cutter surface fatigue failure can lead to costly production delays. When a cutter wears down, it may crack or break. This happens because of repetitive stress during cutting. Imagine a toy car’s wheels wearing out after too much play! Proper care, like regular checks and using quality tools, can prevent this issue. Understanding these failures helps keep equipment running smoothly and saves money in the long run!Understanding Surface Fatigue Failure

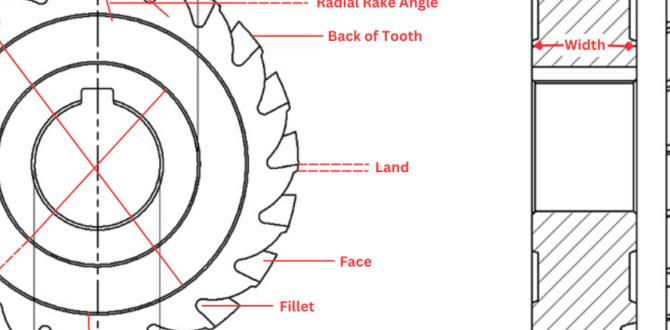

Definition and mechanisms of surface fatigue failure in cutting tools.. Factors contributing to surface fatigue in milling cutters..Surface fatigue failure is what happens to cutting tools when they lose their strength. Imagine your favorite toy; if you use it a lot, it might break! This is similar. In milling cutters, tiny cracks can form when they constantly hit tough materials. These cracks grow over time, leading to tool failure. Factors like high pressure, temperature, and poor lubrication can speed this up. To show you more, here’s a simple table:

| Factors Contributing to Surface Fatigue | Description |

|---|---|

| Pressure | High pressure can cause stress on the tool’s surface. |

| Temperature | Extreme heat can weaken the tool faster than a popsicle on a sunny day. |

| Lubrication | Poor lubrication can make tools work harder, leading to wear. |

So, keeping your milling cutter cool and well-oiled is a smart move. After all, nobody wants a cranky cutting tool!

Common Causes of Surface Fatigue Failure in Milling Cutters

Effects of excessive load and cutting forces.. The role of cutting speed and feed rate on fatigue..Many things can cause milling cutter surface fatigue failure. Two key factors are too much load and cutting forces. High loads can stress the cutting edges, leading to cracks. Cutting speed and feed rate also matter. If they are too high, they push the tool beyond its limits. This can lead to quick wear and damage.

What causes surface fatigue failure in milling cutters?

Excessive load, cutting speed, and feed rate are common causes of surface fatigue failure. Balancing these factors is crucial for extending tool life.

Key Points:

- Excessive load increases stress.

- High cutting speed leads to overheating.

- Inappropriate feed rate causes uneven wear.

Signs and Symptoms of Surface Fatigue Failure

Visual indicators of surface wear and damage.. Performance changes suggesting fatigue failure..It’s important to check for signs of surface fatigue failure in milling cutters. Some visual signs include:

- Cracks on the cutting edges.

- Chips or small pieces missing from the surface.

- Burrs that form along the edges.

Performance changes also indicate fatigue failure. You might notice:

- A decrease in cutting efficiency.

- Higher vibration levels during use.

- More heat generated while cutting.

By watching for these signs, you can catch problems early.

What are common signs of surface fatigue failure?

Common signs include cracks, chips, and burrs on the cutter’s surface. Observing these signs can help prevent bigger issues.

Preventive Measures to Mitigate Surface Fatigue Failure

Best practices for milling cutter usage to extend tool life.. Importance of choosing the right cutting parameters and conditions..Milling cutters are key tools in machining. To extend their life, use them wisely. Follow these best practices:

- Choose the right speed and feed rate. This helps cut smoothly.

- Keep the tools clean and sharp. Dull tools can cause fatigue.

- Use proper coolant. It cools and lubricates during cutting.

- Monitor tool wear regularly. Replace cutters before they fail.

By following these tips, you can greatly reduce milling cutter surface fatigue failure and improve performance.

Why are cutting parameters important?

Cutting parameters affect tool life and job quality. Choosing the right settings lowers stress on tools and improves results.

Inspection and Maintenance Techniques

Recommended methods for inspecting milling cutters for fatigue.. Maintenance routines that can prevent premature failure..Checking milling cutters is key to keeping them sharp and safe. Regular inspections help catch problems early. Look for cracks, wear, and any unusual shapes. Maintaining a schedule is important. Follow these steps:

- Clean the cutters after use.

- Check for dull edges regularly.

- Sharpen as needed to avoid further damage.

- Store cutters properly to prevent rust.

Doing these tasks can help avoid milling cutter surface fatigue failure and keep your tools working longer.

How to inspect milling cutters for fatigue?

You can inspect milling cutters by looking for signs of damage. This includes checking for cracks and wear. Use a magnifying glass to see small details.

Best Maintenance Practices:

- Keep tools clean to avoid rust.

- Store in a dry place.

- Sharp cutters cut better and last longer.

Regular care keeps tools sharp and safe.

Case Studies: Lessons Learned from Surface Fatigue Failures

Analysis of notable failures in milling applications.. Insights gained and strategies developed for future improvements..Several notable failures in milling applications teach us valuable lessons. Investigators found that surface fatigue often caused these issues. They suggested some key strategies for improvement:

- Regular inspections can spot wear early.

- Using better materials can increase cutter life.

- Adjusting speeds and feeds can reduce stress.

These insights help prevent future problems and ensure smooth milling operations. Learning from past mistakes makes the process safer and more efficient.

Why do milling cutters fail?

Milling cutters fail mainly due to surface fatigue, wear, and improper maintenance. These factors can lead to breakages and poor performance. Regular checks and correct usage can prevent such failures, ensuring better results.

Future Trends in Milling Cutter Technology

Emerging materials and coatings to enhance resistance to fatigue.. Innovations in milling cutter design aimed at improving performance and longevity..New materials and coatings are shaking up milling cutter technology. These innovations improve resistance to fatigue, making sure that cutters last longer—even against tough conditions. Imagine a coating that’s tougher than your little brother pretending to be a superhero!

Modern designs focus on performance and endurance. Some cutters now look like they belong in a sci-fi movie, but they really do their job well. Enhanced shapes and features help them zoom through tough materials effortlessly.

| Material/Coating | Benefits |

|---|---|

| Diamond-like Carbon | High wear resistance |

| AlTiN Coating | Better heat resistance |

| Ceramic Inserts | Long tool life |

As technology evolves, milling cutters will keep getting smarter. It’s an exciting future where cutters not only cut but also last—like your favorite chocolate, but without the calories!

Conclusion

In summary, milling cutter surface fatigue failure occurs when tools wear out from repeated use. This can lead to poor cuts and tool breakage. To prevent this, maintain your tools regularly and use the right cutting speeds. You can also explore more about materials and coatings that help reduce wear. Remember, better tools mean better results!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Surface Fatigue Failure:Milling cutters can break or wear out because of surface fatigue failure. This happens when they are used a lot and get tired. You can think of it like when you run a lot and your legs feel sore. Maintaining the cutter by cleaning it and keeping it sharp helps it last longer. You should also follow the right speeds and feeds when using it.

Of course! Please provide the question you’d like me to answer, and I’ll be happy to help.

What Are The Primary Factors That Contribute To Surface Fatigue Failure In Milling Cutters During Machining Operations?Surface fatigue failure in milling cutters happens for a few main reasons. First, heat builds up when cutting materials, which can wear out the cutter. Second, if the cutter gets too much pressure, it can weaken and break. Third, if there’s not enough lubrication, like oil, the cutter can wear faster. Finally, using the cutter on hard materials can cause damage more quickly.

How Can The Choice Of Milling Cutter Material And Coating Influence Its Resistance To Surface Fatigue Failure?The material of a milling cutter affects how strong it is. Hard materials last longer and resist wear better. Coatings can also help by protecting the cutter from damage. When we choose the right material and coating, we reduce the chance of breaking. This means our cutting tools will work better for longer!

What Role Does Cutting Speed And Feed Rate Play In The Onset Of Surface Fatigue Failure In Milling Operations?Cutting speed is how fast the tool moves when it cuts the material. Feed rate is how much the tool moves into the material for each turn. If the cutting speed is too high or the feed rate is too big, it can cause extra wear on the tool and the material. This wear creates tiny cracks, leading to surface fatigue failure. So, we need the right speeds and rates to keep everything working well.

What Inspection And Monitoring Techniques Can Be Employed To Detect Early Signs Of Surface Fatigue Failure In Milling Cutters?To spot early signs of wear in milling cutters, we can use a few techniques. First, we can look for tiny cracks or changes in the cutter’s surface. Next, we can use a special machine that measures vibrations when the cutter is running. If you notice any odd sounds or changes in how the cutter works, that’s also a clue. Regular checks help catch problems early, keeping everything running smoothly.

How Can Proper Maintenance And Tool Management Practices Mitigate The Risk Of Surface Fatigue Failure In Milling Cutters?To keep milling cutters safe, we need to take care of them. You can check them regularly for any damage. Cleaning them helps remove dirt, which can make them wear out faster. Also, using the right tools means they don’t get too hot or stressed. When we manage our tools well, they last longer and work better!