Have you ever wondered how machines make things with such amazing detail? One key part of this process is the milling cutter. It shapes materials with precision. But what makes one milling cutter better than another? The answer lies in something called surface texture.

Surface texture refers to the finish of a cut after the milling process. It can affect how strong or smooth the final product is. When the texture is right, the product looks great and works better. So, how do experts analyze this texture to improve their work? That’s where the fun begins!

Imagine you are a detective, examining clues to solve a mystery. In this case, the clues are tiny bumps and grooves on the surface of materials. By studying these details, engineers can learn a lot about the milling cutter’s performance. You might be surprised to find out how much the right surface texture can change everything!

Join us as we explore the exciting world of milling cutter surface texture analysis. You’ll discover how it improves technology and why it matters to all of us. Let’s dive in!

Milling Cutter Surface Texture Analysis: Insights And Techniques

Milling Cutter Surface Texture Analysis

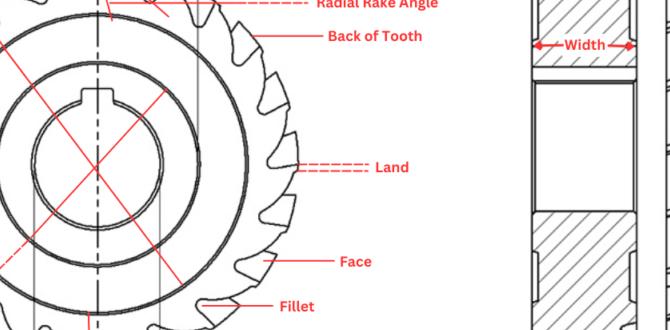

Milling cutter surface texture analysis helps improve the quality of machined parts. It examines the surface left by milling tools and shows how tool design affects final outcomes. Did you know that tiny differences in texture can make big changes in product performance? These insights help manufacturers pick the right tools. Readers learn about measurement techniques and how they impact efficiency. Understanding this can lead to better products and more successful projects in engineering and manufacturing.What is Milling Cutter Surface Texture?

Definition and significance of surface texture. Different types of surface textures in milling cutters.Milling cutter surface texture is vital for making precise cuts. It describes how smooth or rough a cutter’s surface is. The texture affects how well the cutter works. Different textures include:

- Smooth: Reduces friction and heat.

- Rough: Increases grip on materials.

- Patterned: Helps with chip removal.

Understanding these textures helps manufacturers choose the right cutter for each job. This enhances productivity and product quality.

Why is surface texture important?

Surface texture directly impacts cutting performance, tool life, and finished product quality. A cutter with the right texture can improve efficiency and reduce costs.

Importance of Surface Texture in Milling Cutters

Impact on machining performance and workpiece quality. Relation to tool wear and lifespan. “`htmlSurface texture plays a big role in milling cutters. A good surface ensures better machining performance and higher quality workpieces. Did you know that a smoother surface can lead to less friction, making your tools last longer? That means less frequent replacements and more savings!

Also, rough surfaces can lead to increased tool wear. This means your milling cutter might throw a tantrum and need replacing sooner than you think. So, keeping an eye on surface textures can help extend a cutter’s lifespan. Remember, nobody likes a grumpy tool!

| Surface Texture | Impact on Performance | Tool Wear |

|---|---|---|

| Smooth | High quality workpieces | Lower wear rate |

| Rough | Poor machining results | Higher wear rate |

Factors Influencing Surface Texture of Milling Cutters

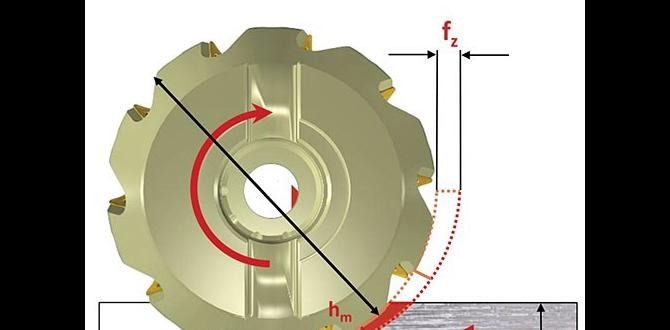

Material composition and hardness. Cutting parameters (speed, feed rate, depth of cut).Many things affect how smooth a milling cutter feels when you use it. First, the materials used to make the cutter play a big role. For example, high hardness can lead to sharper edges, which means better cuts. Then, we have cutting parameters like speed, feed rate, and depth of cut. If you go too fast, the cutter might struggle, and if you cut too deep, well, you might just create a mess!

| Factor | Effect |

|---|---|

| Material Composition | Harder materials yield smoother surface texture |

| Cutting Speed | Too fast can create rough textures |

| Feed Rate | A slower rate often leads to finer surfaces |

| Depth of Cut | Too deep may result in poor surface quality |

In short, pay attention to what your cutter is made of and how you use it to keep things nice and smooth. Remember, a little bit of care can go a long way, like putting cream on your coffee instead of just splashing it everywhere!

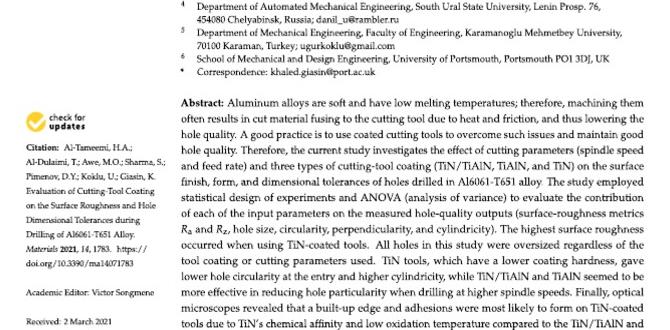

Techniques to Improve Surface Texture

Tool coating and its effects. Optimizing cutting conditions for better texture.Improving surface texture can make a big difference in milling. One way is through tool coating, which protects the cutter and reduces wear. This can lead to smoother surfaces. Another method is to optimize cutting conditions. Using the right speed and feed rate can enhance texture.

- Use the right tool coating for your material.

- Adjust the cutting speed for better results.

- Find the best feed rate to avoid roughness.

What are some benefits of tool coating?

Tool coating can increase tool life and improve surface finish. It protects against heat and wear, helping you create better parts.

How do cutting conditions affect texture?

Cutting conditions like speed and feed rate can make surfaces smoother. The right balance reduces chatter and roughness in your workpiece.

Case Studies in Milling Cutter Surface Texture Analysis

Examples of surface texture analysis in industry applications. Outcomes of improved surface texture on machining performance.In different industries, analyzing the surface texture of milling cutters helps improve machining. For example, in the automotive industry, better surface texture can make parts last longer and fit together perfectly. This means fewer car repairs, which makes everyone happy! Using the wrong cutter can lead to bad textures, and that equals messy jobs and wasted time. In one study, researchers found that improved surface textures boosted cutting speeds by up to 30%. That’s like hitting the turbo button on a go-kart!

| Industry | Outcome of Improved Surface Texture |

|---|---|

| Automotive | Longer-lasting parts and better fits |

| Aerospace | Improved fuel efficiency and reduced weight |

| Medical Devices | Enhanced safety and reliability |

Future Trends in Milling Cutter Technology

Innovations in materials and coatings. Emerging analysis technologies and methodologies.Milling cutter technology is always improving. New materials and coatings make tools last longer and work better. Special coatings can reduce friction and wear, helping tools stay sharp. Emerging analysis technologies also play a big role. They allow us to study how these tools work in real-time. Here are some trends to watch:

- Advanced ceramic materials for increased durability.

- Nanotechnology to create super thin coatings.

- Real-time monitoring with sensors for better performance insights.

What are the benefits of new milling cutter technologies?

New milling cutter technologies improve efficiency, reduce costs, and increase tool life. They help manufacturers produce better products with less waste.

Practical Applications of Surface Texture Analysis in Milling

Realworld benefits in manufacturing processes. Case examples of efficiency and quality enhancements.Analyzing the surface texture of milling cutters brings real benefits to manufacturing. It helps improve efficiency and product quality. Here are some ways this process helps:

- Reduces material waste.

- Increases lifespan of cutting tools.

- Minimizes production delays.

For example, a company used texture analysis to cut costs by 20%. Another found that better texture led to a 30% increase in production speed. These changes make a big difference in how businesses operate.

How does surface texture analysis improve manufacturing?

It helps companies create better products faster, saving time and money. This leads to satisfied customers and a more successful business.

Conclusion

In summary, milling cutter surface texture analysis helps us understand the quality of milling tools. Good texture improves cutting performance and tool life. You can explore different surface textures to see what works best for your projects. We encourage you to read more about this topic and experiment with various milling techniques to enhance your skills!FAQs

How Does The Surface Texture Of Milling Cutters Impact The Overall Machining Performance And Surface Quality Of The Workpiece?The surface texture of milling cutters affects how well they cut. A smooth cutter makes cleaner cuts and leaves a nice finish on the workpiece. If the cutter is rough, it can create bumps and scratches. This means you get a lower quality surface. Good texture helps the cutter last longer too!

What Are The Key Parameters Used To Quantify The Surface Texture Of Milling Cutters, And How Do They Influence Tool Wear?We can measure the surface texture of milling cutters using three key things: roughness, waviness, and lay. Roughness tells us how bumpy the surface is. Waviness shows the bigger patterns on the cutter. Lay describes the direction of the grooves on the cutter. The smoother the cutter, the less it wears out when cutting, helping it last longer.

How Can Advanced Imaging Techniques, Such As Atomic Force Microscopy Or Scanning Electron Microscopy, Be Utilized To Analyze The Surface Texture Of Milling Cutters?We can use advanced imaging techniques like atomic force microscopy (AFM) and scanning electron microscopy (SEM) to look closely at milling cutters’ surfaces. AFM helps us feel the tiny bumps and grooves on the cutter’s surface. SEM gives us clear pictures of the cutter’s surface from different angles. By using these tools, we can learn how the cutter is made and if it is working well. This helps us make better tools for cutting!

What Role Does The Coating Material Of A Milling Cutter Play In Determining Its Surface Texture And Durability During Machining Operations?The coating material on a milling cutter helps it cut better and last longer. It creates a strong surface that can handle heat and wear. This means you can make smoother shapes without breaking the cutter. A good coating also helps the cutter stay sharp, which gives you nicer results in your work.

How Can Surface Texture Analysis Of Milling Cutters Be Integrated Into Predictive Maintenance Strategies To Enhance Tool Life And Machining Efficiency?We can look at the surface texture of milling cutters to help predict when they need maintenance. By checking how smooth or rough the cutter is, we can tell if it’s wearing out. If we notice changes, we can fix or replace tools before they break. This helps the tools last longer and work better. It makes our jobs easier and saves us time and money!