Have you ever wondered how machines make precise cuts in metal? It all comes down to a special tool known as a milling cutter. This tool helps shape and finish materials with amazing accuracy. But to get the best results, we need to understand something important—how to model the forces acting on these tools.

Imagine you’re sculpting a block of clay. You need to know how hard to push and which angle to use to get the best shape. The same idea applies to milling cutter tool force model calibration. By studying how forces work on these tools, we can improve their performance. This leads to cleaner cuts and smoother finishes.

Did you know that even small changes in force can change the result completely? A well-calibrated model helps engineers predict these changes. It’s like having a magic map that tells you the best way to cut. In this article, we will explore the fascinating world of milling cutter tool force model calibration. Get ready to dive into the details!

Milling Cutter Tool Force Model Calibration Techniques Explained

Milling Cutter Tool Force Model Calibration Summary

Calibrating the milling cutter tool force model is crucial for precision in manufacturing. This process involves adjusting models to match actual force measurements during milling. By understanding these forces, engineers can improve efficiency and reduce wear on tools. Did you know that accurate force modeling can save companies significant money by preventing damage? This calibration helps predict tool performance accurately, ensuring smoother operations and better results in machining tasks.Understanding Milling Cutter Tools

Definition and types of milling cutter tools. Importance of milling cutter tools in manufacturing processes.Milling cutter tools are essential for shaping and cutting materials like wood and metal. These tools come in various types, including flat end mills, ball end mills, and corner radius mills. Each type has its unique job, much like superheroes with special powers!

They play a vital role in manufacturing because they help create precise parts. A well-made part can save time and money! Did you know that improper tool usage can lead to a decrease in precision of up to 40%? That’s a huge drop! So, using the right milling cutter is as important as choosing the right ice cream flavor. Nobody wants broccoli swirl, right?

| Type of Milling Cutter | Uses |

|---|---|

| Flat End Mill | Cutting flat surfaces |

| Ball End Mill | Creating rounded edges |

| Corner Radius Mill | Producing fillets |

In summary, milling cutters are like the all-star players in the manufacturing game, making sure everything fits together perfectly!

Fundamentals of Force Models in Milling

Explanation of force models used in milling. The role of cutting force in machining efficiency.Force models show us how much power is needed when cutting materials. They are really important in milling, where we shape metal or wood. Cutting force affects machining efficiency. Stronger cutting force means slower work, while less force makes things go faster. Understanding these models helps to improve tools and save time. Better tools lead to more precise and quick cuts, which is what we want in milling.

What is a force model in milling?

A force model in milling describes how cutting forces change during the machining process. It helps engineers understand how tools behave.

Key Points

- Force models help predict power needs.

- They improve cutting tool design.

- Less cutting force increases speed.

- Efficiency boosts productivity.

Importance of Model Calibration

Why model calibration is essential for accurate results. Benefits of calibrated models in predictive machining.Model calibration is like tuning a musical instrument. If it’s off-key, the results will sound bad! Proper calibration ensures that milling cutter tools give precise outcomes. This accuracy is vital for predictive machining, as it helps avoid costly mistakes. A well-calibrated model can save resources and time, making processes smoother and more efficient. Plus, who wouldn’t want to boast about their tools working like a charm? After all, happy tools make for happy workers!

| Benefits of Model Calibration | Impact on Machining |

|---|---|

| Improved Accuracy | Leads to better results. |

| Cost Efficiency | Saves money on materials. |

| Time Savings | Reduces rework and delays. |

Factors Influencing Milling Forces

Material properties and their impact on cutting forces. Tool geometry and design considerations.Many things affect how milling forces work during cutting. Material properties play a big role. Hard materials need more force. Softer materials are easier to cut. Tool geometry also matters. The shape and design of cutters influence how they behave. A sharp edge cuts better than a dull one. Here are some key factors to remember:

- Material Hardness: Harder materials need more force.

- Cutting Edge Shape: Sharp edges cut easier.

- Tool Thickness: Thicker tools may resist bending.

What are the important factors in cutting forces?

Material hardness, tool shape, and design all change how much force is needed. Keeping these in mind makes for better results in milling.

Experimental Techniques for Model Calibration

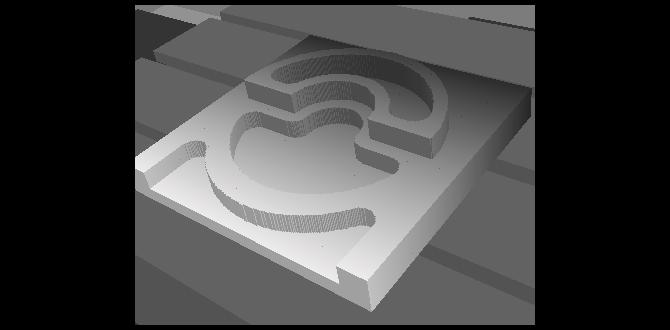

Common experimental setups and methodologies. Data collection and analysis techniques.Different techniques are used to check and improve a milling cutter tool force model. Common setups include using machine tools and sensors to measure forces precisely. Researchers may also use computer simulations to predict how the tool behaves under different conditions.

For data collection, methods like strain gauges and dynamometers collect useful force data. Data analysis involves comparing measured forces to predicted values, using graphs and tables to see differences clearly.

- Machines: CNC machines for accurate testing.

- Sensors: Strain gauges and pressure sensors.

- Analysis tools: Software for graphing results.

What are common experimental setups for model calibration?

Common setups include CNC machines, strain gauges, and pressure sensors. These tools help collect accurate force data for better model calibration.

Challenges in Model Calibration

Common issues faced during the calibration process. Solutions and best practices to overcome these challenges.Calibrating a model can feel like trying to teach a cat to fetch: full of surprises! Common problems include inaccurate data and unexpected variable changes. Thankfully, using well-planned test scenarios and good quality tools can help. Regularly updating your methods is a smart move too, just like keeping your favorite snacks stocked! Check out this table for some quick tips:

| Challenge | Solution |

|---|---|

| Inaccurate Measurements | Use high-quality sensors. |

| Variable Changes | Perform regular check-ups. |

| Data Errors | Double-check all inputs. |

So, take a deep breath, smile, and tackle those calibration challenges like a champ!

Case Studies and Real-World Applications

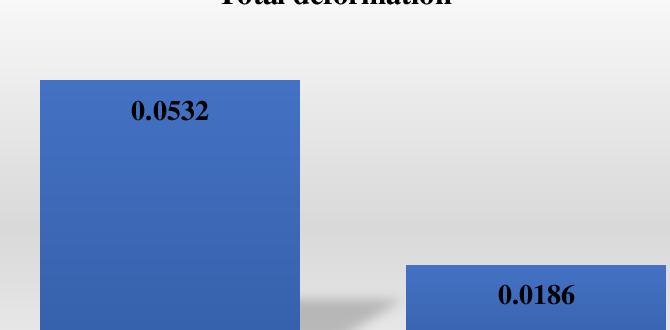

Examples of successful milling cutter tool force model calibrations. Impact of calibration on productivity and costefficiency.Many companies have seen great results from milling cutter tool force model calibrations. For example, a factory calibrated its milling cutter tool and increased production speed by 20%. This saved money and improved quality.

- Reduced Tool Wear: Proper calibration lowers tool damage.

- Better Accuracy: Machines cut materials more precisely.

- Lower Costs: Less waste means more savings.

How does calibration improve machining?

Calibration improves machining by making tools cut better and last longer. This means the work is done right the first time, saving time and materials.

The Future of Milling Cutter Tool Force Models

Emerging trends in force modeling and calibration technology. The role of artificial intelligence and machine learning in enhancing models.The future holds exciting advancements for milling cutter tool force models. Emerging technology will make models more accurate and user-friendly. Artificial intelligence (AI) and machine learning will play a big role. These tools can analyze data quickly, improving the calibration process. Think of AI as a helper, making smart choices based on past data. This can save time and reduce errors in manufacturing.

- AI helps to predict tool behavior.

- Machine learning improves model accuracy.

- Better calibration means higher quality products.

What is the impact of AI on milling cutter models?

AI enhances milling cutter models by making them smarter and more precise. It analyzes large amounts of data quickly. This leads to better predictions and fewer mistakes in machining processes.

Conclusion

In conclusion, calibrating a milling cutter tool force model helps you improve accuracy in machining. By understanding the forces involved, you can optimize performance and reduce mistakes. Remember to test different settings and learn from results. We encourage you to explore more resources on this topic and practice your skills for better results in your projects. Happy milling!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Tool Force Model Calibration:Sure! When we talk about milling cutter tool force model calibration, we’re figuring out how strong the cutting tool is when it works on metal. You want to make sure it’s just right so the tool cuts well and lasts long. To do this, we test different forces and see how the tool reacts. This helps us understand how to make tools better. It’s like adjusting a recipe so that your cookies taste just perfect!

Sure! Just let me know what question you want me to answer, and I’ll be happy to help!

What Are The Key Parameters That Influence The Milling Cutter Tool Force During The Machining Process, And How Do They Vary With Different Materials?The key things that affect the force on a milling cutter are the type of material you’re cutting, the sharpness of the cutter, and how fast you move it. Softer materials, like wood, need less force than harder ones, like metal. If the cutter is dull, it also needs more force. So, if we change materials or how we use the cutter, the force will change too.

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.

How Can Computational Modeling Techniques Be Utilized To Predict Milling Forces, And What Role Does Experimental Data Play In Validating These Models?We can use computer models to guess how strong the force will be when cutting materials. These models use math to show different situations in milling, which is when we cut metal or wood. To make sure our guesses are correct, we need to test them in real life and collect data. This experimental data helps us see if our computer models are right or if they need changes. By mixing both, we get better at predicting milling forces!

Sure! What question would you like me to answer?

What Methods Are Available For Calibrating The Milling Cutter Tool Force Model, And How Do These Methods Compare In Terms Of Accuracy And Efficiency?We can calibrate the milling cutter tool force model using a few methods. One way is to use real tests with machines to measure the forces. Another way is to use computer models to predict the forces. Real tests are usually more accurate but can take more time and resources. Computer models are faster but might be a bit less accurate.

Sure! Please provide the question you want me to answer.

How Does The Tool Geometry, Such As Rake Angle And Cutting Edge Radius, Affect The Calibration Of Milling Cutter Force Models?The rake angle and cutting edge radius of a milling cutter help us understand how it cuts materials. A larger rake angle lets the cutter slice more easily, reducing the force needed. The cutting edge radius changes how smooth the cut is and affects how much force we measure. By adjusting these measurements, we can make better models to predict how much effort the cutter will need. This makes our work more accurate and saves time.

Sure! I can help with that. Just let me know what question you want answered!

What Are The Implications Of Inaccurate Tool Force Modeling On Machining Performance Metrics Like Surface Finish And Tool Wear?If we don’t model tool forces correctly, it can mess up how well the machine works. You might get a rough surface instead of a smooth one. The tool can wear out faster, too, which means you have to replace it more often. This can cost more money and take more time. So, it’s really important to get those models right!