Have you ever wondered how precise machines make tiny parts? A milling cutter toolholder is a vital part of this process. It holds the cutter steady while it works on metal or wood. But not all toolholders are the same. Taper accuracy can make a huge difference in how well they perform.

Imagine a race car. If the tires aren’t aligned perfectly, the car can’t win the race. The same idea applies to milling cutter toolholders. If the taper isn’t accurate, it can cause mistakes and slow things down. That’s why knowing more about taper accuracy is essential.

Did you know that even a small error in the toolholder can lead to big problems? It can affect the quality of the final product. In this article, we’ll explore why taper accuracy matters in milling cutter toolholders. Get ready to dive into a world where precision counts!

Milling Cutter Toolholder Taper Accuracy: Ensuring Precision

Milling Cutter Toolholder Taper Accuracy

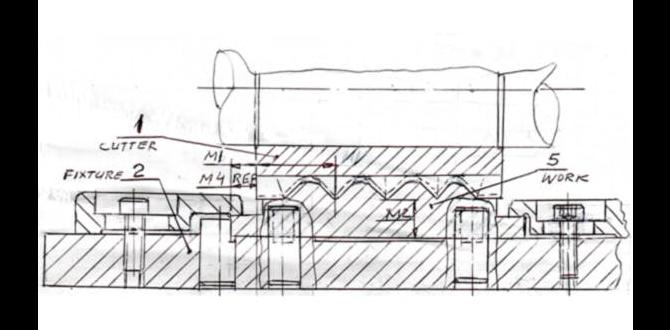

Milling cutter toolholder taper accuracy is crucial for precise machining. A well-designed taper ensures that the tool fits snugly, reducing vibrations during operation. Have you ever wondered why some cuts are smoother than others? This accuracy plays a big role! A small change in taper can lead to significant differences in performance. Choosing the right toolholder improves efficiency and extends tool life. Remember, a precise fit means a happier workshop and better results!Understanding Taper Accuracy in Toolholders

Definition of taper accuracy in milling cutter toolholders. Importance of taper accuracy in machining processes.Taper accuracy in toolholders means how well the tool fits into the holder at a specific angle. This fit is important for the tool to work properly. When taper accuracy is good, it helps machines make parts correctly. Poor accuracy can lead to mistakes and wasted materials.

- Better fitting tools improve productivity.

- Correct angles ensure smooth operation.

- Less wear on tools leads to longer life.

Without good taper accuracy, machines may not cut materials correctly. This can cause delays and added costs. In the world of machining, accuracy really matters!

What is taper accuracy?

Taper accuracy is how well a milling cutter fits into its holder at the right angle. This fit is critical for effective cutting and machining.

Why is taper accuracy important?

Taper accuracy is essential because it directly affects the quality of the finished product. Accurate fits prevent errors, reduce waste, and extend the tool’s lifespan.

Factors Affecting Taper Accuracy

Discussion on material properties and wear. Influence of manufacturing processes on taper precision.Different elements can affect how accurately a taper fits. First, material properties play a big role. Some materials wear out faster than others, changing the shape over time. On the other hand, manufacturing processes can make or break taper precision. If the tools aren’t made well, expect a wobbly fit! Imagine trying to balance a spoon on your nose—tricky, right? Here’s a quick look at how these factors interact:

| Factor | Effect on Taper Accuracy |

|---|---|

| Material Wear | Increases taper deviation over time |

| Manufacturing Quality | Affects initial taper fit and longevity |

Measuring Taper Accuracy

Instruments and techniques for accurate measurement. Best practices for calibration and verification.Precision is a big deal in measuring taper accuracy. Tools like dial indicators, calipers, and laser measurement devices help us get the readings right. Regular calibration is key to keeping these instruments sharp, much like how a chef sharpens his knife before slicing a tomato. Don’t forget to check your setup frequently and verify results with reliable standards. After all, we want everything to fit perfectly, not like a square peg in a round hole!

| Measurement Tool | Accuracy Level |

|---|---|

| Dial Indicator | High |

| Caliper | Moderate |

| Laser Measurement | Very High |

So next time you measure, remember: it’s all about the right tools and regular checks. Who wants surprise gaps in their projects? Nobody, that’s who!

Impact of Taper Accuracy on Machining Performance

Relationship between taper accuracy and tool life. Effect on surface finish and dimensional tolerances.Taper accuracy plays a big role in machining. It affects how long tools last, how good the finished surfaces look, and how tight the measurements are. Accurate taper means better tool life. This helps avoid wear and tear on the tool, saving money over time. It also leads to smoother surfaces and precise sizes for parts. If the taper is off, problems can happen.

- Better taper accuracy means:

- Longer tool life

- Improved surface finish

- Finer dimensional tolerances

- Fewer mistakes and waste

How does taper accuracy affect tool life?

Better taper accuracy leads to longer tool life. This means tools can be used for a longer time without breaking down. Accurate taper reduces unnecessary wear on the tool.

Why is surface finish important?

Good surface finish is key for quality parts. It helps parts fit well and look nice. Taper accuracy directly enhances this finish.

What are dimensional tolerances?

Dimensional tolerances show how precise measurements are. High taper accuracy ensures parts are made correctly every time. This results in fewer errors and rework.

Improving Taper Accuracy in Toolholders

Techniques for enhancing precision during toolholder production. Maintenance practices to preserve accuracy over time.To improve accuracy during toolholder production, focus on two main areas: techniques and maintenance practices. First, adjust machine settings carefully. Use high-quality materials for better precision. Regular checks help keep standards high.

For maintenance, follow these tips:

- Clean toolholders regularly.

- Inspect for wear and tear.

- Store tools properly to avoid damage.

These actions help maintain taper accuracy over time. Regular upkeep saves money in the long run. A good plan ensures your tools perform their best.

How can you keep toolholders accurate over time?

Regular cleaning and careful storage of toolholders help keep them accurate. Check for any wear often. This way, you can catch problems before they become bigger.

Case Studies: Real-World Applications

Examples of industries benefiting from high taper accuracy. Analysis of specific machining scenarios highlighting taper issues.Many industries benefit from high taper accuracy in milling cutter toolholders. For example, automotive and aerospace sectors rely on precise machining for safety. In these fields, even small errors can lead to big problems. Accurate toolholders ensure proper fit and performance, reducing material waste. Here are a few scenarios:

- In the automotive industry, accurate taper helps with engine parts.

- Aerospace manufacturers need tight tolerances for wing components.

- Medical devices require precision to ensure patient safety.

Each case shows how important high taper accuracy can be. It’s key to improving quality and making better products.

What industries use milling cutter toolholder taper accuracy?

Industries like automotive, aerospace, and medical device manufacturing use taper accuracy for safety and quality. Accurate tools help make products that fit perfectly and work well.

Future Trends in Milling Cutter Toolholder Technology

Innovations aimed at improving taper accuracy. Predictions for the evolution of toolholder designs and standards.New technology is changing milling cutter toolholders. Innovations are focused on making taper accuracy better. For example, new materials help fit pieces more tightly. This could make machines work faster and more precisely. Also, toolholder designs are expected to evolve. Manufacturers may use smart sensors that adjust for better accuracy. Some trends to watch include:

- Advanced sensor technology for real-time monitoring.

- Lightweight materials for easier handling.

- Standardization across different brands.

The future looks bright for milling toolholders as better designs come into play. Better accuracy means better work results!

How will taper accuracy improve in the future?

Future innovations will likely enhance taper accuracy through smart sensors and new materials.

Conclusion

In summary, milling cutter toolholder taper accuracy is crucial for precision in machining. It directly affects the quality of your work. To improve accuracy, regularly check and maintain your tools. Consider exploring additional resources about toolholder types and selection. This way, you’ll enhance your skills and achieve better results in your projects. Keep learning and practicing!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Toolholder Taper Accuracy:Milling cutter toolholder taper accuracy means how well a tool fits into a machine. If the tool is snug and straight, it works better. A tight fit helps us make precise cuts. It’s important to check the taper often to keep everything working nicely. This way, we can create smooth and exact shapes in our projects.

Sure! Please ask your question, and I’ll help you with a short answer.

What Are The Key Factors That Influence The Accuracy Of The Taper In Milling Cutter Toolholders?The key factors that make the taper in milling cutter toolholders accurate are fit, material, and wear. First, the fit is how well the parts match together. If they fit well, they work better. The material affects strength, too; some metals hold shape better than others. Lastly, wear happens over time as tools are used. If they wear down, they won’t be as accurate anymore.

How Does The Precision Of The Taper Affect The Overall Machining Performance And Tool Life In Milling Operations?The taper is the part that fits the tool to the machine. When the taper is precise, it holds the tool tightly. This helps the tool cut better and last longer. If the taper is not precise, the tool can be loose, which causes problems and wears it out quickly. So, a good taper is important for using tools effectively in milling.

What Measurement Techniques Are Commonly Used To Assess The Accuracy Of Toolholder Tapers?To check how accurate toolholder tapers are, we can use a few different tools. First, we can use a dial gauge, which measures tiny distances. We also use calipers to measure the outside and inside parts precisely. Lastly, you might see us use a test bar, which helps us see if the taper fits well. These tools help us make sure everything works perfectly!

How Can Improper Taper Accuracy Lead To Issues Such As Vibration Or Tool Pull-Out During Milling?If the taper isn’t accurate, it means the tool won’t fit well. This can cause the tool to shake, which is called vibration. When the tool shakes too much, it can come loose, which is called tool pull-out. If this happens, your work might not be smooth, and you can break things. So, having the right fit keeps everything steady and works better.

What Are The Recommended Practices For Maintaining Taper Accuracy In Milling Cutter Toolholders Over Time?To keep taper accuracy in milling cutter toolholders, you should clean them after each use. Store them carefully in a dry place to prevent damage. Check them regularly for any chips or dirt. Using a torque wrench can help you tighten them correctly. This way, your tools will work better for a long time!