Have you ever wondered how machines cut metal so smoothly? The secret often lies in a tiny tool called a milling cutter. But there’s more to it than just spinning blades. One important concept is z-axis load management.

Think of a roller coaster. Each twist and turn puts pressure on the tracks. In milling, the z-axis load is similar. It affects how well the cutter works. When the load is balanced, the cutter performs better and lasts longer. But if the load is too high, problems can arise.

Imagine you are playing with a toy car. If you push too hard, it might break. The same goes for milling cutters. Managing the z-axis load helps prevent damage and keeps everything running smoothly. So, what happens if we don’t pay attention to this? That’s what we will explore in this article!

Effective Milling Cutter Z-Axis Load Management Strategies

Milling cutter z-axis load management plays a crucial role in machine performance. Properly managing this load can enhance cutting efficiency and tool lifespan. Did you know that using the right feed rate and depth can significantly reduce wear and tear on your tools? By monitoring loads, operators can prevent costly breakdowns and improve part quality. Understanding the balance of forces helps in achieving better results, ultimately saving time and money in the long run.

Understanding Z-Axis Load in Milling

Definition of Zaxis load in machining processes. Importance of managing Zaxis load for precision and efficiency.

Z-axis load in machining refers to the force applied along the vertical axis of a milling cutter. It influences how the cutter bites into the material. Managing this load is vital for achieving precision and efficiency. A balanced load helps prevent damage to the cutter and workpiece, leading to better results. Here are some key points to remember:

- Control ensures accurate cuts.

- Reduces wear and tear on tools.

- Contributes to smoother operations.

Understanding how this load affects your work can make a big difference. It’s like tuning a musical instrument for the best sound!

What is the impact of Z-axis load?

The impact of Z-axis load is significant; it can affect the quality of the cutting process and can determine the life of the tools. Proper management leads to smoother operations and higher quality products.

Factors Influencing Z-Axis Load

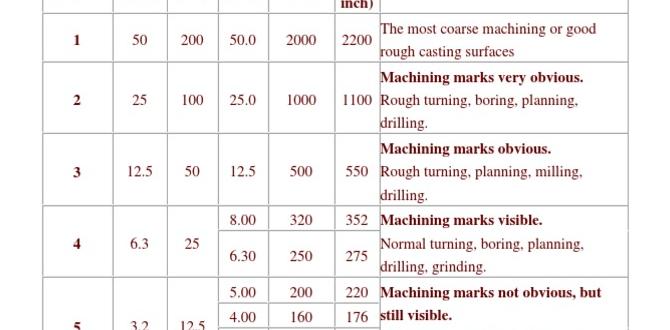

Relationship between cutting speed, feed rate, and load. Material properties and their effect on Zaxis dynamics.

Many things affect how the z-axis load works. One big factor is the cutting speed and feed rate. A faster cutting speed can lower the load on the milling cutter. However, a higher feed rate can increase the load. Material properties also matter. Some materials are harder or softer, which affects how the z-axis moves. Understanding these factors helps in better milling cutter z-axis load management.

How does cutting speed and feed rate affect load?

Faster cutting speeds can often lead to lower loads. However, when the feed rate is too high, it might increase the load on the tool. Finding the right balance is key.

Key Material Properties Affecting Z-axis Dynamics:

- Material hardness

- Density

- Moisture content

Measuring Z-Axis Load in Milling Operations

Tools and technologies for monitoring load. Metrics and indicators of effective load management.

In milling operations, understanding the z-axis load is like getting the perfect slice of pizza: too much weight makes it flop. Tools like load sensors and software monitor this load closely. They give us key metrics such as maximum load and average load, which help us keep things balanced. Here’s a quick look:

| Metrics | Indicators |

|---|---|

| Maximum Load | Prevents overloading |

| Average Load | Ensures smooth operation |

This load management keeps your tools happy and your cuts clean, just like a well-tuned dance party!

Best Practices for Effective Z-Axis Load Management

Techniques for optimizing cutter placement and alignment. Recommended adjustments based on load readings.

To get the best results from your milling cutter, proper placement and alignment are key. Start by adjusting your cutter to the right height. A tiny shift can make a huge difference! Always check those load readings. If the load is too high, you might need to adjust the cutter’s position. And remember, too much downward pressure can make your equipment grumpy. Keep it light and breezy!

| Load Reading | Suggested Adjustment |

|---|---|

| High | Lift cutter higher |

| Low | Lower cutter slightly |

Common Challenges in Z-Axis Load Management

Identifying issues such as vibration and tool wear. Strategies for troubleshooting loadrelated problems.

Managing z-axis load is like juggling with sharp knives—exciting but risky! Common issues include vibration and tool wear. Vibration can cause poor cuts, while tool wear leads to lively fireworks of metal shavings! To troubleshoot these problems, checking the machine settings is essential. Using the right tool for the job also helps. And for fun? Just imagine your milling machine as a dance partner—listen to its rhythm, and adjust accordingly!

| Issue | Solution |

|---|---|

| Vibration | Check settings and stabilize the machine. |

| Tool Wear | Use the correct tool and inspect frequently. |

Advanced Techniques in Z-Axis Load Management

Use of simulation software for predictive load analysis. Implementation of adaptive control systems to enhance performance.

New technology helps manage the z-axis load better. Simulation software can predict how loads will act. This means fewer surprises when working. Also, adaptive control systems adjust on the fly. They enhance performance by responding to changes. This results in smoother operations and longer equipment life.

What is predictive load analysis?

Predictive load analysis uses software to forecast how loads will behave. It helps in planning tasks without unexpected issues.

Benefits of Adaptive Control Systems:

- Improved Efficiency: Machines work better.

- Fewer Breakdowns: Reduces wear and tear.

- Better Precision: Cuts are more accurate.

Case Studies: Successful Z-Axis Load Management in Industry

Examples of companies improving productivity through load management. Lessons learned and applicable strategies from case studies.

Some companies have found fun ways to boost productivity through smart z-axis load management. For example, a factory named “Cutting Edge Tools” saw a 30% increase in their output by adjusting their milling machines for better load distribution. Another company, “Precision Parts,” learned that managing their loads led to fewer tool breaks. This is like keeping your cookie jar high so nobody eats them all at once!

| Company | Productivity Boost | Key Strategy |

|---|---|---|

| Cutting Edge Tools | 30% | Adjusting load distribution |

| Precision Parts | 20% | Reducing tool breaks |

These examples show that good load management can help keep machines running smoothly, just like a well-balanced seesaw! Companies learned that small changes led to big gains. The lesson? Don’t underestimate the power of smart management!

Future Trends in Milling Cutter Z-Axis Load Management

Innovations in milling technology and their implications on load management. The role of automation and artificial intelligence in enhancing Zaxis efficiency.

Exciting changes are coming in milling cutter technology! With innovations popping up like popcorn in a microwave, load management is getting a smart upgrade. Automation and artificial intelligence are becoming best buddies in this field, helping to boost Z-axis efficiency. Imagine machines that can think, adapt, and adjust weight all on their own! It’s like giving your milling cutter a brain. Soon, we might find our machines are more organized than we are!

| Trend | Impact |

|---|---|

| Smart Sensors | Improve load detection |

| AI Algorithms | Enhance decision-making |

| Data Analytics | Optimize load balancing |

Stay tuned for thrilling changes that might make your milling cutter the coolest tool in your workshop!

Conclusion

In conclusion, managing the z-axis load with milling cutters is essential for better performance and longer tool life. You can improve machining results by adjusting the load properly and using the right techniques. We encourage you to explore further resources on this topic to enhance your understanding and skills. Start experimenting with your milling cutter today!

FAQs

What Factors Influence The Z-Axis Load On A Milling Cutter During Machining Operations?

The Z-axis load on a milling cutter is influenced by how hard the material is, the speed we use, and how deep we cut. If we push harder or go deeper, the load increases. Also, the type of cutter and its shape can change the load too. When we choose these factors wisely, we can make smoother cuts.

How Can The Proper Adjustment Of Spindle Speed Impact The Z-Axis Load And Overall Tool Performance?

When we adjust the spindle speed correctly, it helps the tool work better and last longer. The Z-axis load is how heavy the tool feels while cutting. If the speed is too fast or too slow, the tool can get stuck or break. Finding the right speed makes cutting easier and smoother. This helps us do our jobs well and keeps everything safe.

What Techniques Can Be Employed To Minimize Z-Axis Load While Ensuring Precision In Milling Operations?

To minimize Z-axis load in milling, you can use lighter tools. This helps reduce weight while cutting. You can also set up the machine correctly to avoid too much pressure. Keeping the tool sharp is important, too. Sharp tools cut better and reduce strain on the machine.

How Can The Selection Of Cutting Tools And Materials Affect Z-Axis Load Management In Milling Applications?

Choosing the right cutting tools and materials is important for milling. When we use a tool that is too heavy or strong, it can push down too hard on the material. This makes it hard for the machine to control how much weight is on it. If we pick lighter tools or better materials, we can help the machine work better and longer. It’s all about finding the right tool that matches what we’re working with!

What Role Does Machine Rigidity And Stability Play In Managing Z-Axis Load During High-Speed Milling Processes?

Machine rigidity means it’s strong and doesn’t bend easily. Stability means it stays in place without shaking. In high-speed milling, we need this strength and steadiness to handle the weight pushing down on the tool, called the Z-axis load. If the machine is not rigid or stable, it can cause mistakes or damage. So, a strong and steady machine helps us cut better and safer.