Have you ever watched a machine work and wondered how it stays so precise? One key to its success is the milling tool crash prevention system. This system helps protect expensive machinery from damage. Imagine a situation where a tiny mistake could ruin a whole project. That’s where this amazing technology comes in.

Many people don’t know that milling machines can crash. When they do, it can be costly and time-consuming. However, with the right crash prevention system, these accidents can be avoided. Isn’t it interesting that something so small can save so much money?

In this article, we will explore how milling tool crash prevention systems work. You’ll learn why they are so important in manufacturing. We’ll uncover fascinating facts that show their impact on the industry. Get ready to dive into the world of milling tools and discover how they keep things running smoothly!

Milling Tool Crash Prevention System: Enhancing Safety And Efficiency

Milling Tool Crash Prevention System

A milling tool crash prevention system helps protect machines and tools during operation. Ever wondered how accidents happen? Often, tools collide with materials due to operator errors or equipment malfunctions. This smart system detects potential crashes before they happen, allowing quick adjustments. It reduces downtime and costly repairs. Imagine working without worrying about damaging expensive equipment! With the right system, you can improve safety and boost productivity on the shop floor.Understanding Milling Tool Crashes

Definition and common causes of milling tool crashes. Impact on productivity and equipment.Milling tool crashes happen when machines hit an obstacle or operate incorrectly. This can break tools and damage equipment. Common causes include:

- Incorrect tool settings

- Tool wear

- Wrong materials

These crashes hurt productivity. They stop work and waste time. According to studies, when tools crash, companies can lose a lot of money. Keeping tools in good shape helps avoid these issues.

What is a milling tool crash?

It’s **a sudden failure** that can lead to broken tools and damaged machines.

What causes milling tool crashes?

Crashes often occur due to **poor settings, tool wear, or unsuitable materials**.

Importance of Crash Prevention Systems

Benefits of implementing a crash prevention system. Cost savings associated with reducing tool crashes.Implementing a crash prevention system is smart for any milling operation. It helps avoid tool accidents, which can be costly. Think of it as a superhero that saves the day! Fewer tool crashes mean less money spent on repairs and replacements. Imagine saving enough to buy an ice cream truck—sweet, right? The benefits are clear: safer machines, happier workers, and more savings. Investing in these systems pays off big time.

| Benefit | Cost Savings |

|---|---|

| Reduces tool damage | Less repair costs |

| Improves worker safety | Fewer medical bills |

| Increases machine lifespan | Saves replacement costs |

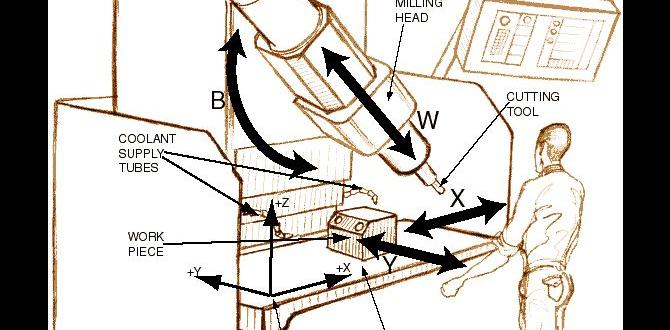

Types of Milling Tool Crash Prevention Systems

Mechanical systems: sensors and physical barriers. Software solutions: realtime monitoring and alerts.Milling tool crash prevention systems come in two main types: mechanical systems and software solutions. Mechanical systems use sensors and physical barriers to stop crashes. Imagine sensors like tiny safety nets, catching any falls before they happen! On the other hand, software solutions offer real-time monitoring and send alerts if something goes wrong. Think of this like your smart fridge, reminding you that you’re out of milk—only here, it warns you before your tools go bump in the night!

| Type | Description |

|---|---|

| Mechanical Systems | Utilize sensors and barriers to prevent crashes. |

| Software Solutions | Provide real-time monitoring and alerts for tool safety. |

Key Features to Look for in a Crash Prevention System

Accuracy and response time. Compatibility with various milling machines.Finding the right crash prevention system is important for keeping your milling tools safe. First, check the accuracy and response time. A good system reacts quickly to avoid crashes. Slow systems? They can be as reliable as a three-legged chair! Next, ensure it has compatibility with various milling machines. You want a system that fits as snugly as your favorite pair of shoes. This prevents the hassle of mismatches, so you can focus on your work without worrying!

| Feature | Why It Matters |

|---|---|

| Accuracy | Helps prevent tool crashes |

| Response Time | A quick reaction saves the day! |

| Compatibility | Works with many machines |

Case Studies: Successful Implementation of Crash Prevention Systems

Examples from different manufacturing sectors. Measurable outcomes and improvements.Many factories have improved their work by using crash prevention systems. For example, a car manufacturing plant noticed fewer accidents after installing these tools. This change led to a 20% decrease in downtime. In another case, a metal machine shop increased production by 15% by avoiding tool crashes. These examples show how these systems make work safer and more efficient.

- 20% decrease in downtime in car industry

- 15% increase in production in metalworking

What are the benefits of using crash prevention systems?

These systems improve safety, boost productivity, and reduce costs.

Challenges in Implementing Crash Prevention Systems

Potential integration issues with existing systems. Training considerations for staff.Implementing crash prevention systems is not always smooth sailing. One challenge is figuring out how these new tools fit with what’s already in place. Sometimes, they are like trying to fit a square peg into a round hole. Also, teaching staff to use the new system is crucial. Nobody wants a “bump and crash” situation because someone forgot to read the manual! Proper training can make all the difference.

| Challenges | Solutions |

|---|---|

| Integration Issues | Conduct thorough assessments and tests. |

| Staff Training | Provide hands-on workshops and clear guides. |

Statistics show that up to 40% of employees feel unprepared when new systems are introduced. Taking time to train can turn that around!

Future Trends in Milling Tool Crash Prevention Technology

Innovations on the horizon: AI and automation. Predictions for the manufacturing industry.Exciting things are coming in milling tool crash prevention! Imagine AI and robots working together to keep machines safe. These smart tools can predict crashes before they happen. They learn from past mistakes, much like a little kid who touches a hot stove and decides to avoid it next time.

In the future, manufacturers might see fewer crashes and more creativity. Workers can focus on making cool new designs instead of worrying about broken tools. As a bonus, this could save companies a ton of money—up to 20%! Who knew that robots could be the new best friends of the manufacturing world?

| Trend | Benefit |

|---|---|

| AI Integration | Safer operations |

| Automation | Less downtime |

So, buckle up! The future is bright and a little zany, just like a robot dance-off in a factory!

Conclusion

In conclusion, a milling tool crash prevention system can save time, money, and effort. It protects machines from damage and keeps projects running smoothly. We can use sensors and software to monitor tools effectively. You should consider learning more about these systems to enhance your work. Check out resources or guides to deepen your understanding and improve your skills!FAQs

What Are The Key Components Of A Milling Tool Crash Prevention System, And How Do They Function Together To Ensure Machining Safety?A milling tool crash prevention system has a few key parts. First, it uses sensors to detect if the tool gets too close to something. If it does, a computer quickly stops the machine. There are also alarms that warn you if something is wrong. Together, these parts help keep everyone safe while working with machines.

How Can Real-Time Monitoring Technologies, Such As Sensors And Cameras, Be Integrated Into Milling Operations To Detect Potential Crashes Before They Occur?We can use sensors and cameras in milling operations to watch machines closely. These devices can sense when things are too close to each other. If they notice a problem, they send a warning. This helps us stop crashes before they happen. By paying attention to these alerts, we can keep everything running safely.

What Role Does Artificial Intelligence Play In Predicting And Preventing Tool Collisions In Cnc Milling Machines?Artificial intelligence, or AI, helps CNC milling machines work better. It predicts when tools might bump into things. This way, it can stop accidents before they happen. We use AI to make the machines smarter and safer. It checks the machine’s movements quickly and makes adjustments when needed.

What Are The Common Causes Of Tool Crashes In Milling Operations, And How Can A Crash Prevention System Address These Issues Effectively?Tool crashes in milling can happen for a few reasons. Sometimes, the tool hits the wrong part or gets stuck. Other times, the machine moves too fast or isn’t set up right. A crash prevention system helps by checking settings and speeds. It can stop the machine if it senses something wrong. This keeps tools safe and helps us make better parts.

How Can Manufacturers Assess The Effectiveness Of Their Milling Tool Crash Prevention Systems, And What Metrics Should Be Used For Evaluation?Manufacturers can check how well their milling tool crash prevention systems work by looking at a few important things. First, they can count how many crashes happen before and after using the system. Next, they can measure how long it takes to fix machines after a crash. Finally, they should look at worker safety and ask if they feel safe while using the tools. These steps help us see if the systems are really doing their job.