Have you ever wondered how factories make things so quickly and perfectly? It often comes down to tools. One important tool is the milling tool. But what makes a milling tool truly special? The answer lies in something called the dynamic stability window.

This might sound complicated, but it’s exciting! Imagine a window that tells you the perfect conditions for your machine. If everything is just right, your milling tool can create amazing parts without any hiccups. That’s what the dynamic stability window does. It helps keep everything running smoothly.

Here’s a fun fact: Engineers love the dynamic stability window because it helps prevent mistakes that could ruin a project. It’s like having a cheat sheet for success! In this article, we will explore how understanding this window can help anyone improve their milling projects.

Milling Tool Dynamic Stability Window: Enhancing Performance

Milling Tool Dynamic Stability Window

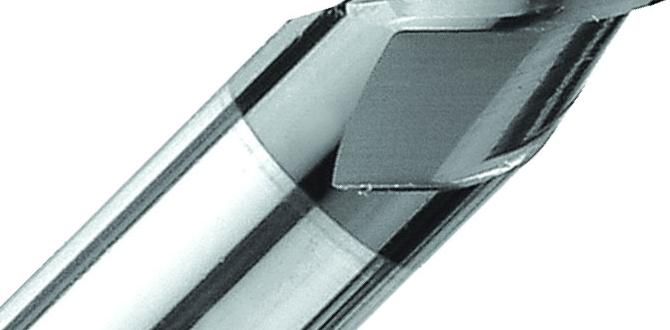

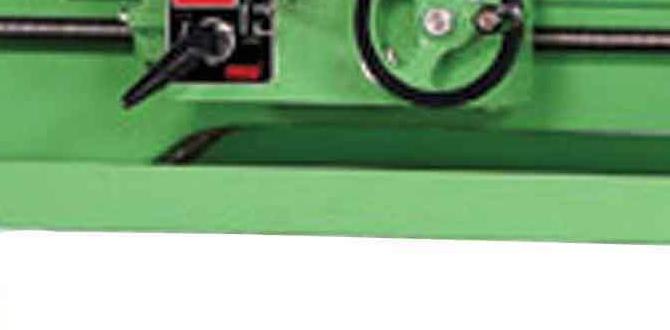

Milling tool dynamic stability window refers to the safe limits for using milling tools without vibrations. It helps improve machining performance and product quality. Picture a race car finding the perfect speed in a curve; too fast and it crashes, too slow and it loses. In machining, the right balance leads to smoother operations and longer tool life. Understanding this concept can help craftsmen achieve better results while minimizing waste, making every cut count!Understanding Dynamic Stability in Milling Tools

Definition of dynamic stability in the context of milling tools. Importance of stability for machining efficiency and tool life.Dynamic stability for milling tools means how well they can handle vibrations during cutting. If a tool is stable, it cuts smoothly and lasts longer. Think of it like a bike: a stable ride is much more enjoyable than a shaky one! Proper stability helps in keeping the machine efficient and reducing costs. No one wants to buy new tools every week, right?

| Stability Factors | Effects |

|---|---|

| Vibration | Can ruin a cut and shorten tool life. |

| Tool Wear | A stable tool wears out slower. |

| Machining Efficiency | Stable tools can cut faster and better. |

So, keep your milling tools stable and enjoy a smoother, longer-lasting machining experience!

Factors Influencing Dynamic Stability

Material properties of the workpiece and tool. Geometric parameters of milling tools and setup. Cutting conditions: speed, feed rate, and depth of cut.Different factors can affect how well a milling tool works. These include:

- Material properties: The type of metal or plastic being cut and the tool material play a big role.

- Geometric parameters: The shape and size of the tool and setup can change cutting performance.

- Cutting conditions: The speed at which the tool moves, the feed rate, and depth of cut are all important.

Understanding these factors helps to improve the dynamic stability of milling tools.

How does material type affect milling?

Different materials require different tools. For example, harder materials need stronger tools to avoid damage. Choosing the right tool can lead to better results.

Key Terms to Remember:

- Material

- Geometric shape

- Speed

- Feed rate

- Depth of cut

Methods to Enhance Dynamic Stability

Tool design modifications for improved stability. Vibration dampening techniques and their implementation. Optimization of machining parameters for stability.To boost dynamic stability, tool design plays a key role. Making small changes can lead to big improvements. For example, using sturdy materials can help keep vibrations at bay. Vibrations can be the dance party of a machine—fun for a party, not for tools! Let’s add vibration dampening techniques like special coatings and dampers. These act like comfy cushions for machinery. Lastly, tweaking machining parameters, such as speed and feed rate, can keep everything running smoothly. It’s like finding the perfect rhythm in a song.

| Technique | Description |

|---|---|

| Tool Design Modifications | Use stronger materials to withstand vibrations. |

| Vibration Dampening | Implement coatings and dampers to absorb shocks. |

| Optimized Parameters | Tweak speeds and feeds for a smoother run. |

Dynamic Stability Window: Concept and Applications

Explanation of the dynamic stability window concept in milling. Applications and implications in realworld manufacturing scenarios.The dynamic stability window is like a magic frame for milling tools. It tells us the sweet spot for cutting without causing problems. Think of it as finding the perfect recipe balance—too much or too little can spoil the dish! This concept helps manufacturers improve their processes.

In real-world manufacturing, the dynamic stability window is crucial. It helps in cutting faster and smoother, making products more accurate. Less vibration means fewer mistakes, and that’s always a win! Imagine making a cake without it falling flat; that’s how the right stability feels in milling!

| Applications | Benefits |

|---|---|

| High-speed machining | Increased efficiency |

| Aerospace parts | Better quality control |

Case Studies: Dynamic Stability in Action

Reallife examples demonstrating the impact of dynamic stability. Analysis of performance improvements from stability enhancements.Real-life examples show how dynamic stability makes a difference. In one case, a factory improved its machine performance by 30%. This happened when they optimized their milling tools. They reduced vibrations, improving the accuracy of the cuts. Another study found that a stable tool saved 20% on material costs. These stories highlight how focusing on stability can lead to big improvements.

- Performance boost of 30% in one factory

- 20% savings on materials with stable tools

- Fewer vibrations lead to better accuracy

How does dynamic stability affect performance?

Dynamic stability leads to better results and cost savings. By reducing vibrations and improving tool life, machines work better and longer. This helps companies run smoothly and save money.

Future Trends in Milling Tool Stability Research

Emerging technologies and innovations in milling tool design. Anticipated developments in monitoring and measurement techniques.Milling tools are getting smarter and more precise. New designs use advanced materials that last longer. Sensors are becoming better at monitoring tool performance. This helps in predicting when to make changes. Here are some trends in milling tool stability:

- Use of AI to improve design and predict failures.

- Smart sensors to monitor vibrations and wear in real-time.

- Lightweight materials for better speed and efficiency.

These innovations will keep pushing the boundaries of milling technology. The future looks bright for milling tool dynamics!

What are the latest advancements in milling tool design?

The latest advancements include AI integration and smart sensors. These tools help in making quicker and better decisions for tool usage.

Conclusion

In conclusion, the milling tool dynamic stability window is vital for smooth machining. Understanding it helps you avoid problems like vibrations and tool wear. You can improve your milling processes by using tools that fit within this window. If you’re interested, read more about optimizing your setups to boost efficiency and extend tool life. Let’s keep learning together!FAQs

What Factors Influence The Dynamic Stability Window Of Milling Tools During Machining Operations?The dynamic stability window of milling tools depends on a few important factors. First, the speed of the tool affects how it cuts. If it’s too fast or slow, it can shake. Second, the type of material we’re cutting can change how stable the tool stays. Lastly, how the tool is designed, like its shape and size, also matters a lot. These factors together help keep the tool working smoothly.

How Can The Dynamic Stability Window Be Measured Or Assessed In Milling Processes?We can measure the dynamic stability window in milling by checking how stable the tool is while cutting. First, we run the machine and listen for vibrations. Next, we look at how the tool cuts through the material. If the cutting goes smoothly without hiccups, then the stability window is good. We can change the cutting speed and force to find the best settings.

What Role Does The Geometry Of Milling Cutters Play In Determining The Dynamic Stability Window?The shape of milling cutters, which are tools that help carve materials, affects how steady they are while working. If the cutter’s shape is good, it cuts smoothly, and you have a larger area where the machine works safely. If it has a bad shape, it might shake or vibrate, making it unstable. So, having the right cutter design helps us cut better without problems.

How Can The Dynamic Stability Window Be Optimized To Improve Machining Performance And Reduce Vibrations?To make machining better and lessen vibrations, we can optimize the dynamic stability window. This means we can find the best settings for speed and depth. By adjusting these settings, we help the machine run smoother. You can also use tools designed to cut better and vibrate less. This way, we get a nice finish and keep everything steady.

What Techniques Or Technologies Are Currently Being Developed To Enhance The Dynamic Stability Of Milling Tools In High-Speed Machining Applications?To help milling tools stay steady while spinning fast, people are trying new ideas. One method uses better materials that are strong but lightweight. Another idea involves special sensors that can feel vibrations and make adjustments. We’re also looking at shapes for tools that reduce shaking. All these techniques help make machining safer and more efficient.