Have you ever wondered how products are made with precision? The answer often lies in the tools used for shaping and cutting materials. One tool that stands out is the milling tool. It plays a big role in manufacturing.

In today’s fast-paced world, everyone wants things done quickly and accurately. This is where high efficiency milling comes into play. Imagine cutting metal or wood with little waste and a perfect finish. Sounds amazing, right?

High efficiency milling patterns can do just that. They allow manufacturers to save time while creating high-quality parts. Have you seen a factory? Machines are constantly busy, making items for us. This efficiency helps keep up with our demands.

As we explore the world of milling tools and their high efficiency patterns, you’ll uncover the secrets behind their design. You’ll see how they shape the products we use every day. Get ready to discover more about this fascinating tool and its impact on our lives!

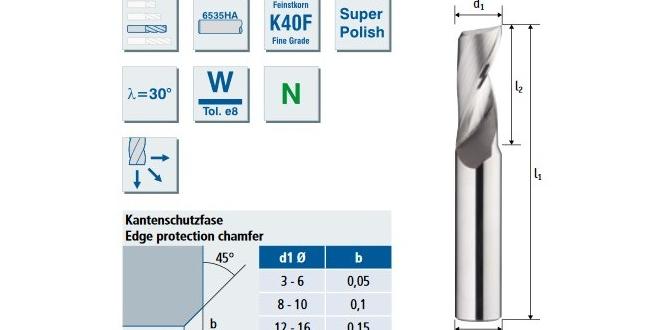

Milling Tool: High Efficiency Milling Pattern Explained Milling Tools Are Pivotal In The Manufacturing And Engineering Sectors, Especially When Seeking Precise And Efficient Machining Solutions. High-Efficiency Milling Patterns Have Emerged As A Popular Approach To Enhance Productivity And Reduce Operational Costs During Machining Processes. Understanding The Intricacies Of Milling Tools And How To Implement High-Efficiency Milling Can Transform Production Workflows And Improve Outcomes. What Is High Efficiency Milling? High Efficiency Milling (Hem) Is A Technique That Allows For Higher Material Removal Rates While Maintaining Optimal Tool Longevity And Reducing Machine Wear. This Method Leverages Advanced Cutting Strategies, Utilizing Appropriate Milling Tools Designed Specifically For Consistent And Efficient Material Removal. It Combines Powerful Tooling With Suitable Feed Rates And Depth Of Cuts To Maximize Efficiency. Key Aspects Of Milling Tools 1. **Material Composition**: The Choice Of Materials In Milling Tools Impacts Their Hardness, Wear Resistance, And Performance In High-Efficiency Scenarios. Carbide And High-Speed Steel Are Popular Choices Due To Their Effectiveness Under High-Stress Conditions. 2. **Geometry**: Tool Geometry Plays A Crucial Role In Defining The Milling Pattern. Features Such As Cutting Edge Angles, Flutes, And Coating Determine How Effectively A Milling Tool Can Engage With Material. 3. **Chip Load**: Calculating The Ideal Chip Load Is Vital For High Efficiency Milling. It Ensures That The Milling Tool Operates Within Its Capacity, Facilitating Effective Material Removal While Extending Tool Life. Benefits Of High Efficiency Milling Patterns 1. **Increased Productivity**: By Employing High-Efficiency Milling Patterns, Manufacturers Can Achieve Faster Cycle Times And Greater Output Levels Compared To Traditional Milling Methods. 2. **Cost Reduction**: Efficient Material Removal Translates To Lower Operational Costs, As Both Machining Time And Energy Consumption Are Decreased. 3. **Improved Tool Life**: Hem Minimizes Wear On Milling Tools, Resulting In Prolonged Tool Life, Which Can Significantly Reduce The Frequency Of Tool Replacement And Associated Costs. 4. **Enhanced Surface Finish**: Using Optimized Milling Patterns Often Leads To Superior Surface Finishes In Machined Parts, Reducing The Need For Secondary Operations. Implementing High Efficiency Milling To Successfully Implement High-Efficiency Milling Patterns In Your Operations, Consider The Following Steps: – **Choose The Right Tools**: Select Milling Tools Specifically Designed For Hem. – **Optimize Parameters**: Fine-Tune Feed Rates, Depths Of Cut, And Spindle Speeds According To The Material And Tooling Specifications. – **Monitor Tool Performance**: Regularly Analyze Tool Wear And Machining Outcomes To Adapt Your Processes And Continuously Improve Efficiency. Conclusion Understanding And Utilizing High-Efficiency Milling Patterns With The Right Milling Tools Can Greatly Enhance Machining Processes. By Focusing On Optimal Tooling, Geometry, And Operational Parameters, Industries Can Maximize Productivity And Reduce Costs, Ultimately Leading To Improved Profitability And Competitiveness In The Market.

Milling Tool High Efficiency Milling Pattern

Milling tools designed for high efficiency use special patterns. These patterns help create smoother surfaces and faster cutting speeds. Have you ever wondered how machines make precise shapes? With the right tool, they can cut materials quickly and accurately. High efficiency milling also reduces waste, which is great for the environment. This means better products and less cleanup. Heres a fun fact: using these tools can save time and money in production. Isn’t that impressive?Understanding High Efficiency Milling (HEM)

Definition and principles of high efficiency milling. Comparison between traditional milling and HEM.High efficiency milling (HEM) makes cutting materials faster and easier. It uses special tools and techniques to remove more material with less effort. This is different from traditional milling, which takes longer and requires more energy. In fact, HEM can boost productivity by up to 50%! Imagine finishing a big project with time to spare, maybe even to enjoy a cookie or two!

| Aspect | Traditional Milling | High Efficiency Milling |

|---|---|---|

| Material Removal Rate | Slower | Faster |

| Tool Wear | Higher | Lower |

| Energy Consumption | More | Less |

So, whether you’re milling wood or metal, HEM is like having the superhero version of a milling tool. Faster, stronger, and ready to save the day!

Advantages of High Efficiency Milling

Increased material removal rates. Improved tool life and reduced wear.High efficiency milling brings many benefits. One big advantage is increased material removal rates. With this method, more material comes off the workpiece faster, saving time. Another perk is improved tool life and reduced wear. Tools last longer, which cuts costs. This means less time spent replacing tools and more time working. Overall, high efficiency milling boosts productivity and saves money!

What are the main advantages of high efficiency milling?

There are two key benefits:

- Faster material removal helps complete jobs quickly.

- Longer tool life results in less frequent tool changes.

Key Factors Influencing HEM Performance

Tool geometry and material selection. Cutting parameters (speed, feed rate, depth of cut).Choosing the right tool for milling is like picking the perfect pizza topping; it really matters! Tool geometry and material are key. Depending on the job, using the right materials can make your work fly. Cutting parameters, such as speed and depth, are equally important. A good balance helps keep the machine happy and the job efficient. Too fast, and you might just end up with a mess! Too slow? Eternal regret awaits!

| Factor | Effect on Performance |

|---|---|

| Tool Geometry | Enhances cutting efficiency |

| Material Selection | Increases durability and precision |

| Speed | Affects chip removal rate |

| Feed Rate | Controls the depth of cut |

HEM Patterns and Their Applications

Different milling patterns suited for HEM. Case studies of successful applications in various industries.Milling tools with high-efficiency milling (HEM) patterns are changing the game in various industries. These patterns make cutting smoother and faster, like gliding on butter. Some popular milling patterns include spiral, zig-zag, and linear. Each pattern has its special job, from metal to wood.

In construction, the zig-zag pattern keeps machines humming like a happy bee. For aerospace, the spiral pattern helps cut parts with amazing precision. Check out this table for a glimpse of successful applications:

| Industry | Milling Pattern | Success Story |

|---|---|---|

| Aerospace | Spiral | Lightweight parts made faster. |

| Automotive | Zig-zag | Boosted production speed. |

| Construction | Linear | More accurate cuts, less waste. |

These tailored milling patterns show that good things come in patterns! Funny, right?

Techniques for Optimizing HEM Processes

Tips for setting up machines and tools correctly. Common mistakes to avoid in HEM operations.Setting up machines and tools correctly is key for great results. Always check your tool height and angle. This helps your machines cut material better. Here are some common mistakes to avoid:

- Not checking tool wear.

- Ignoring machine setup instructions.

- Using the wrong cutting speeds.

By paying attention to these details, you can boost your high efficiency milling (HEM) work. Remember, small adjustments can lead to big improvements!

What are tips for machine setup?

Check the height, angle, and sharpness of your tools. This ensures efficient cutting and reduces mistakes.

How to avoid common mistakes?

- Always read the user manual.

- Regularly inspect your tools.

Future Trends in High Efficiency Milling

Innovations in milling technology. Predictions for the evolution of HEM practices and tools.Get ready for the future of milling! Exciting new tools and tech are popping up like popcorn. Innovations in milling technology promise to make high efficiency milling (HEM) faster and smarter. Imagine machines that think for themselves, making less waste and saving time. Experts predict that soon, we’ll see tools that can even change shapes! Talk about a stylish drill! With high efficiency milling, we might just be able to slice our work time in half. So keep your helmets on, because the future is looking bright!

| Innovation | Benefit |

|---|---|

| Smart Sensors | Better precision and less error |

| Automated Tool Changes | Saves time, no more awkward tool dance |

| Eco-Friendly Materials | Less waste, greener planet |

Conclusion

In conclusion, the milling tool high efficiency milling pattern boosts productivity. It helps you make precise cuts quickly and reduces waste. Using this pattern, you can achieve better results in your projects. Next, consider trying out different tools or techniques to see what works best for you. For more tips, keep exploring resources on milling and machining!FAQs

What Are The Key Design Features Of Milling Tools Used In High-Efficiency Milling (Hem) Patterns?Milling tools used in high-efficiency milling (HEM) have special design features. First, they have sharp edges to cut better. Second, they are often lighter, so they move faster. Third, their shapes help remove chips quickly, which keeps things cool. These features help make the job quicker and easier!

How Does The Choice Of Cutting Parameters Affect The Performance And Efficiency Of High-Efficiency Milling?The cutting parameters are like the rules for a game. They decide how fast and deep we cut into the material. If we choose the right parameters, we can make smoother cuts and use less energy. This helps us finish our work faster and better. If we pick the wrong settings, we might waste time and make rough cuts.

What Materials Are Most Suitable For Milling Tools Utilized In High-Efficiency Milling Applications?For high-efficiency milling, we often use materials like high-speed steel and carbide. High-speed steel is tough and can handle heat well. Carbide is even harder and lasts a long time. These materials help us make precise cuts quickly and efficiently. They are perfect for getting the job done!

How Can High-Efficiency Milling Contribute To Reducing Production Costs And Improving Cycle Times In Manufacturing Processes?High-efficiency milling uses special tools to cut materials faster and more accurately. This means we can make parts quicker, so we finish jobs sooner. When we work faster, we save money because we use less energy and materials. By making fewer mistakes, we also spend less time fixing problems. Overall, we get things done faster and cheaper!

What Advancements In Technology Have Impacted The Development Of Milling Tools Specifically Designed For High-Efficiency Milling Patterns?New technology has made milling tools better for high-efficiency milling. We now have stronger materials that last longer. Smart software helps us plan cutting paths more easily. Also, machines today can work much faster and more precisely. These advancements help us cut shapes more quickly and with less waste.