Have you ever watched a machine cut through metal? It’s fascinating! But did you know that the milling tool maximum chip thickness plays a big role in how well that machine works? Imagine trying to slice through a loaf of bread. If you press too hard, your slice might crumble. The same idea applies in milling. If the chip thickness is too big, it can ruin the piece you’re working on.

Understanding maximum chip thickness can help anyone working with milling tools. It can improve efficiency and precision. But what does it really mean? How does it affect the quality of the final product? Let’s dive into this exciting topic!

Milling Tool Maximum Chip Thickness: Understanding Its Impact

Milling Tool Maximum Chip Thickness

Understanding milling tool maximum chip thickness helps improve machining efficiency. This measurement indicates the largest amount of material a cutting tool can remove in one pass. If the chip thickness is too high, it can cause tool wear or breakage. Properly adjusting this thickness can lead to smoother finishes and longer tool life. Did you know that optimizing chip thickness can save both time and money in production? Knowing this simple detail can make a big difference in manufacturing.Understanding Maximum Chip Thickness

Define maximum chip thickness in the context of milling.. Explain its significance in machining processes..In milling, understanding maximum chip thickness is key. It tells us how thick each tiny slice of material can be. Think of it like making the perfect sandwich; too much filling and it gets messy! The right thickness helps keep tools sharp and machines running smoothly. If it’s too thick, things can break faster than one might expect, leading to downtime and extra costs. Remember, a satisfied milling tool is a happy milling tool!

| Maximum Chip Thickness | Significance |

|---|---|

| Defines tool limits | Prevents damage |

| Affects surface finish | Improves quality |

| Optimizes machining | Saves time and money |

Factors Influencing Maximum Chip Thickness

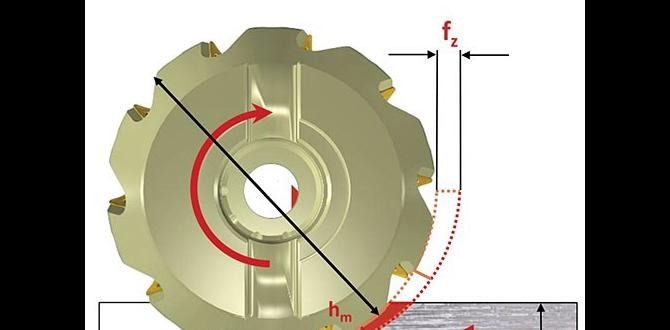

Discuss parameters like cutting speed, feed rate, and tool geometry.. Explore material properties and their effect on chip thickness..Many factors affect how thick the chips are when using milling tools. Cutting speed matters a lot; it helps cut smoothly and shapes the material better. The feed rate, or how fast the tool moves, also plays a role. If it’s too fast, chips can become thick. Tool geometry, such as the shape and angle of the blade, changes how the tool meets the material. Material properties, like hardness, influence chip thickness as well. Softer materials create thinner chips, while harder ones make thicker ones.

What are the main factors that influence maximum chip thickness?

Key factors influencing maximum chip thickness include cutting speed, feed rate, tool geometry, and material properties.Here are some important points:

- Cutting speed determines how quickly the tool slices the material.

- Feed rate affects the amount of material removed at one time.

- Tool geometry influences the cutting action and chip shape.

- Material properties such as hardness, determine how chips are made.

Importance of Controlling Chip Thickness

Analyze the impact on tool wear and lifespan.. Examine effects on surface finish and dimensional accuracy..Controlling chip thickness is important for keeping your milling tool happy. Thicker chips can make tools wear out faster, like a pair of new shoes on a muddy field. A well-managed chip thickness can also improve surface finish and make your measurements more accurate. Imagine if your birthday cake came out lopsided! Nobody wants that. Let’s look at how chip thickness affects everything:

| Impact Factor | Effect of Thick Chips | Effect of Controlled Chips |

|---|---|---|

| Tool Wear | Increases | Decreases |

| Surface Finish | Poor Quality | High Quality |

| Dimensional Accuracy | Less Accurate | More Accurate |

By managing chip thickness, you can help your milling tool look better, work longer, and avoid silly mistakes. Remember, nobody likes a grumpy tool!

Techniques to Optimize Chip Thickness

Detail strategies for feed rate adjustments and cutting parameters.. Introduce advanced tooling options and configurations..To make milling tools work better, start by adjusting the feed rate. Faster feed rates can help improve chip thickness. It’s also important to fine-tune cutting parameters. Using the right speed and depth can lead to better results.

Consider advanced tooling options, like high-performance cutters or special coatings. They can help achieve the best chip thickness.

- Experiment with different feed rates to find the perfect speed.

- Use tooling with specific designs for your materials.

- Adjust cutting speed based on material and tool type.

How can feed rate adjustments optimize chip thickness?

Feed rate adjustments can help create a consistent chip thickness. A faster rate often leads to thinner chips, while a slower rate allows for thicker chips.Common Mistakes Impacting Chip Thickness

Identify errors in machine setup and operation.. Highlight the consequences of neglecting chip thickness control..Errors in machine setup can lead to big problems. If a tool isn’t set right, it can cut too deep or too shallow. This makes chip thickness uneven. Missing or loose parts can also cause issues. If a machine isn’t running smoothly, it affects the whole job. Neglecting chip thickness control can lead to:

- Lower quality of the finished product

- Increased wear on the tools

- Higher costs for repairs

In the long run, these mistakes can lessen the lifetime of tools. Each small error can create a chain reaction that impacts production.

What are common errors in machine setup?

Common errors include incorrect tool alignment, wrong speeds, and improper feed rates. These often lead to uneven chip thickness and production issues.

Real-world Applications and Case Studies

Present examples from various industries utilizing optimal chip thickness.. Share success stories and their outcomes from effective chip management..Many industries benefit from using the right chip thickness. Here are some real-world examples:

- Aerospace: Companies optimize chip thickness to save weight, improving fuel efficiency.

- Automotive: Engine parts created with precise chip management see better performance and longer life.

- Manufacturing: Factories using optimal thickness report lower costs and less waste.

Success stories prove the value of effective chip management. Those who adjust their processes often enjoy significant gains in productivity and quality.

Why is chip thickness important in different industries?

Chip thickness matters because it impacts performance and cost. Different industries need specific thickness to meet their goals.

Future Trends in Milling Technology

Discuss innovations in tooling materials and designs.. Speculate on advances in automation and their implications for chip thickness management..Exciting changes are on the horizon for milling technology! New materials are being used for tooling, making them tougher and longer-lasting. Think of them as superheroes in the milling world. These innovations will help manage maximum chip thickness better than ever. Automation is also stepping in, turning machines into smart helpers. Imagine a robot that knows just how thick to make those chips—no more guesswork! This could save time and prevent waste. Isn’t that neat?

| Innovation | Benefit |

|---|---|

| New Tooling Materials | Longer lifespan, better performance |

| Automation | Improved chip thickness control |

These advancements mean smoother operations and happier machinists. Who doesn’t want to work smarter, not harder?

Conclusion

In conclusion, understanding milling tool maximum chip thickness helps improve machining efficiency. Remember, thicker chips can lead to more wear and tear. You can optimize tool life by adjusting depth and feed rates. We encourage you to explore more about cutting tools and their settings to enhance your skills. A little research can go a long way in your metalworking journey!FAQs

Here Are Five Related Questions On The Topic Of Milling Tool Maximum Chip Thickness:Milling tools cut materials to make shapes. The maximum chip thickness is the thickest piece that comes off while cutting. If the chip is too thick, it can damage the tool or make a mess. We want to keep the chip thin for better cutting and less breakage. Always check the tool to avoid problems!

Sure! Just ask your question, and I’ll answer it simply and clearly for you.

What Factors Influence The Determination Of Maximum Chip Thickness In Milling Operations?The maximum chip thickness in milling is affected by a few important factors. First, the speed of the cutter matters. If you go faster, the chips can be thicker. Second, the type of material you are cutting changes how thick the chips can be. Finally, the sharpness of the cutter also plays a role. A sharp cutter can help make thinner chips.

How Does The Geometry Of A Milling Cutter Affect The Maximum Chip Thickness During The Machining Process?The shape of a milling cutter changes how thick the chips of metal are when we cut. A cutter with a sharp angle makes thinner chips, while a flat one makes thicker chips. If we want smoother surfaces, we can use cutters with special shapes. So, the cutter’s design helps us control how much metal is removed. This helps in making better parts more easily.

What Are The Implications Of Exceeding The Maximum Chip Thickness On Tool Performance And Workpiece Quality?If we exceed the maximum chip thickness, our tools can get damaged faster. This happens because they work too hard. When tools are damaged, they can’t cut well, making the workpiece, or the thing we’re making, less sharp or smooth. We want our tools and pieces to be in good shape, so it’s best to stick to the right chip thickness.

How Can Manufacturers Optimize Cutting Parameters To Control Maximum Chip Thickness In Milling Applications?Manufacturers can change cutting parameters to control chip thickness. First, they can adjust the speed of the machine. If you go faster, you make thinner chips. Next, they can change how deep the cutter goes into the material. If you cut less deep, the chips will also be thinner. Lastly, using the right tools helps make the process better.

In What Ways Does Material Type And Hardness Impact The Maximum Chip Thickness Achievable During Milling?The type of material and how hard it is change how thick a chip can be when we cut it. Soft materials, like wood or plastic, allow thicker chips because they are easier to cut. Hard materials, like metal, can’t be cut as easily, so we get thinner chips. If we try to cut too thick, we might break the tool. So, we must choose the right thickness based on the material we are using.