Have you ever wondered how factories make precise parts? It’s all about the tools! One important tool in making parts is the milling tool. But did you know that milling tool presetting can help improve accuracy?

Imagine trying to build a Lego set without following the instruction manual. It’s tough, right? The same goes for milling. If the tools aren’t set up correctly, you won’t get the right results.

Many shops today face a big challenge. They need to make parts quickly and accurately. This is where milling tool presetting comes in. It ensures that the tools are ready to go before they start working. This saves time and helps make better parts.

In this article, we will explore how milling tool presetting can improve accuracy in production. Are you ready to learn more about this fascinating topic?

Milling Tool Presetting For Accuracy: Enhance Precision Today

Milling Tool Presetting for Accuracy

Milling tool presetting boosts precision in machining. Imagine starting a project with tools perfectly set to the correct measurements. This reduces guesswork and improves efficiency. Using presetting techniques helps avoid mistakes that slow production. Did you know that even a tiny error can lead to big problems in the final product? By ensuring tools are accurately set, manufacturers can save time and money. Embracing milling tool presetting can truly enhance overall quality in machining tasks.Benefits of Accurate Milling Tool Presetting

Improved dimensional accuracy in machined parts. Reduction of setup time and increased productivity.Milling tool presetting can greatly help in many ways. First, it ensures dimensional accuracy in machined parts. This means parts fit together better and work nicely. Second, it cuts down setup time. That means workers can make more parts in less time. This boosts overall productivity. Here are a few benefits:

- Fewer mistakes in measurements

- Parts are ready faster

- Less waste of materials

- More items produced every day

Isn’t it cool how milling tool presetting makes work easier? It helps keep things precise and efficient.

What is the impact of milling tool presetting on production?

It saves time and helps workers make parts faster and better.

Key Factors Affecting Tool Accuracy

Environmental conditions and their impact on tool performance. Importance of tool material and geometry.Several factors play a vital role in how accurately tools operate. First, environmental conditions are crucial. Changes in temperature and humidity can mess with tools, like trying to bake cookies in a snowstorm! Second, the material and geometry of the tool can make a big difference in performance. A tool made from sturdy material is like a superhero in a fight! Its shape also matters—sharp edges and smooth designs lead to better results.

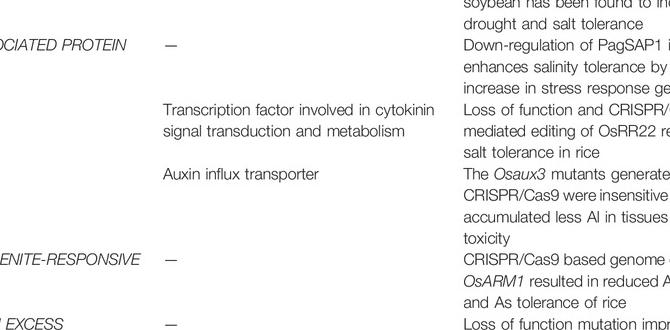

| Factor | Impact on Tool Accuracy |

|---|---|

| Temperature | Can cause expansion or contraction of materials |

| Humidity | Affects the integrity of materials |

| Material | Stronger materials last longer and perform better |

| Geometry | Sharp and precise shapes increase effectiveness |

Techniques for Effective Tool Presetting

Manual vs. automated presetting methods. Calibration processes and tools for optimal accuracy.Choosing the right method for tool presetting can improve your work. You have two main choices: manual and automated presetting. Manual presetting involves hands-on adjustments. It allows for personal touch but may lead to human errors. Automated presetting uses machines to set tools accurately. This method boosts speed and reduces mistakes.

Calibration is also key for accuracy. Check your tools regularly using special calibration tools. These tools ensure that every measurement is exact. Compact and handy models work best for easy use.

What is the difference between manual and automated presetting?

Manual presetting requires hands-on work, while automated presetting uses machines to set tools. Automated allows for faster and more precise adjustments.

Key Steps for Calibration:

- Use a reliable calibration tool.

- Regular checks for accuracy.

- Follow manufacturer guidelines.

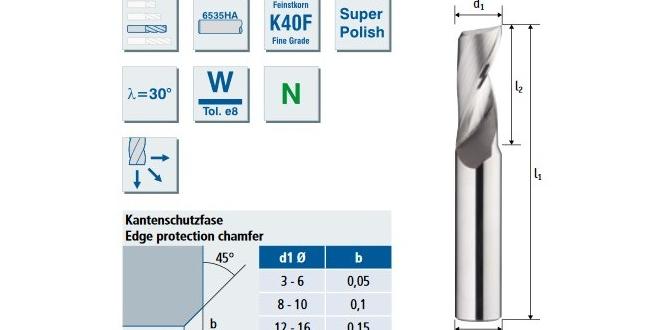

Choosing the Right Equipment for Tool Presetting

Features to consider in a presetting machine. Comparison of popular presetting machines in the market.Picking the right presetting machine is like choosing your favorite dessert; it can be tricky but oh-so-rewarding! First, pay attention to features like accuracy, setup speed, and ease of use. You want one that fits your specific needs like a cozy pair of socks. Next, let’s peek at popular options:

| Machine Model | Accuracy | Setup Time | Price |

|---|---|---|---|

| Model A | ± 0.002 mm | 5 min | $2,000 |

| Model B | ± 0.001 mm | 3 min | $2,800 |

| Model C | ± 0.003 mm | 7 min | $1,500 |

Model B is like the star athlete—fast and precise! But, Model A is a strong contender if you’re on a budget. Remember, the right choice can save time and improve results, making you the superhero of your workshop!

Common Challenges in Tool Presetting and Solutions

Identifying common errors in tool measurement. Troubleshooting tips to enhance accuracy.Tool presetting can be tricky. Common errors often stem from miscalMputations or wrong measurements. Here are some challenges and solutions:

- Incorrect tool lengths: Double-check the measurements before setting.

- Improper alignment: Ensure the tool is perfectly aligned in the holder.

- Environmental factors: Keep the work area clean and stable.

To enhance accuracy, consider these tips:

- Regularly calibrate tools.

- Use quality measuring devices.

- Train staff on best practices.

By addressing these issues, you can improve your milling tool presetting for accuracy.

What are some common measurement errors in tool presetting?

Common measurement errors include incorrect tool length, poor alignment, and external distractions. Identifying these can help you fix problems quickly.

Tips to Troubleshoot Tool Accuracy

- Check your tools regularly.

- Use precise measuring instruments.

- Maintain a tidy workspace.

Integrating Tool Presetting into Manufacturing Workflow

Best practices for seamless integration. Case studies showcasing successful implementation.To make tool presetting work smoothly in manufacturing, follow these best practices:

- Train staff on how to use preset tools correctly.

- Combine tool presetting with other processes for less downtime.

- Use digital tools to track settings easily.

- Keep everything organized to reduce mistakes.

Some companies, like XYZ Corp, improved their production by 30% after adopting tool presetting. This change reduced errors and saved time. It shows the power of having the right tools in place. A good system can really boost efficiency!

What are the benefits of tool presetting in manufacturing?

Tool presetting makes production faster and more accurate. It helps reduce errors and saves time by preparing tools before they are needed on the machine.

Future Trends in Milling Tool Presetting Technology

Advances in digital technology and smart presetting systems. The role of automation and AI in enhancing tool accuracy.The future of milling tool presetting looks bright! Thanks to digital technology, presetting systems are getting smarter. Machines can now communicate better and gather more data. With automation, we can expect **error rates to drop significantly**. Imagine a robot buddy that helps you set up your tools perfectly—like having a helpful sidekick who never complains! Plus, artificial intelligence is stepping in, improving tool accuracy like never before. Who knew machines could have such great sense?

| Trend | Description |

|---|---|

| Smart Presetting | Advanced systems that optimize tool setups. |

| Automation | Reduces human error and speeds up processes. |

| AI Integration | Increases accuracy and predictive capabilities. |

Conclusion

In summary, milling tool presetting is essential for accuracy in machining. It helps you measure tools correctly, which improves your work quality. By using this technique, you save time and reduce mistakes. To get started, try learning about different presetting tools or watch tutorials. With practice, you’ll see the benefits in your projects. Keep exploring to enhance your skills!FAQs

Sure! Here Are Five Questions Related To Milling Tool Presetting For Accuracy:Sure! Here are some answers about milling tool presetting for accuracy. 1. **What is tool presetting?** Tool presetting means getting the tools ready before we use them. We measure them to be sure they are the right size. 2. **Why is it important?** It’s important because it helps us make better and faster parts. When tools are set right, we make fewer mistakes. 3. **How do we check the tools’ size?** We can use special measuring tools to check the size. This way, we know if the tools will cut correctly. 4. **What happens if tools are not set right?** If they are not set right, we might ruin the parts we make. It can also waste time and materials. 5. **Can we measure tools ourselves?** Yes, we can learn to measure the tools ourselves. It’s a good skill to have when we work with machines.

Sure! I can help you with that. Just let me know the question you want me to answer!

What Are The Key Benefits Of Using Tool Presetting In A Milling Operation To Enhance Machining Accuracy?Using tool presetting helps us measure and set up our tools before we start machining. This means we can make sure the tools are just right for the job. It saves time because we don’t have to keep adjusting during work. Also, it helps us make better parts that fit together well. This way, our work is more accurate and we have fewer mistakes.

How Do Different Types Of Tool Presetters (E.G., Manual Vs. Automatic) Impact The Precision And Efficiency Of Milling Processes?Different tool presetters help us prepare tools for milling machines. Manual presetters need you to measure and set tools by hand. This can take more time and might be less accurate. Automatic presetters do the measuring and setting for you, which saves time and often makes things more precise. Using automatic presetters helps us work faster and get better results.

What Measurement Techniques Are Commonly Used In Tool Presetting To Ensure The Accurate Positioning Of Milling Tools?In tool presetting, we use different techniques to measure tools accurately. One method is using calipers, which are devices that measure the distance around objects. Another way is using a tool microscope, which helps us see small details clearly. We also use a height gauge to check how tall the tool is. These methods help make sure tools are set up perfectly for milling!

How Can Operators Troubleshoot Common Issues That Arise During The Tool Presetting Process That May Lead To Inaccuracies In Machining?To troubleshoot problems during tool presetting, we can first check the tool’s position. Make sure it is lined up correctly. Next, inspect the tool for wear or damage. Lastly, confirm that the measuring devices are functioning well. If we follow these steps, we can help prevent mistakes in machining.

In What Ways Can Advancements In Technology, Such As Digital Measuring Devices, Improve Tool Presetting For Milling Applications?Advancements in technology, like digital measuring devices, can help us measure tools more accurately. These devices are quick and easy to use. They can save time because we can check the size of tools instantly. With better measurements, we can make better cuts in milling, which helps everything fit together perfectly. Overall, using these tools makes our work easier and helps us do a great job!